Diamond Systems 46-756 User Manual

Page 19

19

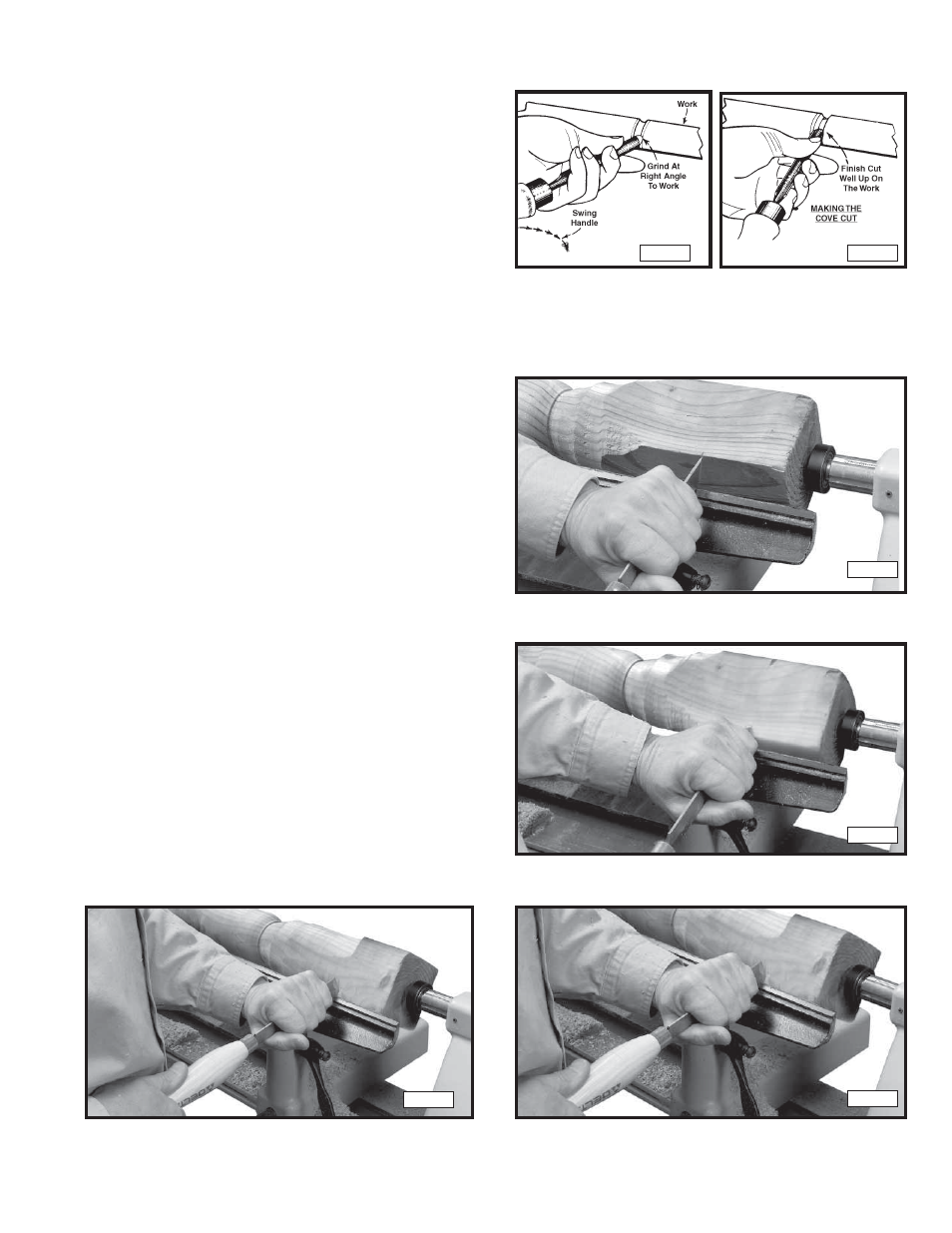

The gouge is placed on edge on the tool rest so that

the grind of the chisel forms an approximate right angle

with the work (Figs. 57). The chisel contacts the work at

the center of the cutting edge. Hold the tool so that the

centerline of the gouge is pointing directly toward the

center of the revolving stock. This starting position is

important to prevent the gouge from running along the

surface of the work.

From the starting position, push the gouge into the

revolving stock, and roll the tool on the rest. A triple

action takes place here. (1) The chisel will roll to follow

the shape of the cut, (2) the handle will drop slightly so

that the portion already cut will force the lip of the

chisel sideways and, (3) the chisel will be pushed for-

ward so that at the end of the cut, Fig. 58, it will be well

up on the work and tangent with the cut surface. Make

only one-half of the cut at a time, then reverse the chisel

to cut the other half. The occasional turner should make

cove cuts with a scraping technique, using either the

small gouge or round nose chisel.

SQUARE SECTIONS

When the turning has a square section, joint the stock

before turning. Good centering is essential since any

error will show at the shoulder where the round meets

the square. Turning of the shoulder from square to

round can be done in various ways. If the parting tool

is sharp, the nicking cut with skew (Fig. 59) can be

omitted. The final trimming operation (Fig. 62) can be

done with either the skew, spear chisel, or gouge, and

is a scraping operation. While the shoulder can be cut

with the same technique used for cutting a bead, the

simpler scraping method pictured does clean work and

is easier to do.

Fig. 57

Fig. 58

Fig. 59

Fig. 60

Fig. 61

Fig. 62