Basic elements of an engine – DeVillbiss Air Power Company DVH2600 User Manual

Page 10

10- ENG

A16064

BASIC ELEMENTS OF AN

ENGINE

Refer to the engine manual for location

and operation of engine controls.

Choke Control: Opens and closes

carburetor choke valve.

Starter Grip: Pulling starter grip

operates recoil starter to crank engine.

Engine Switch: Enables and disables

ignition system.

PRESSURE WASHER

TERMINOLOGY

PSI: Pounds per Square Inch. The

unit of measure for water pressure.

Also used for air pressure, hydraulic

pressure, etc.

GPM: Gallons Per Minute. The unit of

measure for the fl ow rate of water.

CU: Cleaning Units. GPM multiplied

by PSI. GPM x PSI = CU

Bypass Mode: Allows water to

re-circulate within pump when the gun

trigger is not pulled.

Allowing the unit to

run for more than

two minutes without the gun trigger

pulled could cause overheating and

damage to the pump.

Chemical Injection System: Mixes

cleaners or cleaning solvents with

the water to improve cleaning

effectiveness.

Water Supply: All pressure washers must

have a source of water. The minimum

requirements for a water supply are 20

PSI and 5 gallons per minute.

PRESSURE WASHER

OPERATING FEATURES

PRESSURE ADJUSTMENTS

The pressure setting is preset at the

factory to achieve op ti mum pres sure

and cleaning. If you need to lower the

pres sure, it can be accomplished by

these meth ods.

1. Back away from the sur face to

be cleaned. The further away you

are, the less the pressure will be

on the surface to be cleaned.

2. Change to the 40º nozzle -

(white) this nozzle delivers a less

powerful stream of water and a

wider spray pattern.

DO NOT attempt

to increase pump

pressure. A higher pressure setting

than the factory set pressure may

damage pump.

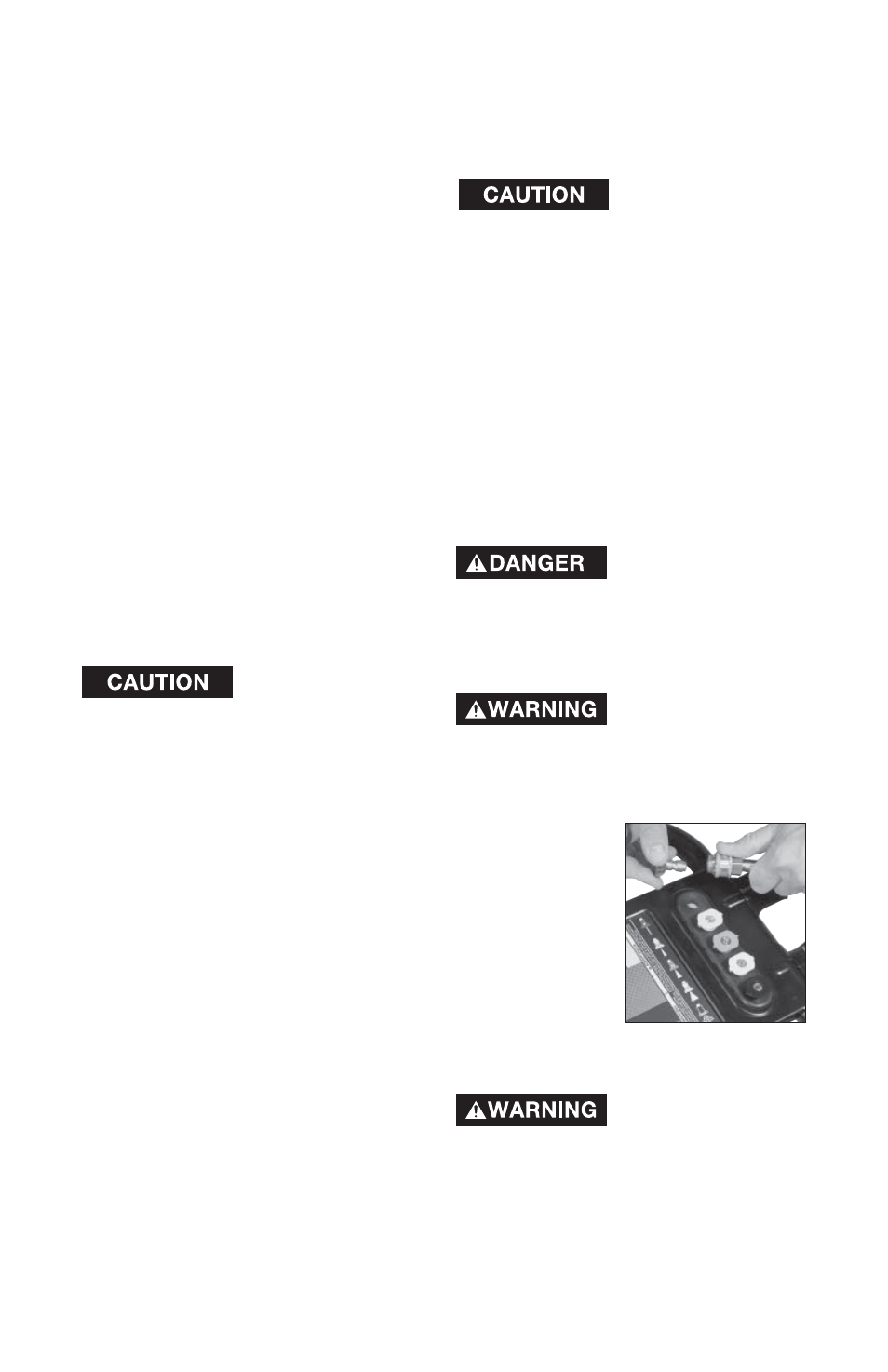

SPRAY WAND NOZZLES

The nozzles for the spray wand are

stored in the nozzle holder on the panel

assembly. Colors on the panel identify

nozzle location and spray pattern.

Refer to the following chart to choose

the correct nozzle for the job to be

performed.

CHANGING NOZZLES ON

SPRAY WAND

Risk of fluid

injection. Do not

direct discharge stream toward

persons, unprotected skin, eyes or

any pets or animals. Serious injury will

occur.

Flying objects

could cause risk

of serious injury. Do not attempt

to change nozzles while pressure

washer is running. Turn engine off

before changing nozzles.

1. Pull

quick-

connect

coupler back

and insert

nozzle.

2. Release

quick-

connect

coupler

and twist nozzle to make sure it is

secure in coupler.

Flying object could

cause risk of serious

injury. Ensure nozzle is completely

inserted in quick-connect socket

and quick-connect snap ring is fully

engaged (forward) before squeezing

gun trigger.