Eicon Networks Dialogic Media Board DMV600BTEC User Manual

Dialogic, Dmv600btec media board, Before you begin

Dialogic

DMV600BTEC

Media Board

Quick Install Card

Part Number 64-0079-02

Copyright © 2003-2007

Dialogic Corporation.

All Rights Reserved.

Before You Begin

Protecting the Board from Damage

CAUTION:

All computer boards are sensitive to

electrostatic discharge (“ESD”). Handle all static-

sensitive boards and components at a static-safe

work area, and observe anti-static precautions at all

times.

If you are not familiar with ESD safety precautions,

more.

Unpacking the Board

Unpack the Dialogic

®

DMV600BTEC Media Board

(“board”) according to the following steps:

1. Prepare a static-safeguarded work area.

2. Carefully remove the board from the shipping

carton and anti-static packaging. Handle the

board by the edges and avoid touching the

board’s components.

3. Lay the board on the static-dissipative work

surface.

Note: Place boards in static-shielding bags when

carrying boards from station to station.

CAUTION: Do not remove the board from the anti-

static packaging until you are ready to install it.

Observe proper anti-static precautions at all times.

Installing the Hardware

Note: For a new installation, you should install the

hardware before installing the system software. If you

are adding boards to an existing system, there is no

need to uninstall or reinstall the software.

CAUTION: This document provides instructions for

installing the DMV600BTEC in a “cold” (power off)

system, most of which also apply to live insertion or

hot swap systems. It is important to note that there

are additional, system-dependent considerations for

live insertion. See the Administration Guide for your

Dialogic

®

System Software release for detailed

information on live insertion.

1. Work at a static-safe area. Turn the power to the

chassis OFF if you do not have a live insertion

system. If you have live insertion capability, the

power to the chassis can remain ON.

2. Remove the chassis cover plate or open the door

on both the front and back of the chassis.

3. Select an empty slot and remove the slot’s access

cover plates (if applicable).

Installing the Rear I/O Module

Note: If you are installing hardware in a live insertion

system with the power on, you should install the rear

I/O module before the baseboard.

4.

Install the I/O module in the rear of the selected

slot. Use the slot’s board guides as you insert the

board into the chassis slot. Make sure the tabs on

the board extractors engage the guide holes in the

chassis card cage, then lock down the board

extractors until the red locking tabs snap shut.

CAUTION: CompactPCI backplane pins are easily

bent. Make sure that the board connectors are

mating properly with hand pressure before fully

seating the board. When using the board extractors

to seat the board, make sure to seat evenly.

CompactPCI

Chassis (Rear)

Installing Rear I/O Module

Locked

Position

Unlocked

Position

Bac

kplane

Rear I/O

Module

Installing the Baseboard

Note: If you are installing hardware in a live insertion

system with the power on, you should install the rear

I/O module before the baseboard.

5. Install the baseboard in the front of the selected

slot. Use the slot’s board guides as you insert the

board into the chassis slot. Make sure the tabs on

the board extractors engage the guide holes in the

chassis card cage, then lock down the board

extractors until the red locking tabs snap shut.

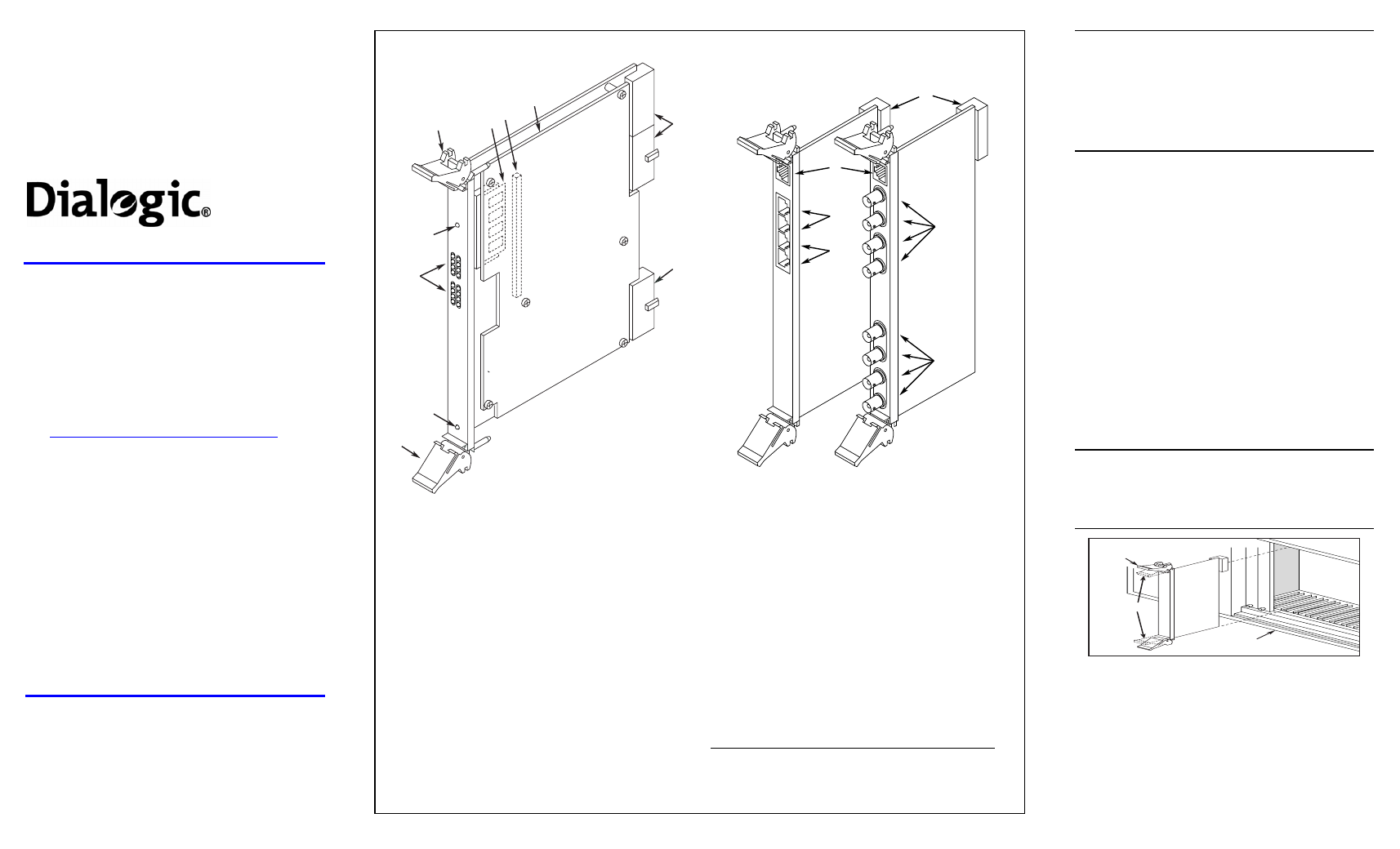

Physical Description

1

2

3

4

5

6

8

8

7

RE

D

YE

L

RE

D

YE

L

CA

RR

SG

NL

LO

OP

BA

CK

CA

RR

SG

NL

LO

OP

BA

CK

OUT O

F

SER

VIC

E

PO

W

ER

Com

pac

tP

CI

A

L

A

R

M

S

/

S

T

A

T

U

S

4

3

2

1

4

E

T

H

E

R

N

E

T

E

T

H

E

R

N

E

T

11

12

9

10

Not

Used

Not

Used

RJ48C

(T1 and 120-Ohm E1)

BNC

(75-Ohm E1)

J1

J2

R1

R2

T1

T2

CompactPCI Baseboard

Rear I/O Modules

1. Out of Service LED: Indicates board is out of service or

in reset from host.

2. Alarm/Status LEDs: During power-up, indicate Power

On Self Test (POST) status. During operation, the top

two sets of LEDs indicate status and alarms for the two

trunks (the bottom two sets of LEDs are unused):

Red–Indicates loss of clock on incoming line from

external network.

Yellow–Indicates loss of frame synchronization at far

end of external network.

Carrier Signal–Indicates board is powered up and

receiving signal from external T1 or E1 source.

Loopback–Indicates the T1 or E1 network is in loopback

mode.

3. Power LED

4. Board Extractor (with red locking tab)

5. Global Memory Module

6. Signal Processor Daughterboard connector

7. Signal Processor Daughterboard

8. J1, J4, J5: Board connector to CompactPCI backplane.

J1 key conforms to PICMG universal hot swap.

9. BNC Connectors (T1, R1, T2, R2,): Connectors to

external 75-Ohm E1 digital telephone network interfaces.

(Connectors T3, R3, T4, and R4 are not used in this

assembly.)

10. RJ48C Connectors (J1, J2): Connectors to external T1

or 120-Ohm E1 digital telephone network interfaces.

(Connectors J3 and J4 are not used in this assembly.)

11. Ethernet Connector: The Ethernet connectors are not

functional on this assembly.

12. J5: Rear I/O module connector to CompactPCI

backplane.

The default configuration of the Rear I/O Modules provides

loopback connection (signals to the board are looped back to

the source) when the board is powered off and during board

initialization. To disable loopback mode on either trunk,

remove the shunts from the indicated jumper pins:

RJ48C I/O module

BNC I/O module

Trunk 1

JP1 & JP2

JP100 & JP101

Trunk 2

JP3 & JP4

JP200 & JP201