Maintenance – Delta 66-202-1 User Manual

Page 13

13- ENG

D27456

MAINTENANCE

Customer Responsibilities

Daily or after

each use

Before each use

Check Safety Valve

●

Drain Tank

●

To Check Safety Valve

If the safety valve does not work properly, over-

pressurization may occur, causing air tank rupture

or an explosion. Before starting compressor, pull the ring on the safety

valve to make sure that the safety valve operates freely. If the valve is

stuck or does not operate smoothly, it must be replaced with the

same type of valve.

To Drain Tank

1.

Set the On/Auto/Off lever to "OFF".

2.

Pull the regulator knob out and turn clockwise to set the outlet pressure to

zero.

3.

Remove the air tool or accessory.

4.

Pull ring on safety valve allowing air to bleed from the tank until tank

pressure is approximately 20 psi. Release safety valve ring.

5.

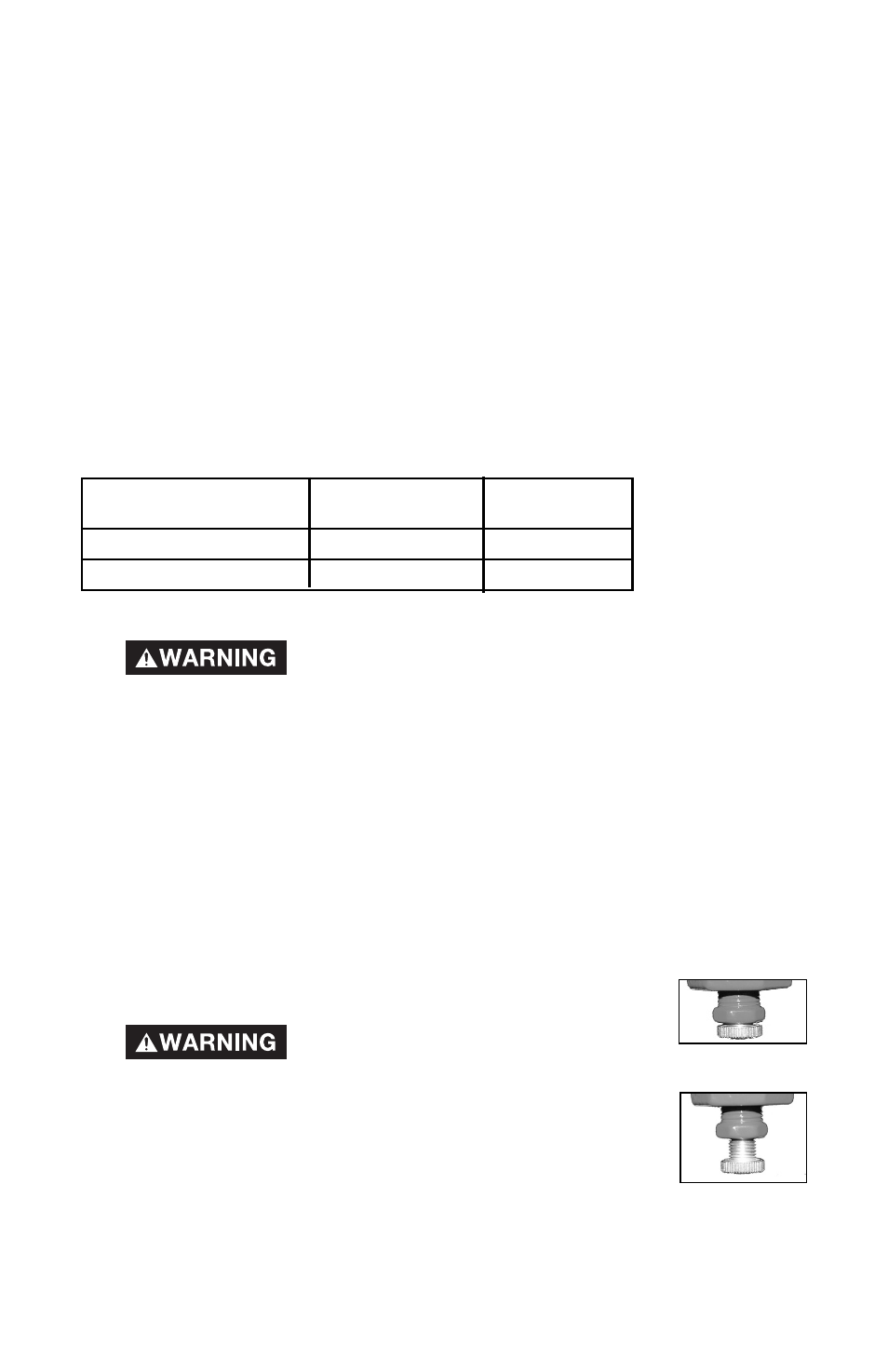

Drain water from air tank by opening drain valve on bottom

of tank.

Water will condense in the air tank. If not

drained, water will corrode and weaken

the air tank causing a risk of air tank rupture.

6.

After the water has been drained, close the drain valve. The

air compressor can now be stored.

NOTE: If drain valve is plugged, release all air pressure. The

valve can then be removed, cleaned, then reinstalled.

How to Start:

1.

Turn the On/Auto/Off lever to "AUTO" and allow tank pressure to build.

Motor will stop when tank pressure reaches "cut-out" pressure.

2.

Turn regulator knob clockwise to increase pressure and stop when desired

pressure is reached. The compressor is ready for use.

NOTE: Always operate the air compressor in well-ventilated areas free of

gasoline or other combustible vapors. If the compressor is being used to

operate a sprayer DO NOT place near the spray area.

Open Drain

Valve

Closed Drain

Valve