Problem cause action required, Troubleshooting periodic maintenance turbine unit – Earlex hv5500 User Manual

Page 8

8

Questions? Call toll free: 888-783-2612

The turbine unit only requires minimal maintenance

●

Ensure its filter (28) element is kept clean at all times.

This is the filter underneath the main body of the turbine. Disconnect the unit from the power supply, turn on side and remove foam material. This

can be washed out if necessary and replaced when dry. From time to time this filter will need replacing (part no.L0058).

●

The turbine bearings are sealed and lubricated for life. There is no maintenance or adjustment required.

●

Clean the turbine and hose unit with a damp cloth after use.

●

The hose is stowed by coiling it between the motor housing and hose cover.

●

The power cord is stowed by wrapping around the base of the unit and locating the plug in the space at the back of the unit.

Gland washers (16) prevent leakage of air passing the needle. This leakage reduces the performance of the spray gun and must, therefore, be kept

to a minimum. After a period of use the gland washers will wear. This is normal and can be compensated by gradual adjustment of the gland nut (15).

Periodically check to ensure the gland nut is not loose. DO NOT OVER-TIGHTEN as this will increase wear of the washers. When necessary just

tighten the nut lightly using the special spanner (27) provided.

By tightening this nut, the inside diameter of gland washers reduce thereby closing any small gap that may have occurred between the needle and

gland washers, therefore, eliminating excessive leakage.

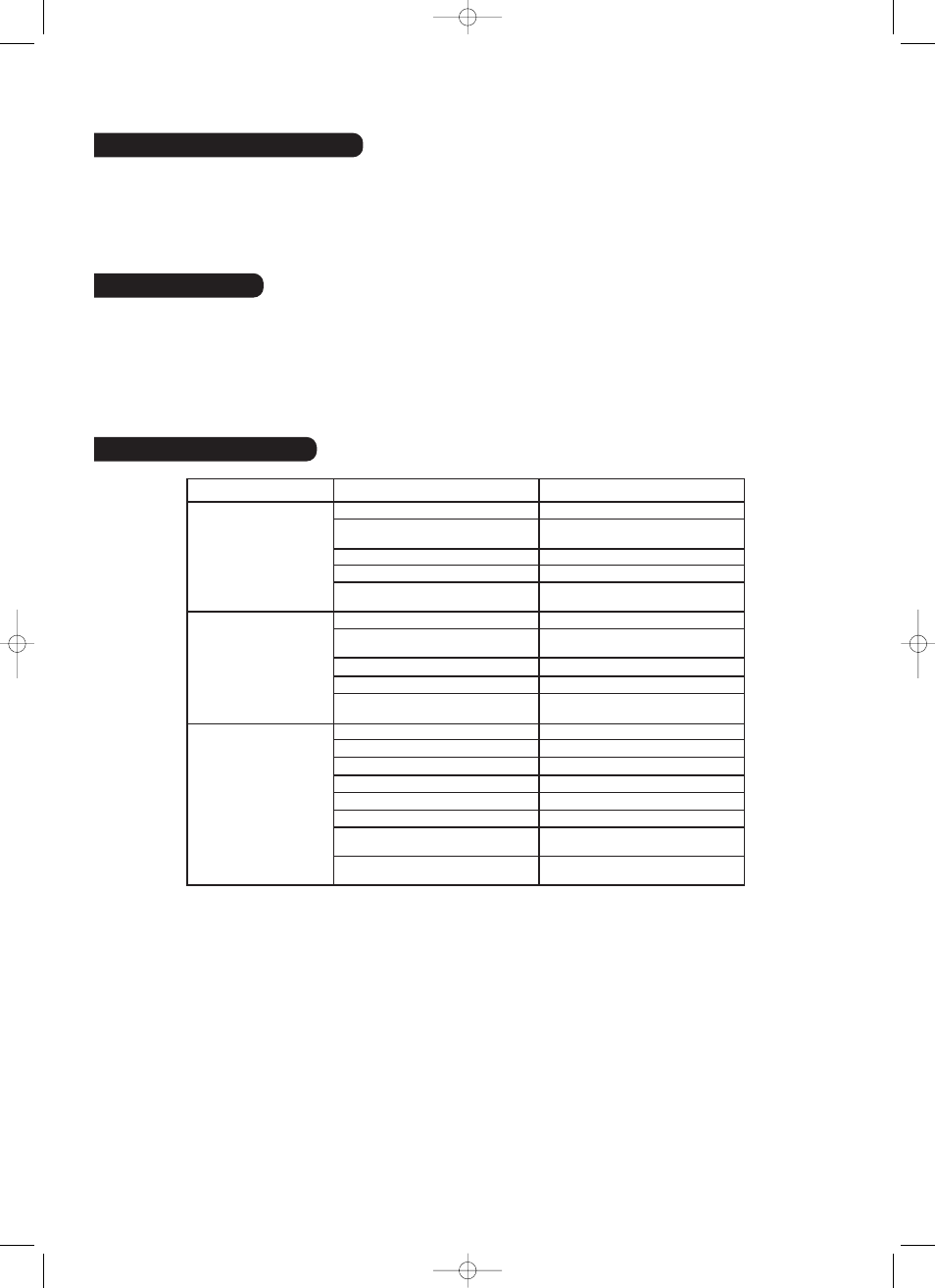

PROBLEM

CAUSE

ACTION REQUIRED

The paint runs on the item

being sprayed

Paint too diluted

Add undiluted material

Paint volume too high

Reduce the paint flow by adjusting

screw (12)

Moving too slowly

Increase speed of application

Gun trigger being held for too long

Release trigger earlier

Gun too close

Increase the distance between gun and

workpiece

Paint is thin or irregular

Paint too diluted

Add undiluted material

Paint volume too low

Increase the paint flow by adjusting

screw (12)

Moving too fast

Reduce speed of application

Gun clogged

Clean the gun

Gun too far away

Reduce the distance between gun and

workpiece

No paint being produced

Paint too thick

Add thinner

Gun clogged

Clean the gun

Pick up tube clogged

Clean pick up tube (24)

Air hose split

Replace air hose

Grainy paint

Filter the paint

Container almost empty

Refill container

Gun at an angle

Ensure pick up tube is angled towards

paint

Air intake blocked

Check no paper or loose debris can

block the air intake underneath the unit

TROUBLESHOOTING

PERIODIC MAINTENANCE

TURBINE UNIT

L1325_5500_0311.qxd:Layout 2 7/3/11 17:00 Page 8