English assembly, Chain saw names and terms, Continued – Desa 11174-01 User Manual

Page 9

7

107705

www.desatech.com

ENGLISH

ASSEMBLY

Note: Some models are pre-assembled. Assembly is

not needed on these models.

See Saw Chain Tension Adjustment, pages 8 and 9.

1. Lay chain out flat.

2. Loosen and remove guide bar nuts and sprocket

cover.

3. Loosen and remove drive sprocket screw or re-

move E-ring from shaft (see Figure 4). Remove

sprocket support.

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

IMPORTANT: Do not clamp chain saw in

vise during assembly.

Continued

Switch Linkage

This device connects switch to trig-

ger. It moves switch when you squeeze trigger.

Switch Lockout

Device that reduces accidental

starting of saw.

Trigger

Device that turns saw on and off. Squeezing

trigger turns saw on. Releasing trigger turns saw off.

Trimming (Pruning)

Process of cutting limb(s) from

a living tree.

Undercut

An upward cut from underside of log or

limb. This is done while in normal cutting position

and cutting with top of guide bar.

CHAIN SAW NAMES AND

TERMS

Continued

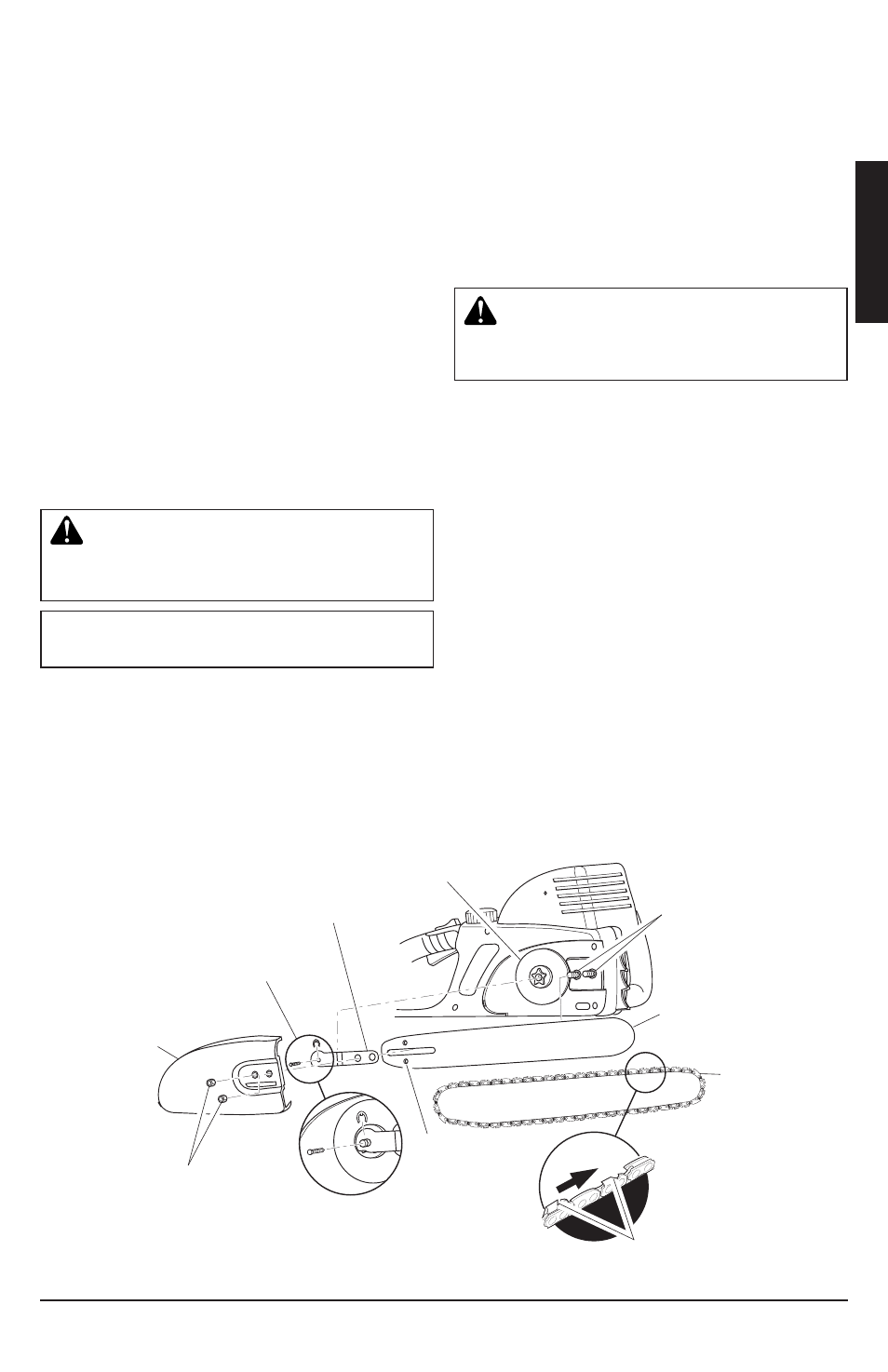

4. Install guide bar onto saw body. Assemble center

slot of guide bar onto guide bar bolts.

5. To replace sprocket support, repeat step 3 in

reverse order. Firmly tighten drive sprocket screw

with #2 Phillips screwdriver (if applicable).

6. Place chain around drive sprocket, along top

groove of guide bar, and around guide bar nose.

Note: Make sure cutting edges of chain are fac-

ing in right direction. Position chain so cutting

edges on top of guide bar face guide bar nose (see

Figure 4, and indicator on side cover of saw).

CAUTION: Do not place chain on saw

backwards. If chain is backwards, saw

will vibrate badly and will not cut.

7. Insert tab of sprocket cover into slot on side cover

and rotate sprocket cover onto guide bar bolts

until sprocket cover rests against guide bar.

8. Place guide bar nuts, removed in step 2, over

guide bar bolts.

IMPORTANT: Tighten guide bar nuts finger tight

only.

9. Turning chain tensioning knob (Model 107625-

01, -02, 111174-01) or chain tensioning screw

(Model 107624-01, -02), adjust position of

adjustment block until it is aligned and inserted

into the round adjusting hole on guide bar (see

Figure 4 and Figures 5 and 6, page 8). Turning

chain tensioning knob or chain tensioning screw

counterclockwise will move adjustment block to

rear of guide bar. Turning chain tensioning knob

or chain tensioning screw clockwise will move

adjustment block to front of guide bar.

10. If needed, readjust guide bar nuts to finger tight only.

11. Adjust saw chain tension. Follow steps under

Saw Chain Tension Adjustment,

pages 8 and 9.

Guide Bar Nuts

Sprocket Cover

Drive Sprocket Screw or E-Ring

Sprocket Support

Guide Bar Bolts

Saw Chain

Guide Bar

Drive Sprocket

Cutting Edge

Figure 4 - Assembling Guide Bar and Chain

Adjusting Hole

Towards Guide Bar Nose