Maintenance troubleshooting – Delta 31-260X User Manual

Page 18

18

1. Tighten the four table mounting bolts, nuts, and the

four bolts that attach the elevating bolts to the support

plate.

2. Loosen the timing belt tension (see STEP 1).

3. With a 7/16" open-end wrench, loosen, but do not

remove, the four nuts (N) Fig. 43 that secure the right

side elevating bolts.

4. Lift the right end of the table to see if the sheet metal

flanges are free. Lower the table and, to position it,

shake it slightly.

5. Retighten the four hex nuts. Tension the belt (See

STEP 1).

6. If the table movement is still tight, loosen the belt tension. Use a 1/2" open-end wrench to loosen the two nuts on the

front left elevating bolt.

7. Again, lift the left side of the table to see if the flanges are free.

8. Tighten the two hex nuts. Tension the belt.

9. Adjust

the

table.

NOTE: The torque required to move the table assembly should be 30 inch/lbs. If this is not the case, repeat the entire proce-

dure again.

Make certain the machine is disconnected from the power source before performing maintenance

procedures.

1. Periodically clean or vacuum the feed belt.

2. Periodically clean the sawdust from sanding cylinder cavities.

3. Oil all bushings on the feed table rollers and front and rear pressure rollers.

4. Oil thrust bearings on feed table bolts [See (T) Fig. 41].

MAINTENANCE

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltaportercable.com for a list of service centers or call the

DELTA MACHINERY HELP LINE at 1-800-223-7278 (In Canada call 1-800-463-3582).

STEP 4 - ALIGNING ELEVATING BOLT BUSHINGS

Fig. 42

N

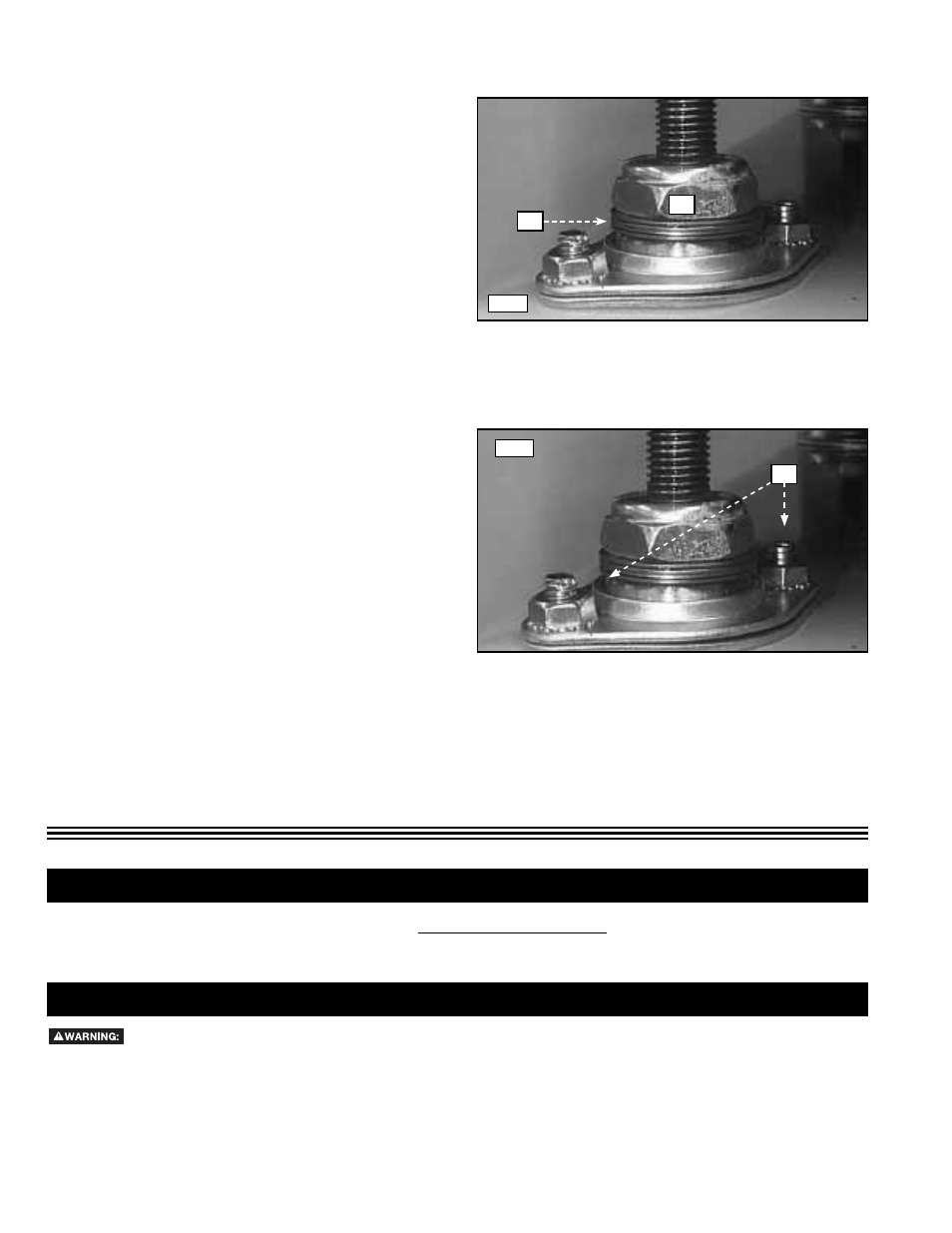

1. A 3/4" locknut is on the base of three of the elevating

bolts (B) Fig. 42. Under this nut is a thrust washer,

thrust bearing, and another thrust washer (T) Fig. 42.

Note: The front left elevating bolt uses a jam nut that

should remain tight.

2. Tighten the lock nut so that you can slide the thrust

washers from side to side, but not up and down.

3. If the locknut is too tight, the table will be hard to

move. If the lock nut is too loose, sanding will not be

accurate.

4. To adjust, locate the 2" hex nut on the under side of

the unit, under the elevating bolt. Hold this with a 2"

open wrench or a pair of pliers. Use a 1-1/16" wrench

to loosen or tighten the locknut on the topside.

STEP 3 - CHECKING THE LOCK NUT ADJUSTMENT

Fig. 41

Note: Make small adjustments (1/16 turn at a time or less) to prevent damage.

B

T