Enviro Bistro 4500 C-10124 User Manual

Page 11

S

IDE

B

URNER

I

NSTALLED

O

NTO

C

ART

A

SSEMBLY

(O

PTIONAL

):

Components Required:

● Rolling cart with engine

● (2) Shelf gussets

● Cast side burner grill (2 pieces)

● Side Burner

● Side burner porcelain diffuser cap

● Side shelf top or corian cutting board

● (4) 1⁄4” stainless steel nuts

● (10) 1⁄4” x 1⁄2” stainless steel bolts

● (10) 1⁄4” stainless steel lock washers

The side burner must be installed on the right side. The initial installation steps for the side burner are very similar

to the side shelf so you may refer to Figure 18.

1. Attach the two (2) shelf gussets (formed edges pointing in) onto the front and rear of the right side panel, using

four (4) bolts and four (4) lock-washers through the inside of the side shelf into pre-threaded inserts already

installed in the side of the cart.

2. Place the side burner on the shelf gussets and install four (4) bolts, four (4) lock-washers, and four (4) nuts

through the holes in the bottom lip of the side burner and the corresponding hole at the top of the shelf gussets.

DO NOT TIGHTEN THESE BOLTS ENTIRELY, THIS WILL HELP WITH ALIGNMENT FOR NEXT STEP.

3. Install two (2) bolts and two (2) lock-washers through the side of the side burner, accessed through the open

bottom of the side burner, into the pre-threaded inserts already installed in the side of the engine assembly.

4. Using a 1⁄4” socket or nut driver and a

5

/

32

” Allen key tighten all the fasteners.

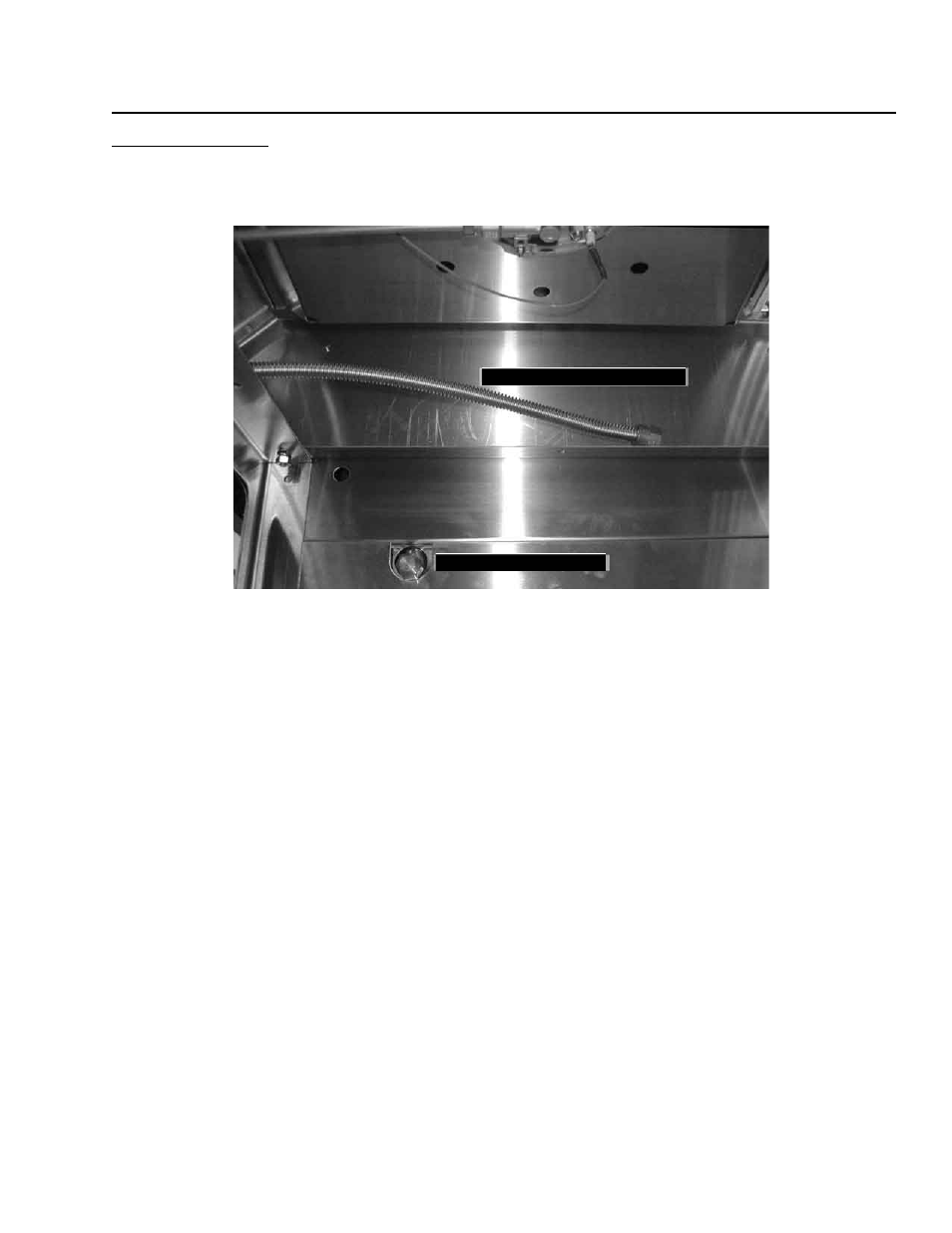

5. Once the side burner has been installed the gas line must be connected. Using a

11

/

16

” wrench remove the cap

installed on side burner outlet on the right side of the engine (see Figure 19).

6. Attach the flexible stainless steel gas line to the side burner outlet using a 3⁄4”.

7. When the gas has been attached to the Bistro 4500 (see “Hooking Up To Gas Supply” section), turn on the

main gas supply and perform a leak test. Using a liquid dish soap and water solution, spray or brush on all gas

connections. If large bubbles are present this is the sign of a gas leak. Re-tighten gas connections and leak test

once again until there are no signs of bubbling.

11

Figure 19