Maintenance, Bleed-off, Spring start-up – Essick Air AUA5112 User Manual

Page 3: Amperage draw and belt tension, Caution, Warning, Fig. 10, Fig. 9, Fig. 7, Fig. 8

3

110498-2

will protect you from someone turning on

unit while you are working inside. This

should be done for your safety. Adjust

pulley to a larger diameter and readjust belt

tension, plug motor in, install inspection

panels, and retest amperage draw. Repeat

this process until correct amperage draw is

attained. Increasing motor pulley diameter

increases amperage draw. Decreasing motor pulley diameter decreases

amperage draw (see Fig. 9).

CAUTION:

Do not operate cooler with larger amperage draw

than specifi ed on motor plate.

NOTE: No attempt should be made to completely install this unit

without the aid of an electrician or someone familiar with testing

amperage draw. Failure to comply with these instructions may void

your warranty.

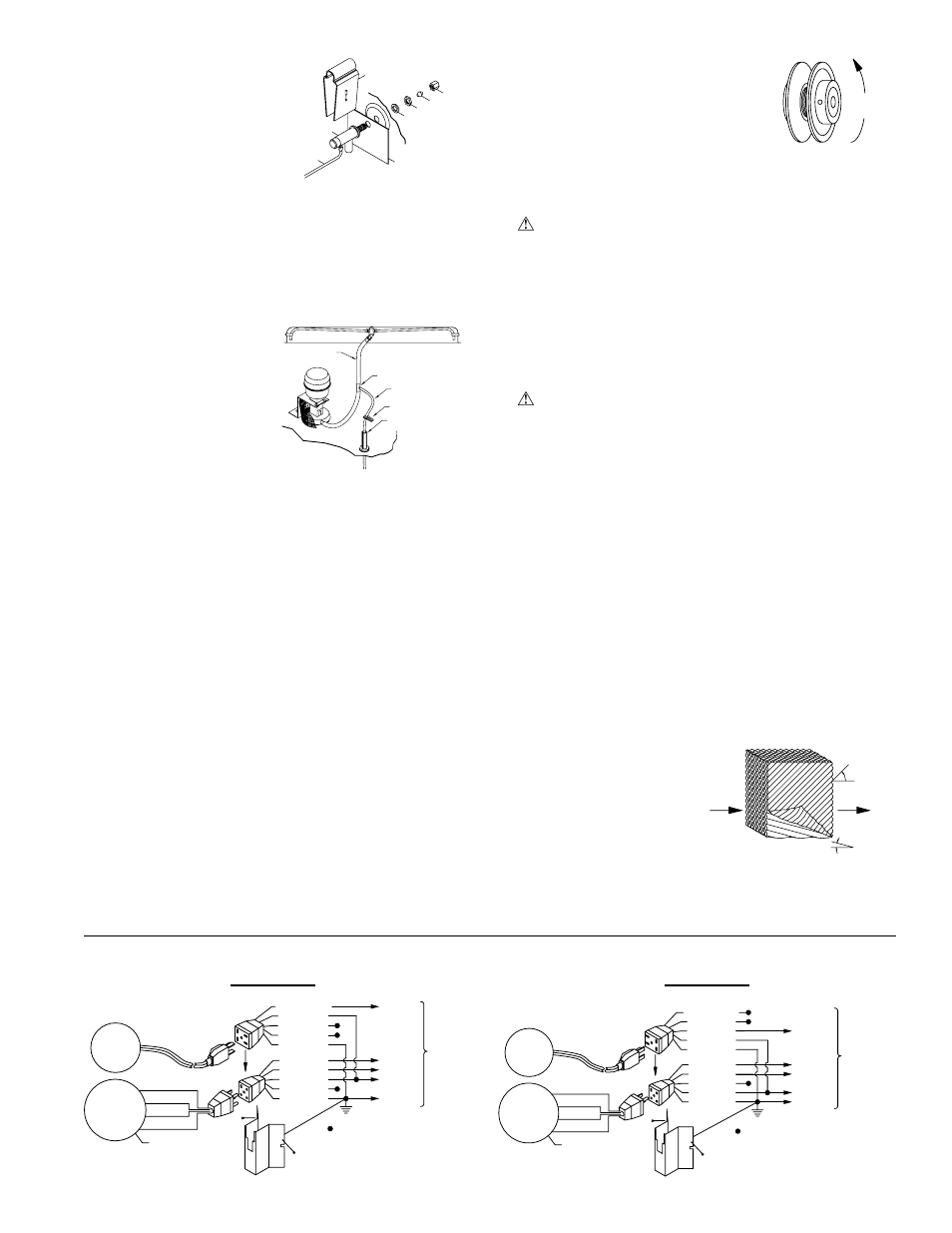

Bleed-Off

Installation of the bleed-off kit is recommended to increase the life of

the cooler. A bleed-off system is designed to prevent scale build up by

continually removing a small percent of the water in the pan.

• Install Bleeder Tee and Tub-

ing. Refer to fi gure 8. Cut the

pump hose and insert the barbed

ends of the bleeder tee into each

cut end. Insert one end of the

bleeder tubing onto the bleeder

tee and run the other end out of

the cooler through the overfl ow

pipe. Note: A restrictor clamp is

provided which, if desired, may be installed onto the bleeder tubing

to restrict the amount of water being bleed off. The amount of water

to bleed off depends on the quality of the water in your area. Start

with 1-2 gal/hr and increase if needed.

ASA35 only) and back post panel as

shown. Install washer (1) and nut (2).

Tighten to keep fl oat from turning.

Place nut (4) and ferrule (3) on water

supply line. Connect to fl oat fi tting

and tighten until water tight. Bend

rod (6) to adjust fl oat until water level

is about 1 inch below the top of the

overfl ow pipe. Slide fl oat shield (7)

over fl oat body (5) until it snaps into

place.

Com.

To Switch

Pump

Motor

Blower Motor

Red

Orange

Green

Black

Ground

Com.

Lo

Hi

= Wire Nut

Ground

Lo

Hi

Pump

Black

Red

White

Orange

Green

Green

Orange

Brown

White

Blue/Black

Blue/Black

White

Brown

Orange

Green

Green

Orange

White

Red

Black

Pump

Hi

Lo

Com.

Ground

= Wire Nut

Hi

Lo

Com.

Ground

Black

Green

White

Red

Blower Motor

Pump

Motor

To Switch

Maintenance

WARNING :

Before doing any maintenance be sure power

is off. At the time you remove either inspection panel be sure to

unplug motor and pump. This is for your safety.

Spring Start-Up

• Clean pads. A clean pad is more absorbent, effi cient and will give

more cool air. Annually, or when required, using a garden hose with

nozzle, back wash to clean out the openings, then clean off the inlet

face any scale or other obstruction to the passages. Slight scraping

may be required to remove hardened scale.

• Change pads if necessary. The pads should be replaced after 5 years

or if necessary. To change pads, remove top access panel, remove

grill, and disconnect water delivery tube. Remove water distributor

holder and lift out media sections. Replace with the same type media.

You can purchase them from your dealer.

IMPORTANT: In order to get the best performance from your cool-

ing pads, they must be installed properly. If you have purchased a pad

with two equal angles, the following instructions can be disregarded.

Pads must always be installed with the steeper fl ute angle sloping down

towards the air entering

side (Fig. 10). The reason

is simple. The steeper

angle puts more water on

the hot, dry, dirty side of

the pad where it is needed

most. It also counteracts

the tendency of the air to

push the water toward the

back of the pad.

Amperage Draw And Belt Tension

This unit is equipped with an adjustable motor drive pulley for adjusting

the blower wheel speed to the proper loading on different duct systems.

It is important that the motor drive pulley is adjusted to correct size to

assure maximum air delivery without damage to the motor. Be sure to

follow these instructions carefully.

• Adjust drive pulley. After the unit is completely installed, adjust

the drive pulley to the least diameter and adjust belt tension. See the

maintenance section for adjusting belt tension.

• Start cooler. Install both inspection panels, start pump, and allow to

operate until pads are wet.

• Check amperage. With pads wet and unit started, check amperage

draw with an amperage meter.

• Adjust pulley if necessary. If amperage draw is less than motor rat-

ing, turn off electrical power and remove inspection panels (top pan

for models ADA35 and ASA35). Unplug motor inside cooler, this

45°

15°

Entering

Air

Leaving Air

Fig. 10

Wiring Diagrams

120 Volts

240 Volts

Decrease

Amperage

Fig. 9

1

2

3

4

5

6

7

Fig. 7

8 (ADA/

ASA35)

Restrictor

Overfl ow

Bleeder Tubing

Bleeder Tee

Pump Hose

Fig. 8