Operation, Lathe tools, How to turn spindles – Diamond Systems 46-756 User Manual

Page 13: Centering the work

13

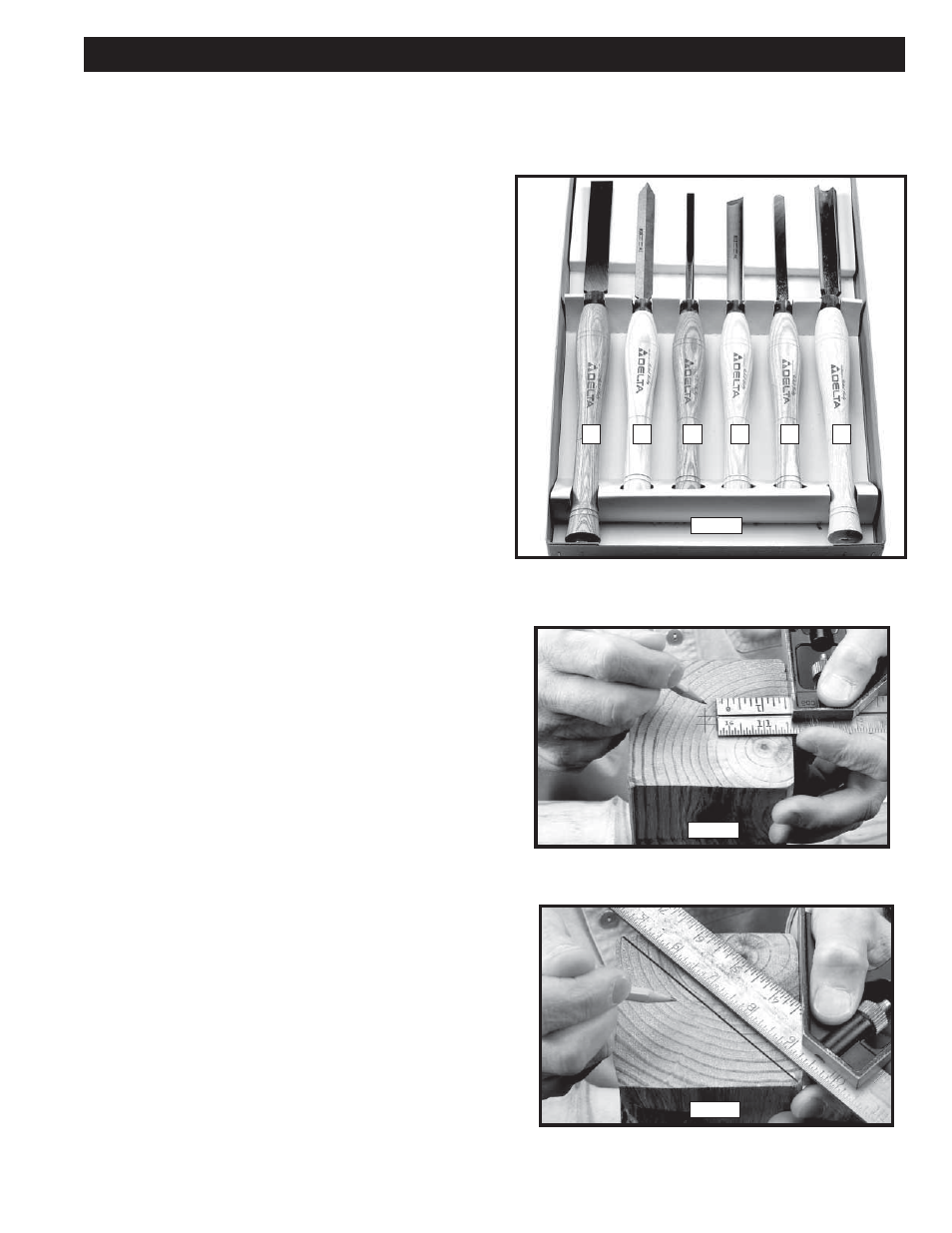

LATHE TOOLS

Standard wood turning tools come in several different

configurations (Fig. 26). The majority of turnings will

require the gouge tool (A) Fig. 26. This round nosed

hollow chisel is used for roughing cuts, cove cuts and

other operations. The skew chisel (B) is a double-ground

flat chisel, with an angled end. This tool is used for

smoothing cylinders, for cutting shoulders, beads, vee-

grooves, etc. The parting tool (C) is a double-ground

chisel, used for cutting-off, or for making straight

incisions or sizing cuts to any required diameter. The

round nose scraper (D) is used for mostly hollowing

work, while the square-end scraper is mainly used for

the outside of bowls.

The following directions will give the inexperienced operator a beginning point for common lathe operations. Practice

on scrap material before attempting serious work.

HOW TO TURN SPINDLES

Working with any material that is attached to the lathe

centers is called a spindle turning. This is the principal

type of wood turning (chair and table legs, lamp stems,

etc.) The turning of spindles can be done with either a

scraping or cutting technique. The cutting technique, by

virtue of faster wood removal and a cleaner surface, is the

preferred method.

CENTERING THE WORK

Wood stock for any spindle turning should be approx-

imately square, and the ends should be square with the

sides. Two common methods of determining the center

are shown in Figs. 27 and 28. In Fig. 27, a distance a

little more or a little less than one-half the width of the

stock is set off from each of the four sides. The small

square set off in the center can then be used in marking

the true center. The diagonal method, Fig. 28, consists

of drawing lines from corner to corner, with the intersec-

tion marking the center of the work.

OPERATION

Fig. 26

Fig. 27

Fig. 28

A

B

D

A

C

E