Connecting machine to power source, Electrical connections single phase installation – Delta 50-851 User Manual

Page 10

10

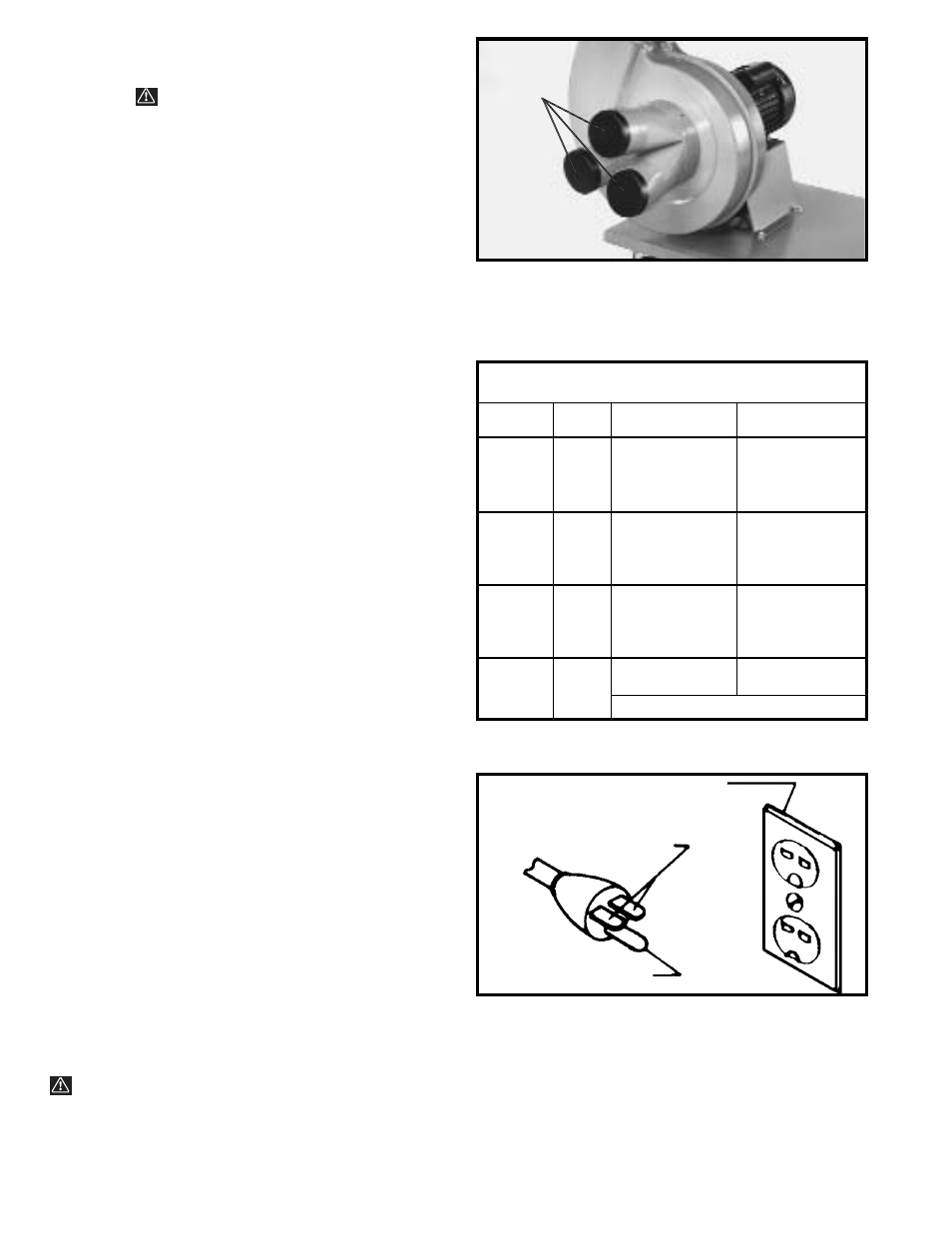

Fig. 25

3.

Three dust intake port caps (D) Fig. 25, are supplied

with the dust collector. NOTE: These caps should be

inserted into the intake ports as shown, when they are

not in use.

WARNING: DO NOT INSERT FINGERS

OR ANY FOREIGN OBJECT INTO THE DUST INTAKE

PORTS WHEN UNIT IS OPERATING.

CONNECTING MACHINE TO POWER SOURCE

ELECTRICAL CONNECTIONS

SINGLE PHASE

INSTALLATION

The motor rating of the Model 50-851 Dust Collector is

2 HP, 230 Volt, Single Phase. Before connecting your

dust collector to an electrical power system, be sure the

electrical system agrees with the motor rating of the

tool.

The power cord is equipped with a plug that has two flat,

current-carrying prongs in tandem and one round or “U”

shaped, longer ground prong. This is used only with the

proper mating 3-conductor grounding type receptacle

as shown in Fig. 26.

When the 230 Volt three-prong plug on your machine is

plugged into a grounded 3-conductor receptacle, the long

ground prong on the plug contacts first so the machine

is properly grounded before electricity reaches it.

WARNING: MAKE CERTAIN THE RECEPTACLE IN

QUESTION IS PROPERLY GROUNDED. IF YOU ARE

NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK

THE RECEPTACLE.

Fig. 26

CURRENT CARRYING

PRONGS

GROUNDED OUTLET BOX

GROUND PRONG

D

A separate electrical circuit should be used for your

tools. This circuit should not be less than #12 wire and

should be protected with a 20 amp time lag fuse. Use

proper extension cords. Make sure your extension cord

is in good condition and is a 3-wire extension cord

which has a 3-prong grounding type plug and a 3-hole

receptacle which will accept the tool’s plug. When using

an extension cord, be sure to use one heavy enough to

carry the current of the tool. An undersized cord will

cause a drop in line voltage, resulting in loss of power

and overheating. Fig. 25A, shows the correct gauge to

use depending on the cord length. If in doubt, use the

next heavier gauge. The smaller the gauge number, the

heavier the cord. Have a certified electrician repair or

replace damaged or worn cord immediately. Before

connecting the motor to the power line, make certain the

switch is in the “OFF” position and be sure that the

electric current is of the same characteristics as

stamped on the motor nameplate. All line connections

should make good contact. Running on low voltage will

damage the motor.

Fig. 25A

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC TOOLS

Ampere

Total Length

Gauge of

Rating

Volts

of Cord in Feet

Extension Cord

0-6

240

up to 50

18 AWG

0-6

240

50-100

16 AWG

0-6

240

100-200

16 AWG

0-6

240

200-300

14 AWG

6-10

240

up to 50

18 AWG

6-10

240

50-100

16 AWG

6-10

240

100-200

14 AWG

6-10

240

200-300

12 AWG

10-12

240

up to 50

16 AWG

10-12

240

50-100

16 AWG

10-12

240

100-200

14 AWG

10-12

240

200-300

12 AWG

12-16

240

up to 50

14 AWG

12-16

240

50-100

12 AWG

12-16

240

GREATER THAN 100 FEET NOT RECOMMENDED