Maintenance, Pulley and belt adjustments, Spring start-up – Essick Air SAD10012 User Manual

Page 3: Winter shut down

110526

3

keep fl oat from turning. Place nut

(4) and ferrule (3) on water supply

line. Connect to fl oat fi tting and

tighten until water tight. Turn on

water supply and check for leaks.

Loosen screw (6) and adjust rod

(7) until water level is within 1” of

top of reservoir. Tighten screw (6).

Slide fl oat shield (8) over fl oat body

(5) until it snaps into place.

• Bleed-Off. Use of the bleed-off kit is recommended to prevent scale

build up by bleeding off small amounts of circulating water during

operation. Do not add any type of water treatment chemicals to the

water since they may damage the evaporative media.

Pulley And Belt Adjustments

• Pulley adjustment. With an ammeter, check the motor amperage.

Adjust the pulley until the amperage draw on the motor is just below

that specifi ed on the motor nameplate. To

adjust the pulley, loosen the adjustment

set screw and rotate the sheave. Tighten

the set screw so that it is over a fl at area,

otherwise thread damage will occur. To

increase amperage draw, increase pulley

diameter. To decrease amperage draw,

decrease pulley diameter (see Fig. 6).

Recheck belt alignment.

CAUTION: Always check the amperage of the motor after ad-

justing pulley to be certain it does not exceed the amperage stamped

on the motor specifi cation plate. Improper pulley adjustment will

overload and burn out the motor.

• Belt tension. Loosen the motor mount

bolts and slide the motor back until the

belt is properly tensioned. A 3 lb. force

should defl ect the belt 3/4 inches (see

Fig. 7). Retighten motor mount bolts.

Do not adjust pulley to tighten belt.

Maintenance

WARNING: Before doing any maintenance be sure to disconnect

from power source. This is for your safety.

Spring Start-Up

• Belt tension. Check belt tension and readjust if needed.

• Grease bearings. The blower bearings in this unit should be greased

once a year with a good grade of ball bearing grease.

• Cleaning pads. A clean pad is more absorbent, effi cient and will give

more cool air. Annually, or when required, using a garden hose with

nozzle, back wash to clean out the openings, then clean off the inlet

face any scale or other obstruction to the passages. Slight scraping

may be required to remove hardened scale.

• Pad replacement. The pads should be replaced after 5 years or if

necessary. To change pads, remove top access panel, remove grill,

and disconnect water delivery tube. Remove water distributor holder

and lift out media sections. Replace with the same type media. You

can purchase them from your dealer.

IMPORTANT: In order to get the best performance from your cool-

ing pads, they must be installed properly. If you have purchased a pad

with two equal angles, the following instructions can be disregarded.

Pads must always be installed with the steeper fl ute angle sloping

down towards the air enter-

ing side (Fig. 8). The rea-

son is simple. The steeper

angle puts more water on

the hot, dry, dirty side of

the pad where it is needed

most. It also counteracts

the tendency of the air to

push the water toward the

back of the pad.

• Cleaning pump. Cleaning the pump is necessary once a year at start-

up. For your safety, disconnect from power source and unplug pump.

Remove the pump from the mount bracket. Remove the base of the

pump (Fig. 9). Clean the pump and turn the impeller to ensure free

operation. Remove the pump spout and check for any blockage. After

cleaning, reinstall the base onto

the pump. Reattach the pump to

the mount in the cooler to ensure

that the pump will not overturn.

Do not forget to replace the spout

and water delivery tube onto the

pump outlet. The pump has au-

tomatic reset thermal protection.

Pump will operate normal again

after obstruction is cleared.

• Bleed off. Check bleed-off valve to be sure it is not clogged.

Winter Shut Down

• Drain water. Always drain all of the water out of the cooler and water

supply line when not in use for prolonged periods, and particularly at

the end of the season. Keep the water line disconnected from both

the unit and water supply so that it does not freeze.

• Disconnect from power supply when not in use for extended

periods of time.

• Cover unit. To protect the life of the fi nish, a cover for the unit is

suggested in extended periods of non use.

By following the operating, installation, and maintenance suggestions

as outlined, you can get many years of effi cient and satisfactory service

from your cooler. In the event additional information is desired, your

dealer will be more than glad to assist you in every possible way.

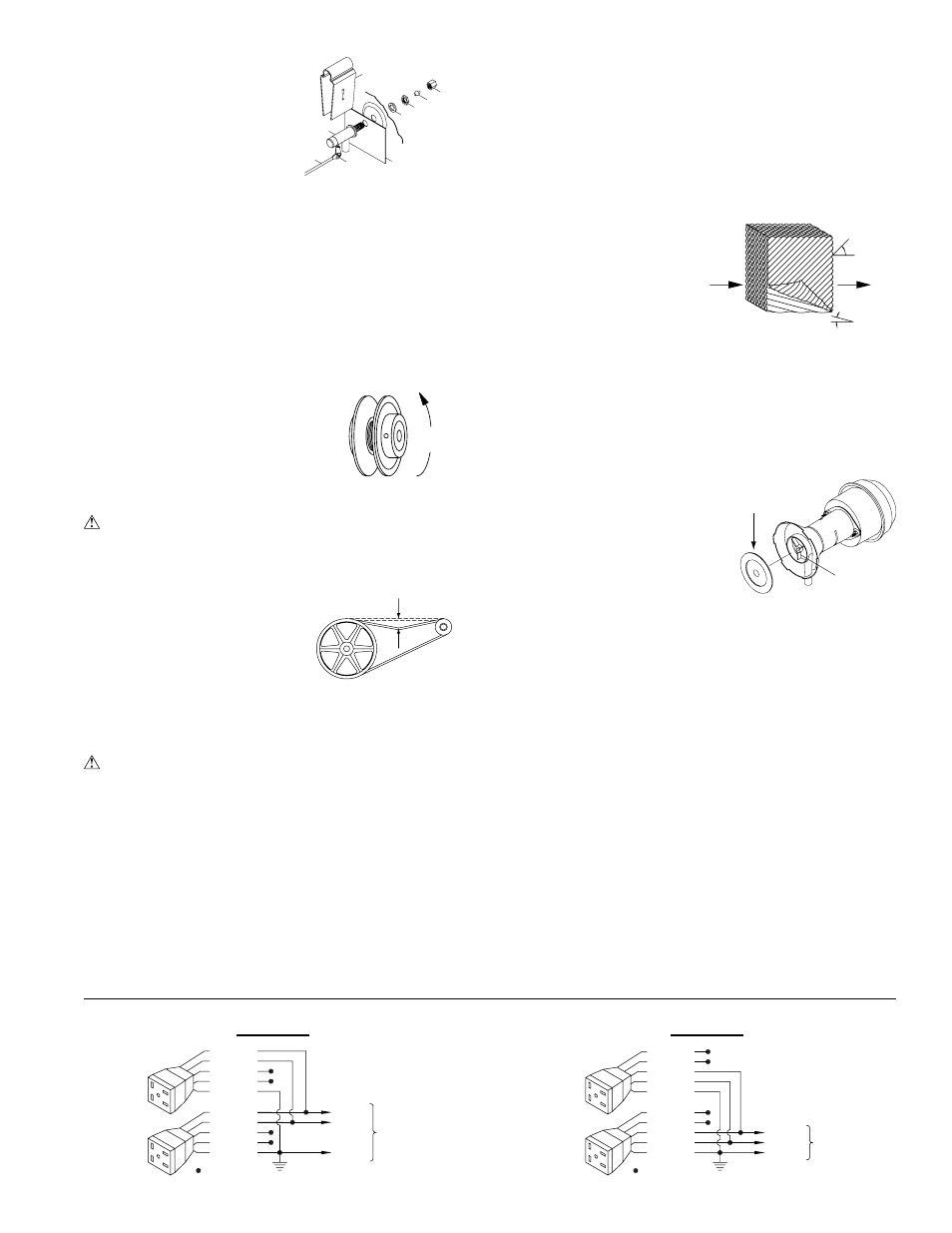

Ground

Blue/Black

White

Brown

= Wire Nut

Orange

Green

Green

Orange

Brown

White

Blue/Black

Pump

Com.

To

Switch

Com.

Pump

Blue/Black

White

Brown

Orange

Green

Green

Orange

= Wire Nut

Brown

White

Blue/Black

Ground

To

Switch

120 Volts

240 Volts

Pump Wiring Diagrams

Decrease

Amperage

Fig. 6

45°

15°

Entering

Air

Leaving Air

Fig. 8

Impeller

Remove

Base

Fig. 9

Fig. 7

3 Lb.

3/4 Inches

1

2

3

4

5

7

8

Fig. 5

6

9