Maintenance – Exmark lazer Z 790 User Manual

Page 46

Maintenance

brake has worn to the point where the clutch no

longer engages consistently, the shim can be removed

to extend the clutch life.

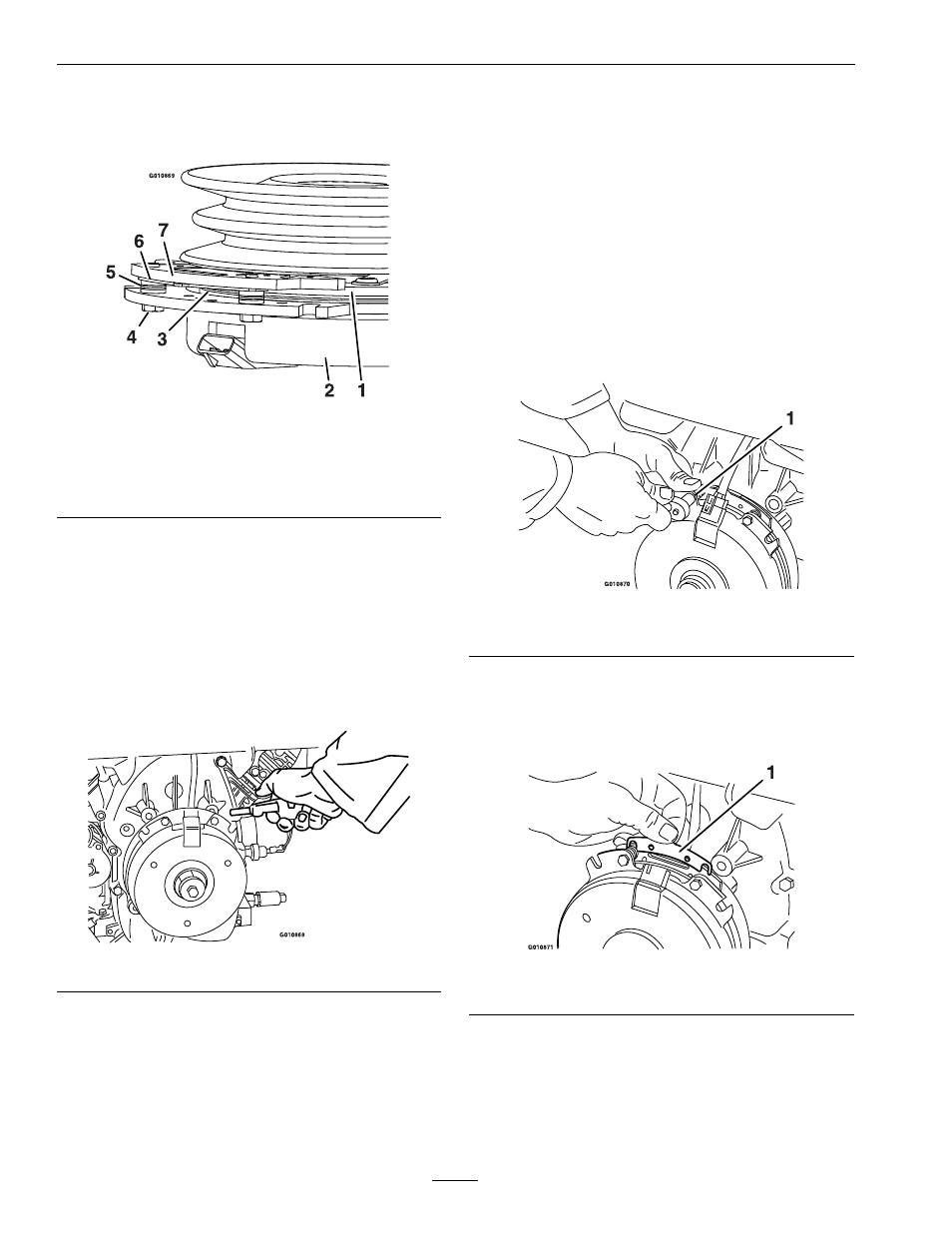

Figure 40

1.

Armature

5.

Brake spacer

2.

Field shell

6.

Re-gap shim

3.

Rotor

7.

Brake pole

4.

Brake mounting bolt

Removing the Shim:

1. Stop engine, wait for all moving parts to stop,

and remove key. Engage parking brake. Allow

the machine to cool completely before starting

these instructions.

2. Using a pneumatic line, blow out any debris

from under the brake pole and around the brake

spacers.

Figure 41

3. Check the condition of the wire harness leads,

connectors, and terminals. Clean or repair as

necessary.

4. Verify that 12V is present at the clutch connector

when the PTO switch is engaged.

5. Measure the gap between the rotor and armature.

If the gap is greater than .04 inch (1 mm), proceed

with the following steps:

A. Loosen both brake mounting bolts one-half

to one full turn as shown below.

Note: Do Not remove the brake pole from

the field shell/armature. The brake pole has

worn to match the armature and needs to

continue to match after the shim is removed

to ensure proper brake torque.

Figure 42

1.

Brake mounting bolt

B. Using needle nose pliers, or by hand, take

hold of the tab and remove the shim (Do Not

discard the shim until proper clutch function

has been confirmed).

Figure 43

1.

Shim

C. Using a pneumatic line, blow out any debris

from under the brake pole and around the

brake spacers.

D. Re-torque each bolt (M6 x 1) to 10 ft-lb (13

N-m) +/-0.5 ft-lb (0.7 N-m).

46