Wiring diagrams, Winter shut down – Essick Air FAD242 User Manual

Page 3

3

110497

Remove

Fig. 7

45°

15°

Entering

Air

Leaving Air

Fig. 6

Black

White

Green

Green

Blue

White w/ Stripe

Installation

Wiring Box

GFCI Receptacle

Unit Cabinet

Required Service Disconnect

In Sight Of Unit

120V - 60Hz - 1PH

Or 240V

Equipment

Ground

120V - 60Hz - 1PH

(Separate Circuit)

L 1

N

L 1

N

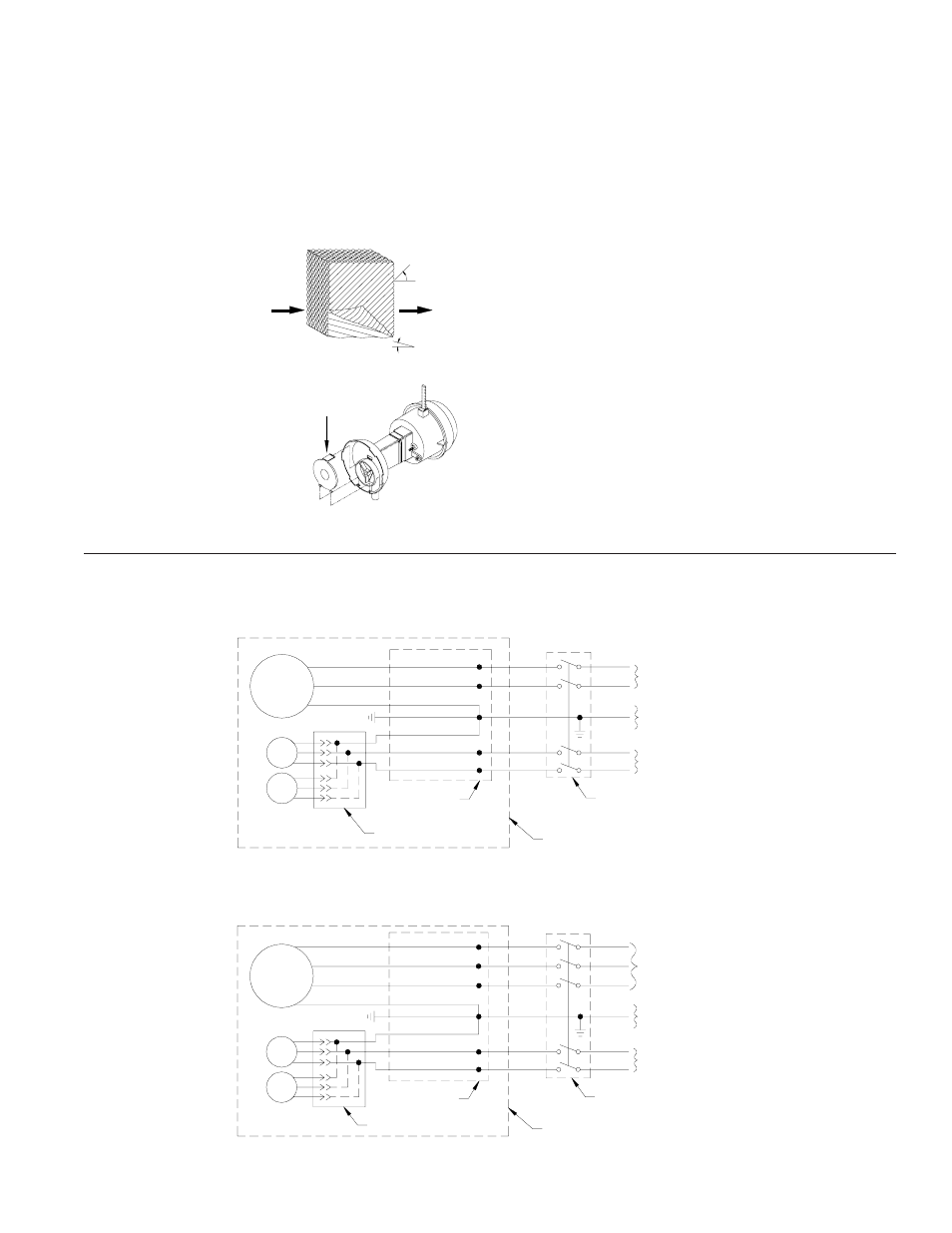

Fig. 8

Fan

Motor

Pumps

White

Black

Red

Green

Green

Blue

White w/ Stripe

Installation

Wiring Box

GFCI Receptacle

Unit Cabinet

Required Service Disconnect In

Sight Of Unit

240V - 60Hz - 3PH

Or 460V

Equipment

Ground

120V - 60Hz - 1PH

Separate Circuit

L 1

L 2

L 3

L 1

N

Fig. 9

Fan

Motor

Pumps

• Pad replacement. The pads should be replaced after 5 years or

before if necessary. To change pads, remove top access panel,

remove grill, and disconnect water delivery tube. Remove water

distributor holder and lift out media sections. Replace with the

same type media. You can purchase them from your dealer.

IMPORTANT: In order to get the best performance from your

cooling pads, they must be installed properly. If you have pur-

chased a pad with two equal angles, the following instructions can

be disregarded. Pads must always be installed with the steeper

flute angle sloping down towards the air entering side (Fig. 6). The

reason is simple. The

steeper angle puts more

water on the hot, dry, dirty

side of the pad where it is

needed most. It also coun-

teracts the tendency of the

air to push the water to-

ward the back of the pad.

• Cleaning pumps. Cleaning the

pumps is necessary once a year at

start-up. For your safety, discon-

nect from power source and unplug

pump. Remove the pump from

the mount bracket. Remove the

base of the pump (Fig. 7). Clean

the pump and turn the impeller to

ensure free operation. Remove the

pump spout and check for any blockage. After cleaning, reinstall

the base onto the pump. Reattach the pump to the mount in the

cooler to ensure that the pump will not overturn. Do not forget to

replace the spout and water delivery tube onto the pump outlet.

NOTE: The pump has automatic reset thermal protection. The

pump motor will stop if it overheats. The pump will operate

normal again after obstruction is cleared.

• Check bleed-off valve to be sure it is not clogged.

Winter Shut Down

• Drain water. Always drain all of the water out of the cooler and

water supply line when not in use for prolonged periods, and par-

ticularly at the end of the season. Keep the water line disconnected

from both the unit and water supply so that water will not seep

into the line and freeze.

• Disconnect from power supply when not in use for extended

periods of time.

• Cover unit. To protect the life of the finish, a cover for the unit is

suggested in extended periods of non use.

By following the operating, installation, and maintenance suggestions

as outlined, you can get many years of efficient and satisfactory

service from your cooler. In the event additional information is de-

sired, your dealer will be more than glad to assist you in every possible

way.

Wiring Diagrams

For 1 or 2 HP, 3 Phase Motor

For 1 or 2 HP, 1 Phase Motor