Product owners manual subwoofer, Hp122 technical data, Hp122 enclosures – Diamond HP15 User Manual

Page 6: Hp152 technical data, Hp152 enclosures, Hp102 technical data, Hp102 enclosures, Features hex™ pro bass driver assembly, A foreword about hex pro subwoofers, Technology

6

©2008 Diamond Audio Technologies. All rights reserved.

HP122 TECHNICAL DATA

HP122

82.4

4

3.98

5.532

0.495

0.454

24.964

36.178

49.0

21.984

19

800/1600

Parameter (unit)

SPL (dB)

Z ( ) {series}

Re ( ) {series}

Qms

Qes

Qts

Fs (Hz)

Vas (L)

Sd (mm

2

)

BL (T*M)

Xmax (mm)

Pwr (W)

NOM/MAX

HP122 ENCLOSURES

The enclosures specified below are offered as suggestions only. Assistance from an authorized

Diamond Audio retailer is recommended for designing the correct system for your vehicle. All

volumes below are shown as gross internal volumes, driver and vent displacement has been

accounted for. The use of a 30 Hz. sub-sonic filter is recommended on most vented enclosures.

Sealed

Vb (ft

3

)

F3 (Hz)

Qtc

Pe (W)

Optimum

1.0

47

0.689

1200

Vented

Vb (ft

3

)

Fb / F3 (Hz)

Port/s (in.)

{dia. x length}

Pe (W)

All Around

1.75

35 / 29

4 x 16

1000

Large

2.0

48

0.59

800

T/S PARAMETERS

HP152 TECHNICAL DATA

HP152

84.495

6.403

3.94

9.418

0.517

0.49

22.239

86.040

81.90

24.564

20.5

1000/2000

Parameter (unit)

SPL (dB)

Z ( ) {series}

Re ( ) {series}

Qms

Qes

Qts

Fs (Hz)

Vas (L)

Sd (mm

2

)

BL (T*M)

Xmax (mm)

Pwr (W)

NOM/MAX

HP152 ENCLOSURES

The enclosures specified below are offered as suggestions only. Assistance from an authorized

Diamond Audio retailer is recommended for designing the correct system for your vehicle. All

volumes below are shown as gross internal volumes, driver and vent displacement has been

accounted for. The use of a 30 Hz. sub-sonic filter is recommended on most vented enclosures.

Sealed

Vb (ft

3

)

F3 (Hz)

Qtc

Pe (W)

High Output

1.65

44

0.747

1500

Vented

Vb (ft

3

)

Fb / F3 (Hz)

Port/s (in.)

{dia. x length}

Pe (W)

All Around

2.5

36 / 32

(2) 4 x 25

1500

High Fidelity

2.0

44

0.703

1500

T/S PARAMETERS

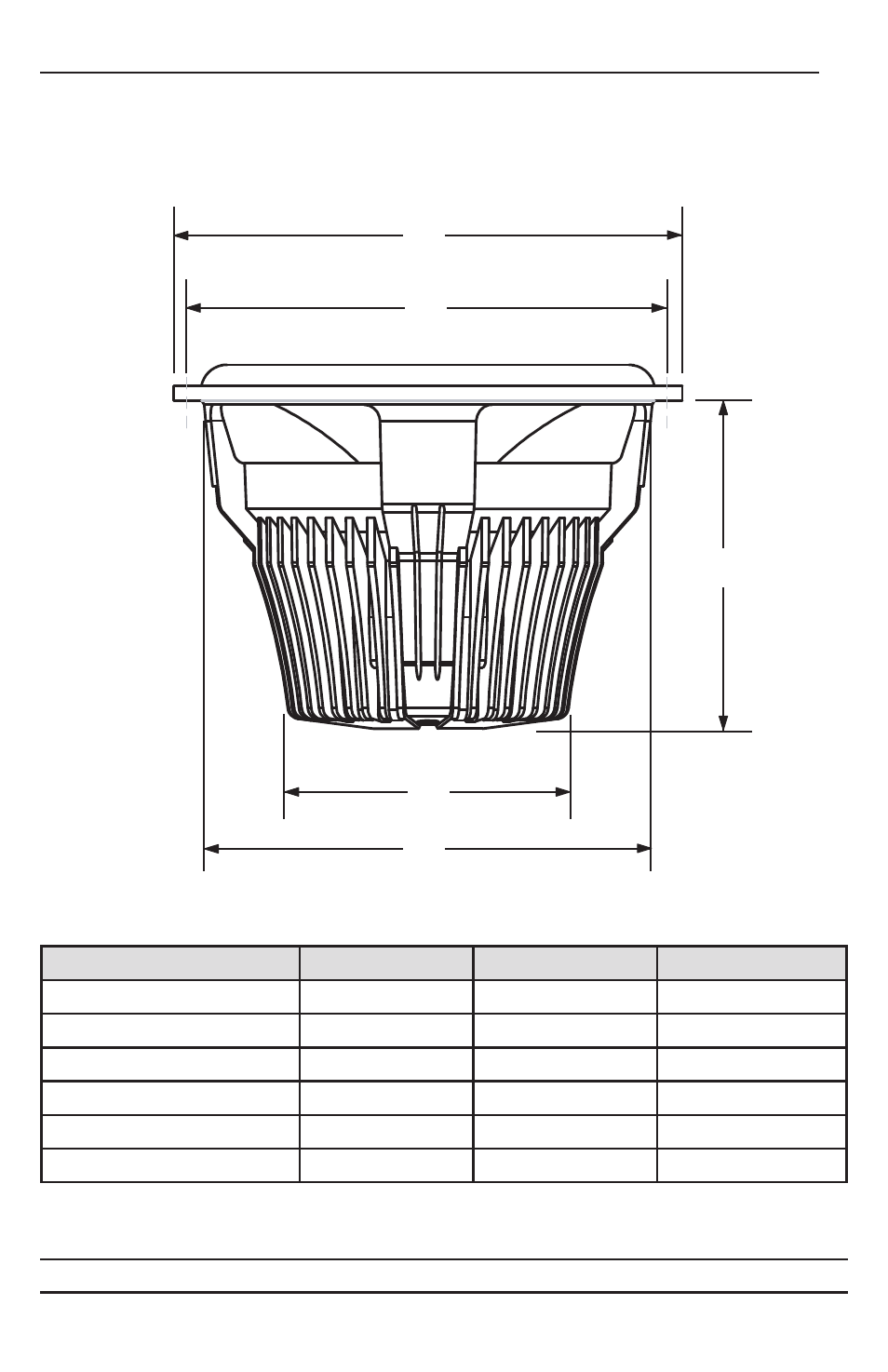

Dimension (inches)

Total Diameter (A)

Mounting Diameter (B)

Screw Hole Diameter (C)

Mounting Depth (D)

Magnet Diameter (E)

Displacement (ft

3

)

HP122

12.4

11.1

11.7

8

6.5

0.15

DIMENSIONS

Dimension (inches)

Total Diameter (A)

Mounting Diameter (B)

Screw Hole Diameter (C)

Mounting Depth (D)

Magnet Diameter (E)

Displacement (ft

3

)

HP152

15.6

14.2

14.8

9.5

7.2

0.22

DIMENSIONS

HP102 TECHNICAL DATA

HP102

79.71

4

3.96

5.822

0.585

0.532

26.109

19.988

33.2

17.971

17

600/1200

Parameter (unit)

SPL (dB)

Z ( ) {series}

Re ( ) {series}

Qms

Qes

Qts

Fs (Hz)

Vas (L)

Sd (mm

2

)

BL (T*M)

Xmax (mm)

Pwr (W)

NOM/MAX

Dimension (inches)

Total Diameter (A)

Mounting Diameter (B)

Screw Hole Diameter (C)

Mounting Depth (D)

Magnet Diameter (E)

Displacement (ft

3

)

HP102

10.7

9.4

9.98

7.5

5.8

0.11

HP102 ENCLOSURES

The enclosures specified below are offered as suggestions only. Assistance from an authorized

Diamond Audio retailer is recommended for designing the correct system for your vehicle. All

volumes below are shown as gross internal volumes, driver and vent displacement has been

accounted for. The use of a 30 Hz. sub-sonic filter is recommended on most vented enclosures.

Sealed

Vb (ft

3

)

F3 (Hz)

Qtc

Pe (W)

Optimum

0.6

51

0.705

1000

Vented

Vb (ft

3

)

Fb / F3 (Hz)

Port/s (in.)

{dia. x length}

Pe (W)

All Around

1.25

42 / 33

4 x 16.25

800

Large

1.25

52

0.592

600

T/S PARAMETERS

DIMENSIONS

(A)

(B)

(C)

(D)

(E)

(A)

(B)

(C)

(D)

(E)

FEATURES

HEX™ PRO BASS DRIVER ASSEMBLY

TDX Technology™ (Thermal Dyne eXtreme)™

Proprietary Composite Hex Cone Technology

Nitrile Butadine Rubber (NBR) Surrounds

Die-cast Aluminum Frames

Dual Progressive Poly-Aramid Composite Fiber Spiders

Integrated Radial Venting

Aluminum Dust Cap

Ultra-high Energy Neodymium Magnet Structure

Vented Pole Piece

Huge 3" (HP10), 3 ½" (HP12), and 4" (HP15) Voice Coils

Dual 2 ohm Voice Coils

A FOREWORD ABOUT HEX PRO SUBWOOFERS

(A)

(C)

(E)

(B)

(B)

Thermal-Dyne eXtreme

™

, a fundamentally different solution. The design concept of TDX

™

subwoofer technology was to start with a fresh sheet of paper and build a new product that

addressed all of the problems and shortcomings of conventional subwoofer designs while

significantly raising the existing level of performance. In today's market, a subwoofer should be

optimized for use in a relatively compact enclosure, should handle extreme levels of power, and

displace (or move) a large volume of air without any audible distortion. Conventional subwoofers,

with their dated materials and motor structures compromise several of these requirements.

The "fundamentally different" TDX

™

subwoofer technology meets all these requirements in

unequaled, elegant fashion. We say fundamentally different because the heart, the motor

structure, of this incredible device is unlike any existing motor today. Because of its superior

design, many of the problems that plague existing conventional subwoofers are eliminated.

To understand TDX

™

speaker technology, it must first be compared to that of a conventional

speaker design. At the heart of every speaker is a permanent magnet motor structure that

provides the magnetic energy, or force to move the voice coil back and forth within the magnetic

air gap. Conventional speakers use a large ceramic magnet surrounding the voice coil that

actually retains heat rather than dissipating it. TDX

™

motors use a small but very efficient high

temperature Neodymium magnet mounted inside the voice coil. The geometry, venting and

material selection for the motors have all been optimized for ideal thermal dissipation. The TDX

™

thermal efficiency is nearly (5) times greater than conventional designs. In conjunction with the

motor design, TDX

™

Technology utilizes die-cast aluminum frame structures to act as a heat sink

for the encapsulated motor structure. To insure maximum heat transfer from the encapsulated

motor case to the aluminum frame, a special thermal paste fills any surface voids that may

present in this mating surface.

In addition to this superior motor structure, the HEX

™

PRO subwoofer incorporates a dual

mirrored spider and NBR surround suspension system, and our patented HEX

™

cone technology.

The result is the most dynamic performing sub woofer in mobile electronics reaching the design

goal of audiophile sound quality performance, SPL capabilities, and continuing the Diamond Audio

tradition of providing the finest products available.

TDX

™

TECHNOLOGY

Product Owners Manual

SUBWOOFER

Dear Valued Customer,

All of us at Diamond Audio would like to thank you for your purchase of a HEX Pro speaker system. HEX

Pro component systems and subwoofers are the very best speakers available for use in the automobile

environment. By choosing thses products you recognize the value in using only the best. With our

proprietary HEX

™

cones and neo motors that utilize our patented TDX

™

technology, we know you will be

satisfied with these systems for years to come.

Please keep in mind that prolonged exposure to sound pressure levels in excess of 100 dB can cause

permanent hearing loss. This high performance speaker system can exceed that level, so please

exercise restraint in its operation in order to preserve your ability to enjoy its fidelity in the future.

Because of their flexible installation possibilities, please consider having your new speakers

professionally installed by an authorized Diamond Audio dealer. This will assure a clean and efficient

installation, and extend your one year warranty to three years.

At Diamond Audio Technologies, we strive to bring honest value and excellent quality to all of the

products we build. By your purchase of this product, you have joined the growing family of discerning

listeners who demand only the best. Welcome!

The Diamond Audio Team

WARRANTY

Diamond Audio Technologies

6915 W. Frye Road

Chandler, Arizona 85226 USA

PHONE:

(480) 820-2075

FAX:

(480) 813-6210

SERVICE/TECH SUPPORT:

480-820-2075

TECH SUPPORT EMAIL:

WEB:

www.diamondaudio.com

Diamond Audio warrants this product to be free from defects in material and workmanship under normal use

for a period of one (1) year from date of original purchase. Should service be necessary under this warranty

for any reason due to manufacturing defect or malfunction during the warranty period, Diamond Audio will

replace or repair (at our discretion) the defective merchandise at no charge.

This warranty is valid only to the original purchaser and is not extended to owners of the product subsequent

to the original purchaser. Any applicable implied warranties are limited in duration to a period of the express

warranty as provided herein beginning with the date of the original purchase at retail, and no warranties,

whether expressed or implied, shall apply to this product there after. Some states do not allow limitations on

implied warranties; therefore these exclusions may not apply to you.

This warranty gives you specific legal rights; however you may have other rights that vary from state to state.

If your Diamond Audio speakers need service, defective merchandise must be returned to your local

Authorized Diamond Audio dealer for warranty. Return only the defective component. Non-defective items

received will be returned freight collect. Freight damage and return shipping is not covered under warranty.

Include proof-of-purchase with the returned items. Warranty expiration on items returned without

proof-of-purchase will be determined from the manufacturing date code. You can confirm that a dealer is

authorized for service by the display of a current authorized dealer window decal. Any questions can be

directed to the Warranty Department at (480) 820-2075. This warranty is valid only if the product is used for

the purpose for which it was designed. It does not cover:

s

PHYSICAL DIMENSIONS

Dimension (Inches)

HP10

HP12

HP15

Total Diameter (A)

10.7” (272mm)

12.4” (315mm)

15.6” (396mm)

Mounting Diameter (B)

9.4” (239mm)

11.1” (282mm)

14.2” (360mm)

Screw Hole Diameter (C)

9.98” (254mm)

11.7” (297mm)

14.8” (376mm)

Mounting Depth (D)

7.5” (191mm)

8” (203mm)

9.5” (241mm)

Magnet Diameter (E)

5.8” (147mm)

6.5” (165mm)

7.2” (183mm)

Displacement

0.11 ft

3

(3.11 liter)

0.15 ft

3

(4.24 liter)

0.22 ft

3

(6.23 liter)