Maintenance, Lubrication – Delta DP350 User Manual

Page 15

15

LUBRICATION

DISCONNECT MACHINE FROM POWER

SOURCE.

1.

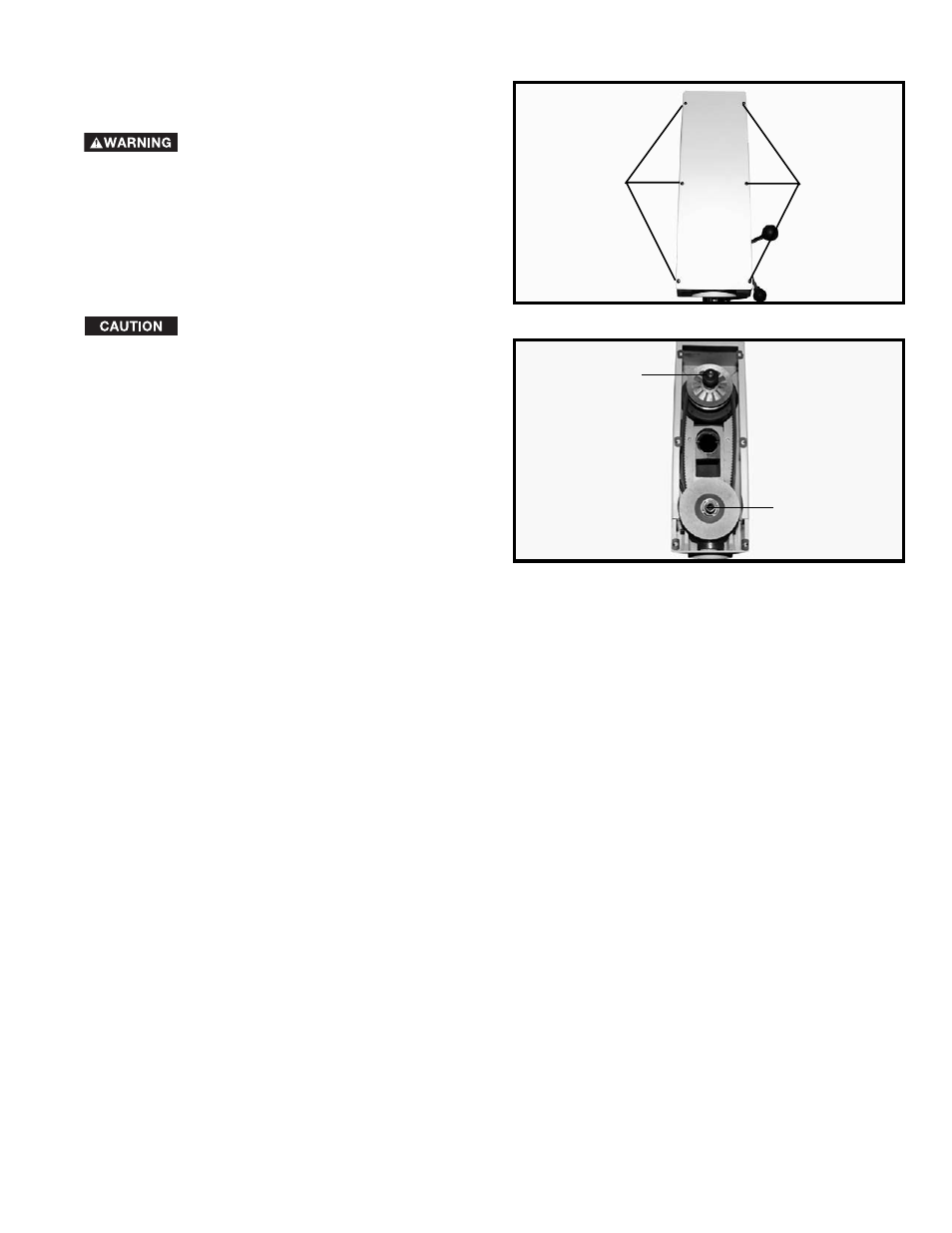

Remove the six screws (A) Fig. 30 that hold the top

cover in place, and remove the top cover.

2.

The variable speed pulleys should be oiled weekly

with a few drops of light machine oil in the two oil holes

(B) Fig. 31, located on top of the variable speed pulleys.

Oil the holes when the drill press is

turned OFF. Then turn the machine ON and run

through the low and high speed ranges a few times.

Fig. 30

Fig. 31

A

A

B

B

MAINTENANCE

See also other documents in the category Delta Tools:

- 340-WE-DST (1 page)

- 3584 Series (8 pages)

- 23-725 (16 pages)

- 520-WF (1 page)

- DC-580 20" PLANER 22-451 (24 pages)

- Victorian 3555-LHP (1 page)

- 2171 (1 page)

- 503-WF (1 page)

- 481 Series (2 pages)

- 1837 (2 pages)

- 46-756 (24 pages)

- 13" PORTABLE PLANER 22-590 (52 pages)

- 2520 Series (8 pages)

- 488 Series (8 pages)

- ShopMaster SM300 (51 pages)

- 187 Series (1 page)

- 174 Series (8 pages)

- 100-WF-10 (1 page)

- 2302-LHP (1 page)

- HDS 3000 (1 page)

- TP305 (49 pages)

- 4551 (1 page)

- 502 Series (8 pages)

- 402-WF (1 page)

- 1324 (2 pages)

- 340-WF (1 page)

- 70-200 (17 pages)

- 46-462 (8 pages)

- 117-DST (12 pages)

- 1343-NPS (2 pages)

- 15915 Series (6 pages)

- 50102 Series (4 pages)

- DNS100 (15 pages)

- 403-WF (1 page)

- 11-985 (16 pages)

- 144915 (1 page)

- 2530-LHP (1 page)

- Victorian 2755 Series (5 pages)

- 2785 Series (2 pages)

- 187-WF (1 page)

- 15910 (6 pages)

- 3544-WFMPU (1 page)

- 2400LF (1 page)

- 16968-DST Series (40 pages)