Listing and code approvals, Performance summary table – England's Stove Works 60-SHBVNG User Manual

Page 4

LISTING AND CODE APPROVALS

THIS VENTED GAS FIREPLACE HEATER HAS BEEN TESTED FOR COMPLIANCE WITH THE ANSI

STANDARD Z21.88-2002 AND THE CANADIAN CSA 2.33-M02 STANDARDS. THIS UNIT IS LISTED

WITH INTERTEK TESTING SERVICES (WARNOCK HERSEY, INC.) OF MIDDLETON, WISCONSIN. ALL

COMPONENTS ARE AGA, CGA, UL OR CSA APPROVED.

THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH LOCAL CODES, IF ANY; IF NOT,

FOLLOW ANSI Z223.1 (NFPA 54), CURRENT EDITION IN THE U.S. OR CAN1-B149, CURRENT EDITION

INSTALLATION CODE IN CANADA.

NOTE: SEE LABEL ON THE VALVE FOR GAS PRESSURE TESTING LOCATION.

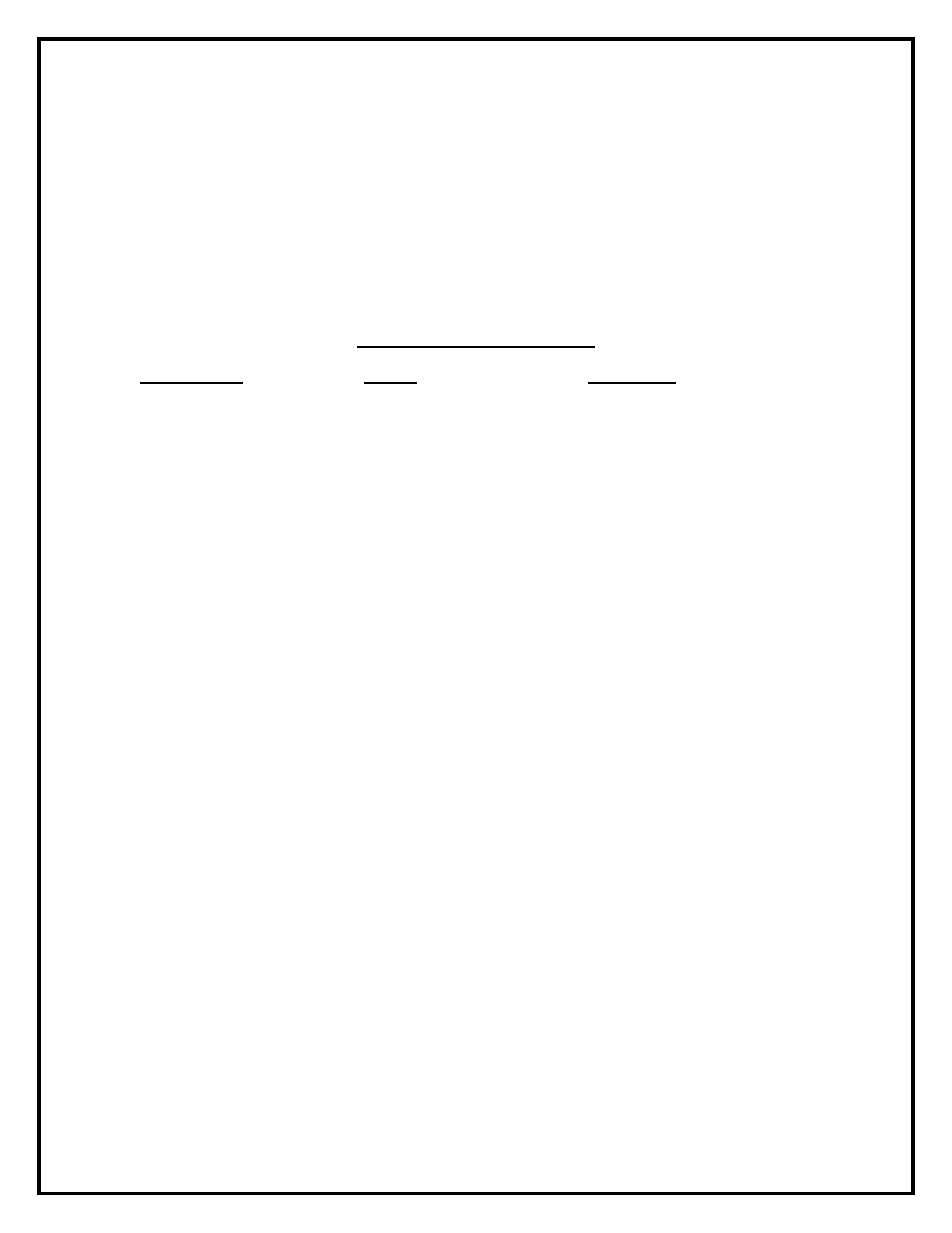

Performance Summary Table

Characteristic

LP Gas

Natural Gas

Fuel

requirement LP

Gas

Natural

Gas

Input rating (0-610m)

33,200

BTU/HR

32,000

BTU/HR

Minimum input (0-610m)

18,600 BTU/HR

22,500 BTU/HR

Input rating (610 – 1370m)

30,200

BTU/HR

29,300

BTU/HR

Orifice

size

(0-610m)

#51

DMS

#33

DMS

Max. inlet pressure

13.5” W.C. (3.36 kPa)

10.5” W.C. (2.61 kPa)

Min. inlet pressure

11.0” W.C. (2.74 kPa)

4.5” W.C. (1.12 kPa)

Max. manifold pressure

10.0” W.C. (2.49 kPa)

3.5” W.C. (0.87 kPa)

Min. manifold pressure

3.7” W.C. (0.92 kPa)

0.9” W.C. (0.22 kPa)

Max.

efficiency,

with

fan

81.7%

77.9%

Max. output (0-610m)

27,300

BTU/HR

25,400

BTU/HR

Gas consumption (std. cond.)

13.3 Cu. Ft/hr or 0.4 gal/hr.

32 Cu. Ft/hr

Fuel supply line

½ inch (13 mm)

½ inch (13mm)

Flue exit

4” Diameter (Top or Rear)

4” Diameter (Top or Rear)

Chimney spec.

Type B-1 (4” Dia.)

Type B-1 (4” Dia.)

Ignition

Piezo electric & pilot

Piezo electric & pilot

Actual

weight

161

lbs.

161

lbs.

Shipping

weight

185

lbs.

185

lbs.

SECTION I: FLUE SYSTEM FOR VENTED GAS FIREPLACE HEATER

A. Installation of a New System (See Installation Drawings at the end of this Manual)

This vented gas fireplace heater must be connected to four-inch (4”) diameter Type B-1 gas

pipe. This product is manufactured and certified to NFPA 54 and NFPA 211 “current edition”

standards. The minimum clearance of this pipe to combustible materials is one inch (1”). Never

use aluminum or galvanized steel pipe with this unit.

Single wall pipe may be used between the stove and ceiling or stove and wall; a minimum of

six inches (6”) clearance to combustible materials is required for this type of pipe. It is imperative

that the single wall pipe be terminated at the ceiling or wall, by connecting to a double wall B-1

Vent Pipe. Single wall pipe should never pass through a combustible wall or ceiling. Follow the

pipe manufacturer’s instructions for venting through a combustible area.

Installation requirements for single wall pipe or Type B-1 Vent Pipe are specified in the ANSI

Z223.1 or CAN1-B149 Standard “current edition.” These standards will also indicate proper

clearances to combustibles. Your stove dealer or qualified service person will be familiar with

these standards and can properly install the chimney system.

Connection of the pipe to the stove is accomplished by placing the pipe over the collar on the

top or rear of the unit; then secure the connection with a screw through the pipe.