How do i sand glued boards, How do i sand boards wider than 18, How do i get started – Dymo 31-250 User Manual

Page 17: Tips for increasing sanding belt life

17

HOW DO I SAND GLUED BOARDS?

1. Glue the boards as flat as possible at the outset.

2. Remove excess glue from the top and bottom before it dries.

3. Use a coarse belt for initial stock removal (36 to 60 grit).

4. Run the board at different locations over the entire length of the drum to prevent glue build-up on the sanding belt.

5. After glued joints are cleaned, change the sanding belt to an 80 grit. Work your way to the finer grit until you

are satisfied with the result.

HOW DO I SAND BOARDS WIDER THAN 18"?

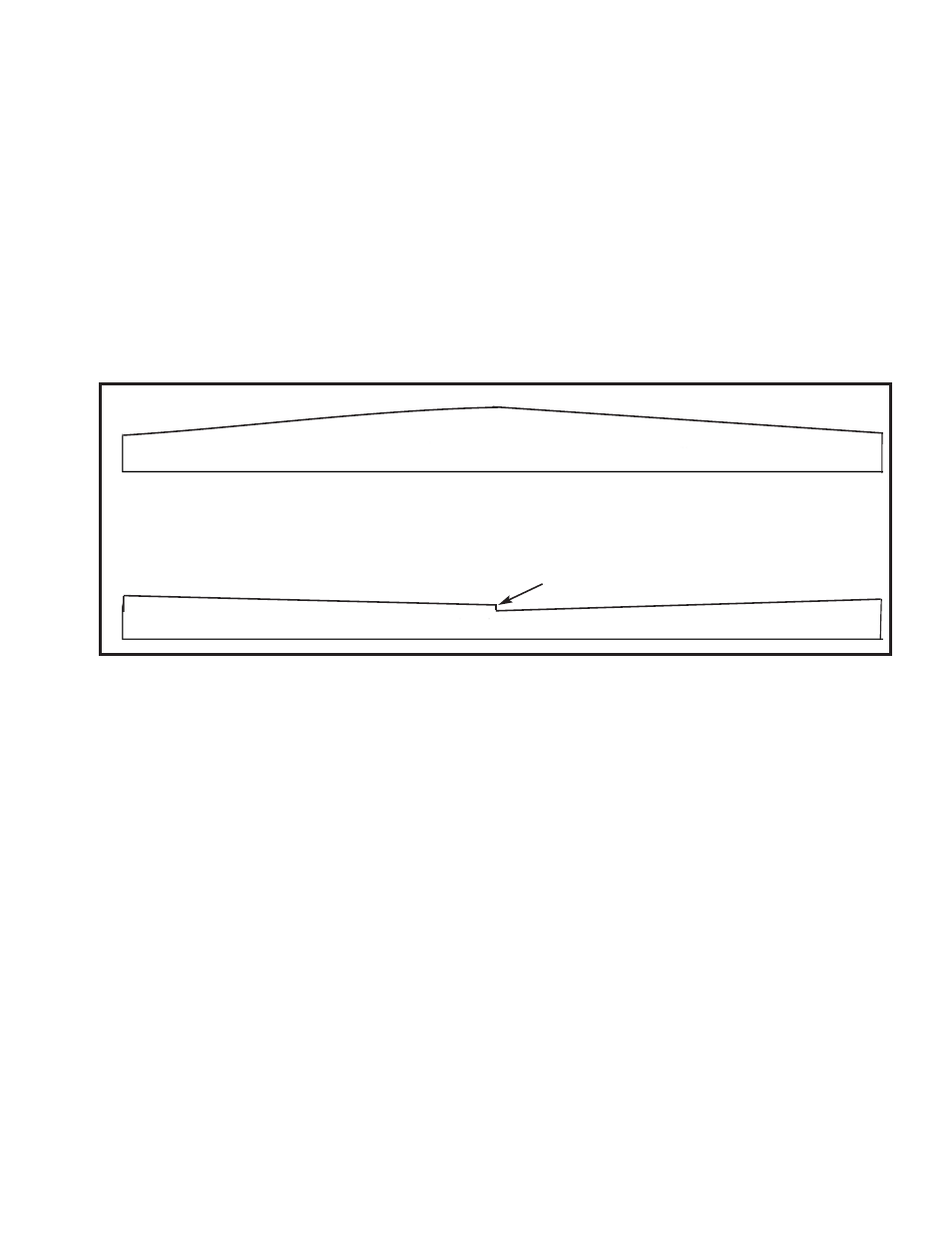

IMPORTANT: When sanding pieces wider than 18", if the drum is not parallel to the table a step or line will result. It

is best to set the open side a few thousandths of an inch more open to allow sanding a crown rather than a groove.(See

Fig. 36)

Sanding wide boards requires two separate passes. Set the table height to the board maximum thickness, and make

a pass. Then, without changing the table height, rotate the board 180 degrees and sand the other half of the board.

Adjust the table height and repeat the two sanding passes. Continue until you are satisfied with the result.

NOTE: Provide support for the part of the board that is not on the table during each pass.

Fig. 36

HOW DO I GET STARTED?

1.To gain experience, use scrap wood. Start with stock that is 2' to 4' long. These will be easier to control and to feed.

Use different wood types and different widths.

2.To see how the sander works, measure the thickness of your stock. Set the table height to that thickness and then

lower it 1/4 turn. Turn the drum switch "ON" and then turn the table feed belt speed to 50% (indicator line on the knob

vertical). If the drum does not contact the stock, raise the table height slowly while feeding the stock through, until you

see that it is sanding. Let the board feed through. Turn the handle 1/4 turn to raise the table height and make another

pass. Increase the conveyor speed as you gain confidence.

TIPS FOR INCREASING SANDING BELT LIFE:

1. When the belt becomes dull, remove and reverse the belt.

2. When the belt becomes loaded with build up, soak the belt in paint thinner or mineral spirits for 20 minutes to one

hour to loosen the build up. Then use a standard hand held wire brush and clean the belt. Allow the belt to dry

completely before using.

3. When sanding boards under 9" wide, place the board through the sander at a slight angle (60 degrees). This will

spread the sanding action out over a larger area of the drum rather than in one area. Then make the finish pass

with the grain.

4. Delta offers a full line of sanding belts, in all grit sizes, in both bulk rolls and pre-cut strips.

5. When sanding narrow boards, run them through at different locations over the entire width of the drum.

Example of exaggerated results if open end of drum is higher.

Example of exaggerated results if open end of drum is lower.

STEP