Motion control neutral lock pivot, Adjustment, Motion control neutral lock pivot adjustment – Exmark LAZER Z 4500-471 User Manual

Page 41: Motion control handle adjustment, Motion control full forward tracking adjustment, Maintenance

Maintenance

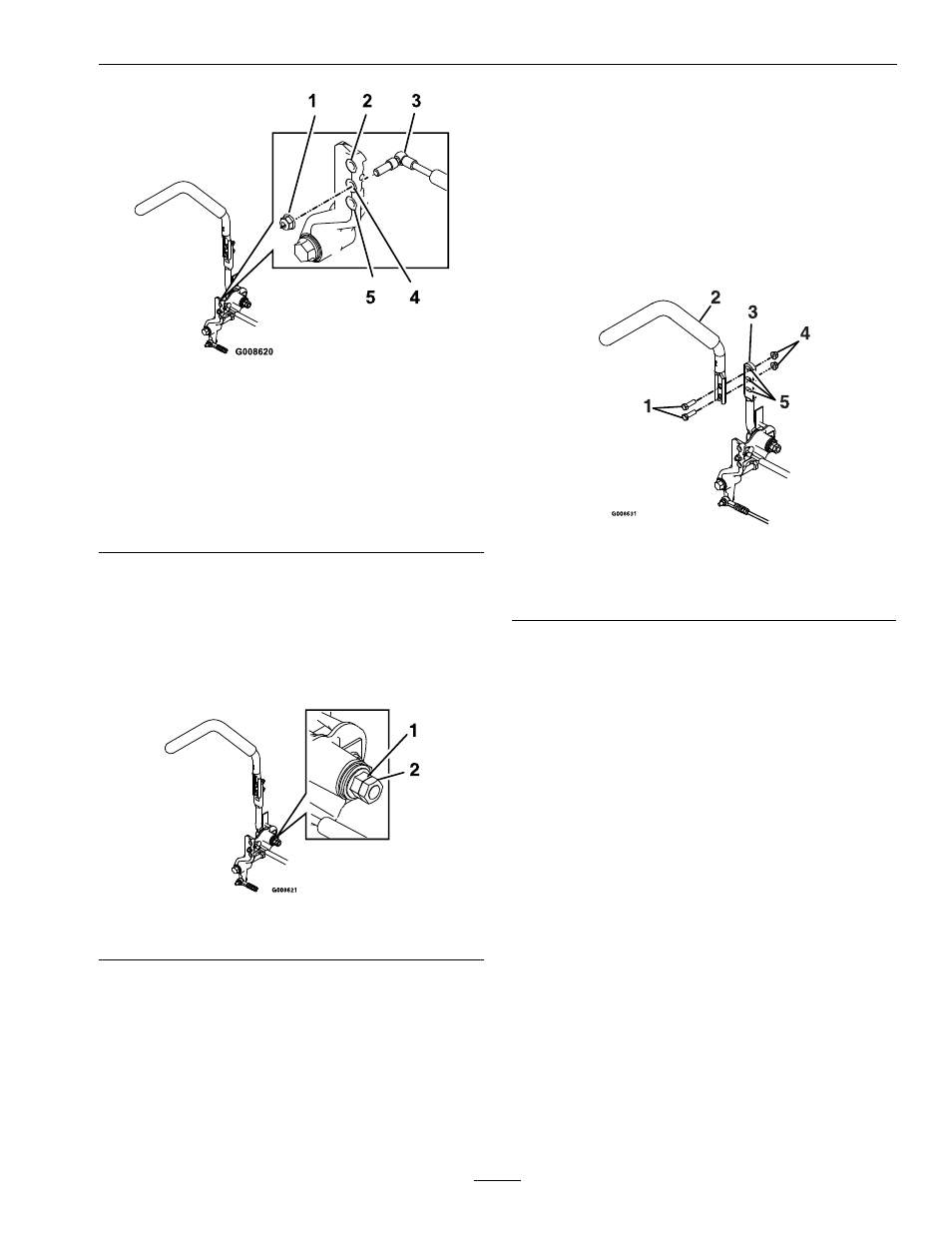

Figure 32

RH Motion Control Shown

1.

Torque nyloc nut to 200 in-lb (16.7 ft-lb). Bolt must

protrude past end of nyloc nut after torque. A T-40 Torx

bit will be necessary to hold the stud from turning.

2.

Most resistance (firmest feel)

3.

Damper

4.

Medium resistance (medium feel)

5.

Least resistance (softest feel)

Motion Control Neutral Lock

Pivot Adjustment

The flanged nut can be adjusted to obtain a more

desired motion control lever resistance (Figure 33).

Figure 33

1.

Flanged nut

2.

Jam nut

1. Loosen the jam nut.

2. Tighten or loosen the flanged nut to the desired

feel.

For more resistance, tighten the flanged nut.

For less resistance, loosen the flanged nut

3. Tighten jam nut.

Motion Control Handle

Adjustment

Adjusting the height:

The motion control levers can be adjusted higher or

lower for maximum operator comfort.

1. Remove the two bolts holding the control lever to

the control arm shaft (Figure 34).

Figure 34

1.

Bolts

4.

Nuts

2.

Control lever

5.

Slotted holes

3.

Control arm shaft

2. Move the control lever to the next set of holes.

Secure the lever with the two bolts.

3. Repeat the adjustment for the opposite control

lever.

Adjusting the Tilt

The motion control levers can be tilted fore or aft for

maximum operator comfort.

1. Loosen the upper bolt holding the control lever

to the control arm shaft.

2. Loosen the lower bolt just enough to pivot the

control lever fore or aft Figure 34. Tighten both

bolts to secure the control in the new position.

3. Repeat the adjustment for the opposite control

lever.

Motion Control Full Forward

Tracking Adjustment

If the machine travels or pulls to one side when the

motion control levers are in the full forward position,

adjust the cover plates.

1. Loosen the screws on a cover plate (see Figure 35).

41