Making the cut, crown molding, Bevel and miter angles for crown molding cuts, Using a custom angle – Starrett CP505E-12 Electronic Protractor User Manual

Page 2: How to determine the crown molding spring angle

978-249-3551

starrett.com

specifications subject to change.

1M/Q

Form 970

01/12

2

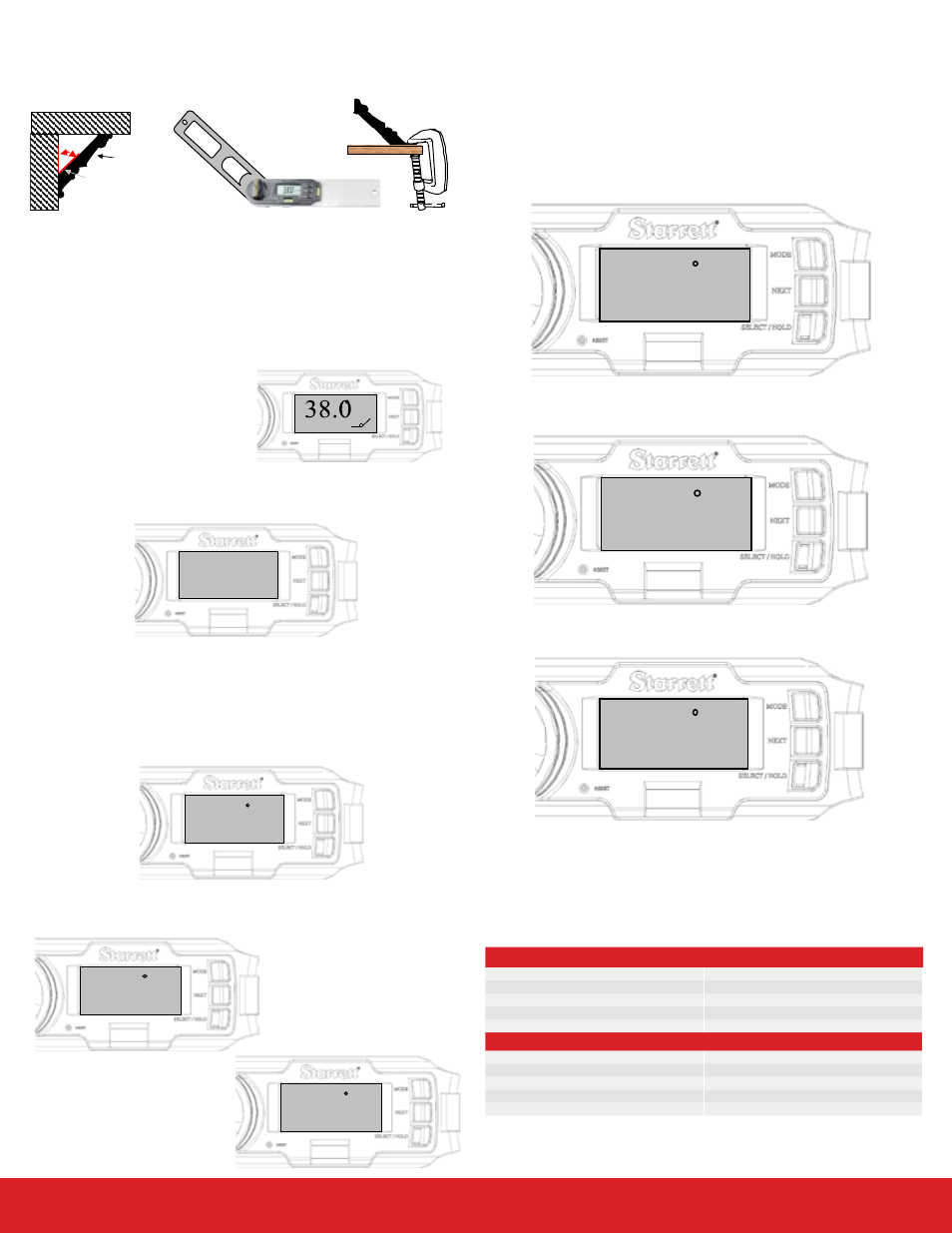

inside Corner

Left Piece

right Piece

Work Piece Location: Left to Blade

Work Piece Location: Left of Blade

Miter Swing: Right

Miter Swing: Left

Bevel Swing: Left

Bevel Swing: Left

Molding Edge Against Fence: Top

Molding Edge Against Fence: Bottom

outside Corner

Left Piece

right Piece

Work Piece Location: Right of Blade

Work Piece Location: Right of Blade

Miter Swing: Left

Miter Swing: Right

Bevel Swing: Right

Bevel Swing: Right

Molding Edge Against Fence: Bottom

Molding Edge Against Fence: Top

Use the chart below for settings and layout for crown molding cuts with a

compound miter saw.

Making the Cut, Crown Molding

ADJUST SAW FOR BEVEL

SPRING

CROWN

34.2

ADJUST SAW FOR MITER

SPRING

38

CROWN

32.1

Bevel and Miter angles for Crown Molding Cuts

Press the

Mode button until CroWn is displayed. Press the neXt button to

select the spring angle that coincides with your molding. Choices are 38°,

45°, 52°, or Custom.

Use the

seLeCt/HoLd button to lock in this value. Open the tool and place it

in the corner to be measured. Note the value in degrees (Fig. 18).

Press the

neXt

button to display the miter saw blade setting (Fig. 19).

MEASURE

CORNER

SPRING

38

CROWN

89.0

Fig. 18

Fig. 19

Fig. 20

Press NEXT

again to display the bevel angle setting (Fig. 20).

ADJUST SAW FOR MITER

SPRING

CUST

CROWN

39.4

ADJUST SAW FOR BEVEL

SPRING

CUST

CROWN

23.9

MEASURE

CORNER

SPRING

CUST

CROWN

55.0

To determine the miter angles using a custom spring angle, sequence

through

Mode

to get to CroWn, then push the neXt button until CUS is

displayed (Fig. 14).

Press the

seLeCt/HoLd button to set the spring angle. Move the arm of the

protractor until the display shows the value of your custom angle (Fig. 15).

Then Press the

neXt

button and measure the corner angle.

If you find that your molding is not one of the standard spring angles using

the steps above, use the custom option to determine the angles for your cut.

First, write down your custom angle (Fig. 15).

Press

neXt to attain the miter angle (Fig. 16). Then press neXt and set your

blade to the bevel angle displayed (Fig. 17).

SET SPRING

CUST

CROWN

CUS

Fig. 14

Fig. 15

Fig. 17

using a Custom angle

Fig. 16

Measure

PROTRACTOR

38.0

Wall

Spring Angle

Crown Molding

Ceiling

How to determine the Crown Molding spring angle

The spring angle of crown molding stock is the angle from the back of the

molding to the wall. While the spring angle is stamped on some stock, it is

preferable to verify the measurement.

To make this measurement, place the molding on the edge of a work bench

and set the material so the edge that will come into contact with the wall is

facing down on to the surface of the bench.

The molding will be on an angle. Lightly clamp the molding to hold in place

(Fig. 11). Place the 505E under the bench top and open the arm so it mimics

the angle of the molding. Place the 505E as shown in Fig. 12, then press

neXt

and cycle through to the obtuse setting as shown in Fig. 13. This will be

your spring angle. Common angles are 38°, 45°, or 52°.

Fig. 10

Fig. 12

Fig. 13

Fig. 11