Epson DW621 User Manual

Page 5

2

SERVICE

•

Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

•

When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

Additional Safety Rules

•

Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or

its own cord. Contact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

•

Keep handles dry, clean, free from oil and grease. It is

recommended to use rubber gloves. This will enable better control

of the tool.

•

The label on your tool may include the following symbols.

• The label on your tool may include the following symbols.

V ............................volts

A ............................amperes

Hz ..........................hertz

W ..........................watts

min ........................minutes

..........................alternating current

......................direct current

no ..........................no load speed

..........................Class II Construction

…/min ....................revolutions or reciprocation per minute

..........................earthing terminal

..........................safety alert symbol

Motor

Be sure your power supply agrees with nameplate marking.

120 AC means your tool may be operated only with alternating

current and never with direct current.

Voltage decrease of more than 10% will cause loss of power and

overheating. All tools are factory tested; if this tool does not operate,

check the power supply.

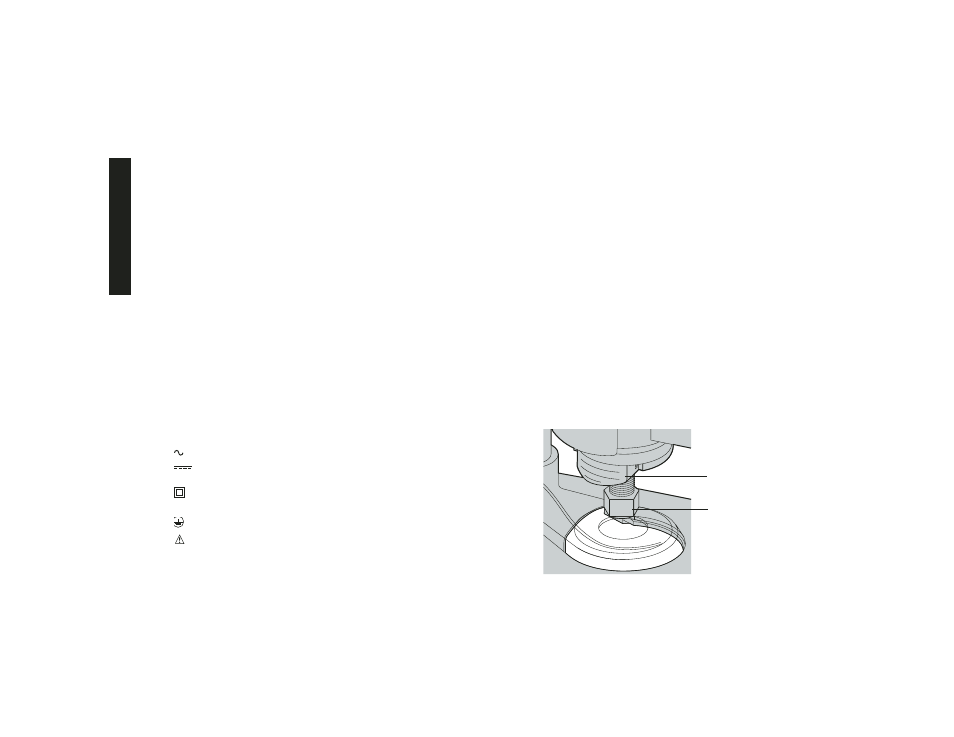

Bit Installation and Removal

TURN OFF AND UNPLUG ROUTER

NOTE: Always snap the collet firmly into the collet nut, (past the

retainer spring) before installing a bit.

Use the supplied wrench and the spindle lock as necessary to loosen

(counterclockwise) the collet nut, (Fig. 1).

Insert the round shank of the desired router bit into the loosened

collet as far as it will go and then pull it out about 1/16". Hold the

spindle shaft by depressing the spindle lock button, while firmly

tightening the collet nut with the wrench provided.

Your router has a unique locking system for retaining the bit. When

removing a bit, the collet nut must be loosened with the wrench. The

English

FIG. 1

SPINDLE LOCK

COLLET NUT