Horizontal vertical round – Earlex HV2900 User Manual

Page 4

SET UP

• Fill the Paint Container (12) with the product to be sprayed. Stir well (as mentioned previously) and strain to

remove any bits which will interfere with a smooth consistent spray.

• Make sure the Paint Container Seal (10) and Pick-up Tube (11) are firmly fitted into the base of the Spray Gun.

• Screw the Paint Container (12) to the base of the Spray Gun and tighten accordingly.

• Start with the Paint Flow Adjuster (9) at its minimum setting so the Trigger can not be pulled. Do not forget that

the Paint Flow Adjuster controls the quantity of paint sprayed (Fig.4).

• Uncoil the air Hose and attach it to the back of the Spray Gun and the other end to the Spray Station.

• Uncoil the power cable and attach the plug to the mains supply.

• Switch the Spray Station on. This will immediately cause some air to be produced, which is quite NORMAL.

However, none of the product will be sprayed until the Spray Gun Trigger is pulled.

• Very important: when spraying for the first time, we recommend that you always leave the motor unit to run for

1 to 2 minutes before applying the product. Do not forget that the Paint Flow Adjuster controls the quantity of

paint sprayed (Fig.5).

ALWAYS MAKE SURE THAT THE MOTOR UNIT IS ON A RIGID SURFACE AND FREE FROM DUST.

4

SPRAYING

HORIZONTAL

VERTICAL

ROUND

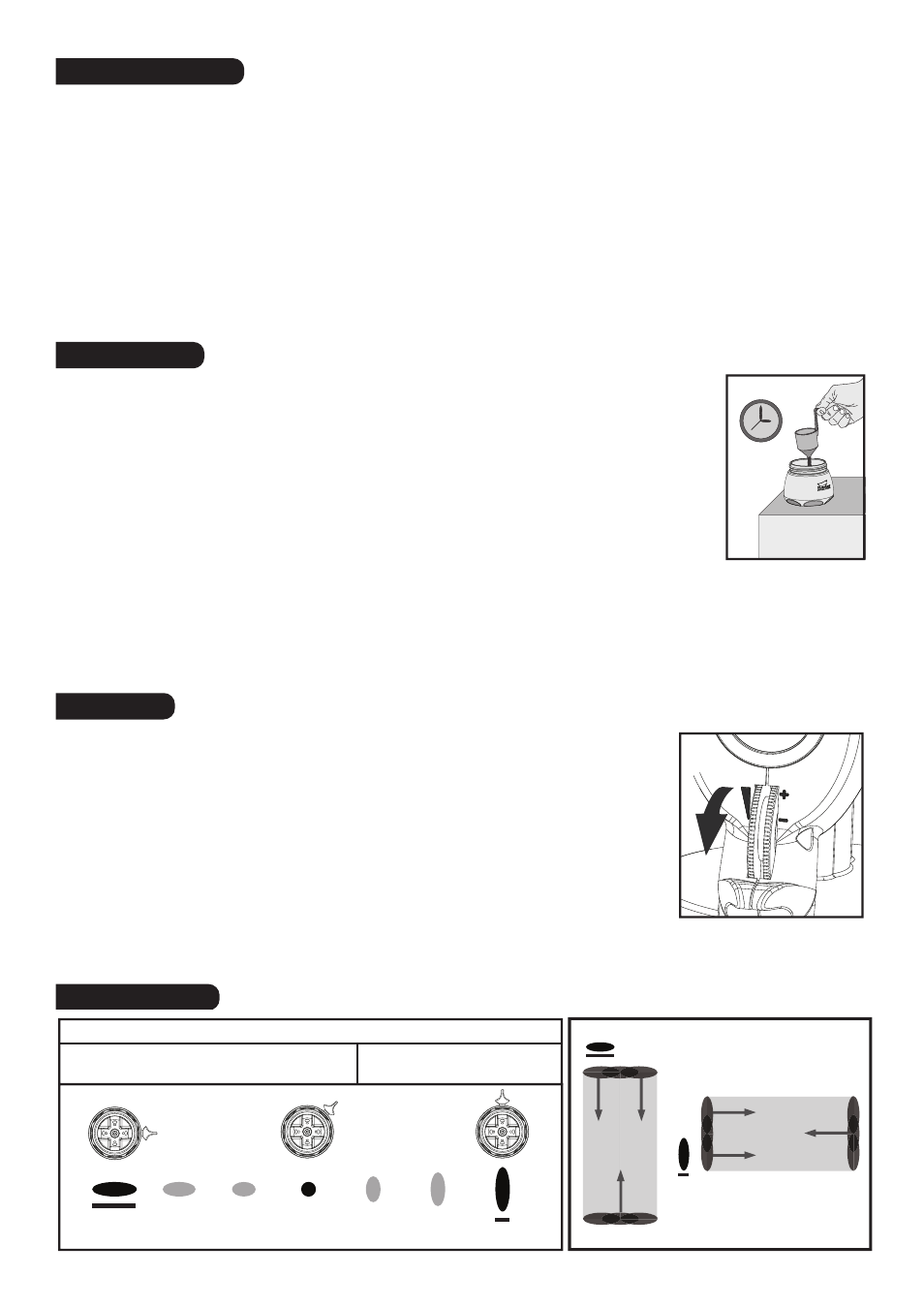

3 Spray Patterns

Horizontal and Vertical Spray with varying widths Round Spray

Vertical and Horizontal for normal sized jobs Round for small and precise jobs

Fig.6

Fig.7

Fig.5

PREPARATION

• Carefully cover areas which are not to be painted with a plastic cover and protective tape.

• Wear a suitable mask when spraying products (and make sure there is adequate ventilation in the room when working indoors).

• Clean the surface you are going to paint. As well as being clean, it must also be dry and smooth.

• Practice first on some old wooden planks to make sure you are holding the Spray Gun correctly.

• We recommend you wear protective clothing.

• Stir the paint well using a mixer where possible.

• Make sure there are no solid particles in the paint.

• Many products can be sprayed without being thinned. However, if the application is not good, thin the product progressively in stages of 5%.

• Most paints can be sprayed by being thinned just a little, e.g. by 5% or 10%.

• Some thick paints such as outer wall paints and certain undercoats will need to be thinned by 20% or 25%.

• Use water to thin a water-based product.

• Use appropriate thinner to thin solvent-based products.

• Certain manufacturers will indicate on the can whether a specific thinner is to be used.

• Certain paint manufacturers have specific paints available for HVLP application.

Dip the viscosity cup into the material and fill up. Check the guide below for the viscosity rating for your machines. Time

how long it takes for the paint to stop being a continuous flow, from the bottom of the cup (Fig.4). If the paint requires

thinning, start with a 5% dilution of the paint. To do this, part fill a container with one litre of paint. The viscosity cup

supplied with the unit holds 1/10 of a litre, block the hole in the viscosity cup and fill up with the required thinner. Add the

thinner to the paint and stir, measure the viscosity. If the paint requires further thinning, dilute the paint by another 5%

(5% will be equal to half a viscosity cup) with the required thinner and measure the viscosity, if the paint is not at its

recommended viscosity, repeat the above step.

Viscosity Ratings

The spray station 2900/3500 has a viscosity rating of 160 seconds. If the paint has emptied the viscosity cup in less

than 160 seconds then you will not need to thin your paint or material. If it is above this then thinning will be required.

The spray station 3900 has a viscosity rating of 180 seconds. If the paint has emptied the viscosity cup in less than

180 seconds then you will not need to thin your paint or material. If it is above this then thinning will be required.

The spray pack has a viscosity rating of 70 seconds. If the paint has emptied the viscosity cup in less than 70

seconds then you will not need to thin your paint or material. If it is above this then thinning will be required.

The above ratings are a guide, dependent on paint formulation further dilution may be required in increments of 5%.

12

3

1

2

4

5

6

7

8

9

10

11

DILUTION

Fig.4