Assembly, Warning, Caution – Dremel 400 SERIES DIGITAL 398-49 User Manual

Page 6

Page 6

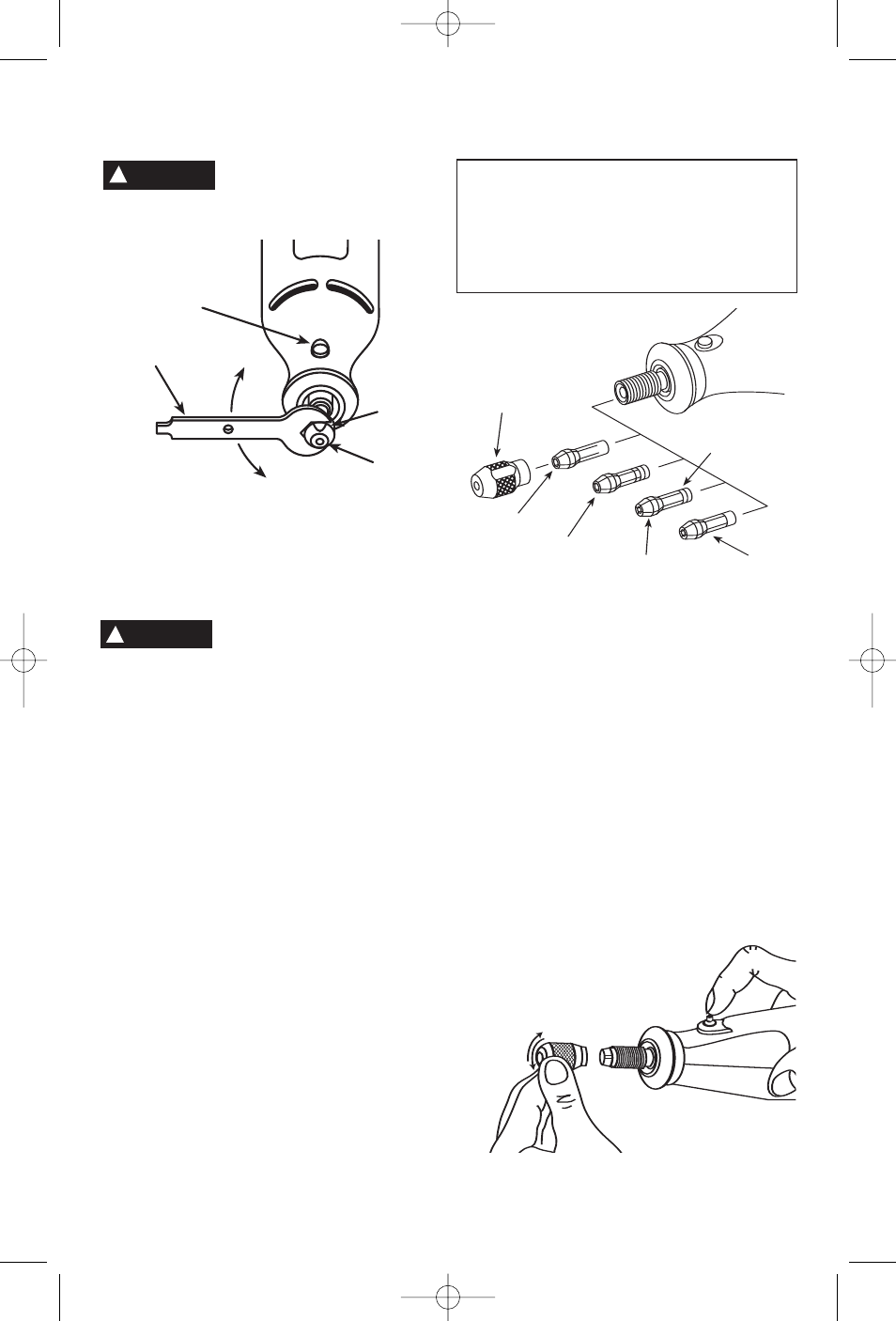

COLLET

To loosen, first press shaft lock button and rotate the

shaft by hand until the lock engages the shaft

preventing further rotation.

Do not engage lock while the

Rotary Tool is running.

With the shaft lock engaged use the collet wrench to

loosen the collet nut if necessary. Change accessories

by inserting the new one into the collet as far as

possible to minimize runout and unbalance. With the

shaft lock engaged, finger tighten the collet nut until the

accessory shank is gripped by the collet. Avoid

excessive tightening of the collet nut.

COLLETS

Four different size collets (see illustration), to

accommodate different shank sizes, are available for

your Rotary Tool. To install a different collet, remove the

collet nut and remove the old collet. Insert the unslotted

end of the collet in the hole in the end of the tool shaft.

Replace collet nut on the shaft. Always use the collet

which matches the shank size of the accessory you

plan to use. Never force a larger diameter shank into a

collet.

BALANCING ACCESSORIES

For precision work, it is important that all accessories

be in good balance (much the same as the tires on your

automobile). To true up or balance an accessory, slightly

loosen collet nut and give the accessory or collet a 1/4

turn. Retighten collet nut and run the Rotary Tool. You

should be able to tell by the sound and feel if your

accessory is running in balance. Continue adjusting in

this fashion until best balance is achieved. To maintain

balance on abrasive wheel points, before each use, with

the wheel point secured in the collet, turn on the Rotary

Tool and run the 415 Dressing Stone lightly against the

revolving wheel point. This removes high spots and

trues up the wheel point for good balance.

The hanger is provided for the use of hanging your

tool while using the flex-shaft or for storage. If you do

not use the hanger, remove it from the tool and snap

it back into place underneath the cord so it will be out

of the way while the tool is in use.

FLEX-SHAFT TO ROTARY TOOL INSTALLATION

To properly attach the flex-shaft to the rotary tool,

THREE items must be removed from the tool: the

housing cap, collet nut and collet.

Step 1. Press the Shaft lock button, unscrew and

remove the collet nut.

Step 2. Unscrew the housing cap from the tool.

COLLET

COLLET

NUT

TO LOOSEN

TO TIGHTEN

COLLET

WRENCH

COLLET IDENTIFICATION CHART — Collet sizes can

be identified by the rings on the back end of collet.

0,8mm Collet has one (1) ring.

1,6mm Collet has two (2) rings.

2,4mm Collet has three (3) rings.

3,2mm Collet has no rings.

Always unplug Rotary Tool before

changing accessories, changing

collets or servicing your Rotary Tool.

SHAFT LOCK

BUTTON

COLLET

NUT

IDENTIFICATION

RINGS

480

3,2mm

COLLET

481

2,4mm

COLLET

482

1,6mm

COLLET

483

0,8mm

COLLET

WARNING

!

Assembly

!

CAUTION

DM 2610934164 05-06 10/6/06 8:41 AM Page 6