Assembly, Unpacking and cleaning, Assembly tools required – Draytek SHOPMASTER SM200L User Manual

Page 9: Assembly time estimate - 1 hour

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from all

unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone, gasoline

or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household floor paste

wax.

ASSEMBLY

ASSEMBLY TOOLS REQUIRED

(None supplied)

* Phillips head screw driver

* 13mm wrench for stand bolts

* 10mm wrench for splitter assembly bolts

* Straight edge and/or framing square for adjustments

ASSEMBLY TIME ESTIMATE - 1 hour

THE SAW MUST BE PROPERLY SECURED TO A SUPPORTING SURFACE. ALSO, FAILURE TO

PROVIDE A SAWDUST FALL-THROUGH AND REMOVAL HOLE WILL ALLOW SAWDUST TO BUILD

UP AROUND THE MOTOR, CAUSING A POSSIBLE FIRE HAZARD AND/OR MOTOR DAMAGE.

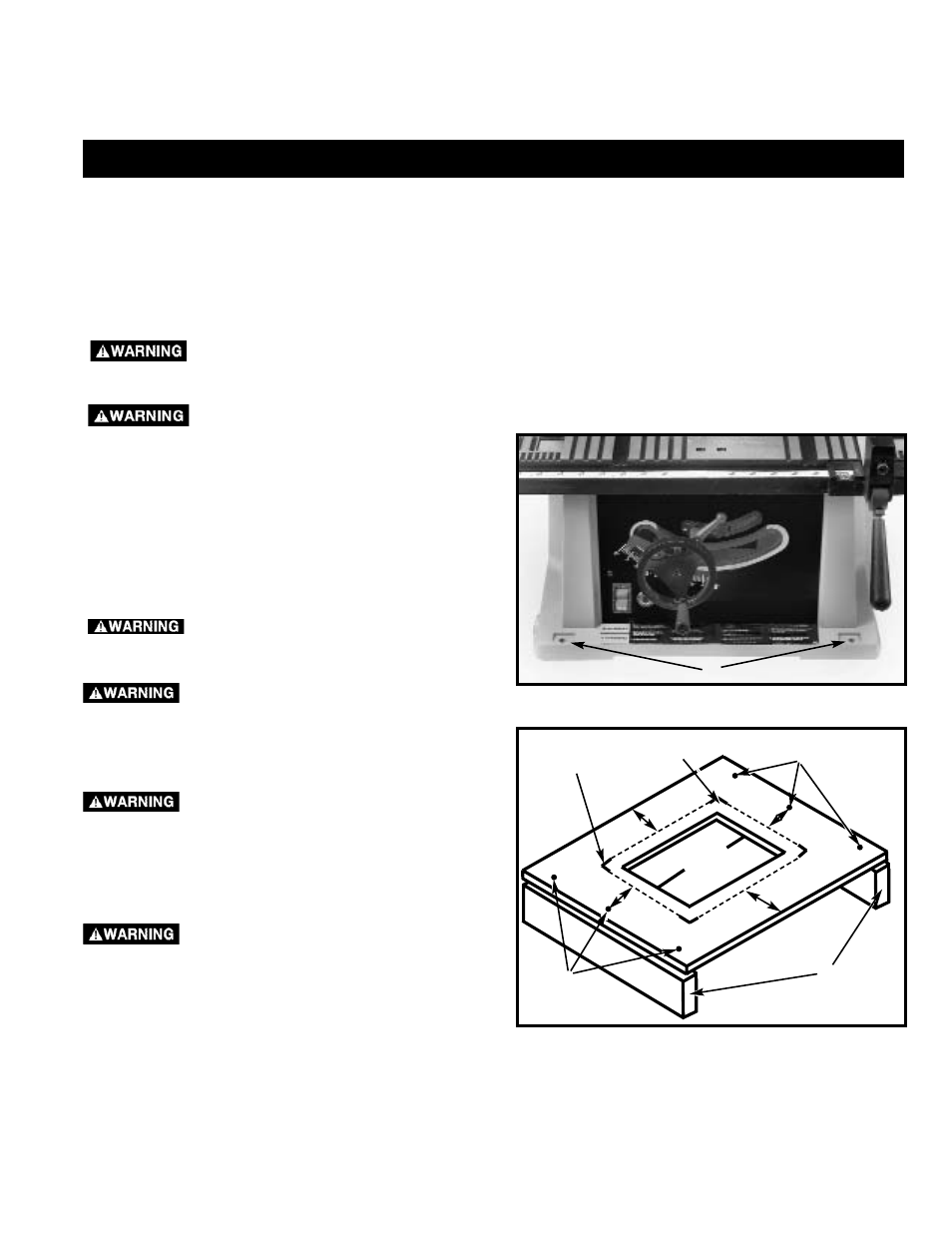

Fig. 4A

ELEVATING AND SUPPORTING SURFACES FOR A SAW WITH NO STAND

A

The saw must be elevated enough for sawdust to fall

through the bottom of the saw and not build up around

the motor.

Position the four mounting holes located on the base of

the saw cabinet (two of which are shown at (A) Fig. 4A)

over whatever proper support you are using. Then

securely fasten the saw to the supports. The saw can be

secured by fastening the stand through the mounting

holes with suitable hardware (not supplied).

THE SAW SUPPORT MUST BE STABLE AND ABLE TO

SUPPORT 300 POUNDS.

You can also construct a simple elevated support, as

shown in Fig. 4B.

USE A GOOD GRADE OF PLYWOOD

WITH A MINIMUM 3/4" THICKNESS.

DO NOT MAKE THE MOUNTING BOARD FROM

PARTICLE BOARD SINCE PARTICLE BOARD

BREAKS EASILY.

A HOLE MUST BE PROVIDED IN THIS

SUPPORT TO ALLOW SAWDUST TO

FALL THROUGH.

Square the saw on the supporting surface and mark the

location for four 5/16 inch holes to be drilled (Fig. 4B).

MAKE SURE THERE IS AT LEAST 3"

ON ALL FOUR SIDES OF THE BASE.

Set the saw aside and then drill holes in these marks.

Locate and mark an 11" or 12" square centered between

the four mounting holes. Cut out and remove the square

(Fig. 4B). To elevate the supporting surface, measure

two 2x4s (A) Fig. 4B to the width of two opposite sides of

the supporting surface. Attach the supporting surface to

the narrow edges of the 2X4s (as shown in Fig. 4B) using

wood screws (not provided) in at least three spots (B)

Fig. 4B on each side.

5/16" PILOT

HOLES

11" OR 12"

SQUARE

CUTOUT

SAW PLACEMENT

MARKS

3" MINIMUM

3" MINIMUM

B

B

A

3" MINIMUM

3" MINIMUM

Fig. 4B

Fasten the saw to the surface by inserting suitable

hardware (not supplied) through the mounting holes on

the saw and into the previously drilled holes. While

using the saw, periodically remove the sawdust buildup

from below the saw.

DISCONNECT MACHINE FROM POWER SOURCE.

9