Semi-micro operations, Alternate parts, Maintenance instructions – Parr Instrument Series 3900 User Manual

Page 11: Fuse ratings, Hydrogenation apparatus

Hydrogenation Apparatus

w w w . p a r r i n s t . c o m

11

Semi-micro Operations

Small samples can be treated in a 3911 Hydrogena-

tor by replacing the standard 500 mL bottle with

a smaller 250 mL bottle (66CA2). This requires a

101CA2 spacer to compensate for the difference in

bottle heights. To install the 250 mL bottle, remove

the stopper and the 61CA4 washer from the gas

inlet tube and slide the 101CA2 spacer onto the tube,

then clamp the bottle and spacer in the holder in

the usual manner. Since small samples may require

only small amounts of hydrogen, it may be advanta-

geous to replace the standard four liter hydrogen

tank with an alternate one liter tank (A16CA2) for

semi-micro operations. The same tank valves are

used on both sizes and are easily transferred to the

small tank.

Augustine (reference 1 on page 15) describes an

interesting holder for handling small samples in a

3911 Hydrogenator which he prepares by sealing a

50 mL or smaller heavy walled fl ask inside a larger

bottle.

Alternate Parts

If bottle pressure measurements are not required,

the gage can be removed from the 3A93CA valve

assembly and replaced with a 94CA plug.

Tefl on tubing can be furnished in place of the stan-

dard 119CA polypropylene tube for use with chemi-

cals which might attack polypropylene. The same

fi ttings are used to attach either Tefl on or polypropyl-

ene tubing to the 3A93CA valve.

Maintenance Instructions

Periodic cleaning may be performed on the exterior

surfaces of the instrument with a lightly dampened

cloth containing mild soap solution. All power

should be disconnected when cleaning the instru-

ment. There are no user serviceable parts inside the

product other than what is specifi cally called out

and discussed in this manual. Advanced trouble-

shooting instructions beyond the scope of this

manual can be obtained by calling Parr Instrument

Company in order to determine which part(s) may

be replaced or serviced.

The connecting rod has oil-impregnated bronze

bearings which do not require heavy lubrication.

Place a drop or two of light oil on each bearing

about once a month. Lubricate the fl ywheel shaft

by placing a few drops of light oil in the oil cup at

regular intervals. A light application of a lithium

grease such as “Lubriplate” on the shaker pivots is

also advisable. The spacing of these pivots should

be adjusted so that the bottle clamp swings freely

without excessive friction.

To inspect and replace the valves, unscrew the 8VB2

packing nut and remove the needle and knob. The

internal parts can then be removed with a small

wire hook. These will come out in the following se-

quence: 6VB packing cover, two 4VB3 packing rings,

21VB lantern ring, and 20VB valve seat. If the plastic

valve seat will not slide out of its socket, use a 1

1/2” wood screw as a removal tool. Replace these

parts in the same order; insert the valve needle and

tighten the 8VB2 packing nut fi rmly with a wrench.

Caution: Always back the valve needle away from its

seat before tightening the packing nut.

It will be necessary to use a new plastic ferrule in

the A102CA connector whenever a new polypropyl-

ene tube is installed. A new A102CA connector is

furnished with each replacement A154CA polypro-

pylene tube so that a complete set of parts will be

available when changing tubes. If the body and cap

nut in the old connection are in good condition they

can be used with the ferrule from the new connec-

tor. But if there is any question about the old parts,

discard them and install a new connector. The steps

required to attach the tube to the connector are as

follows: Be sure that the end of the tube has been

cut squarely; then disassemble the connector and

slide the cap nut and ferrule onto the tube. Insert the

tube into the connector body and tighten the cap

nut fi rmly.

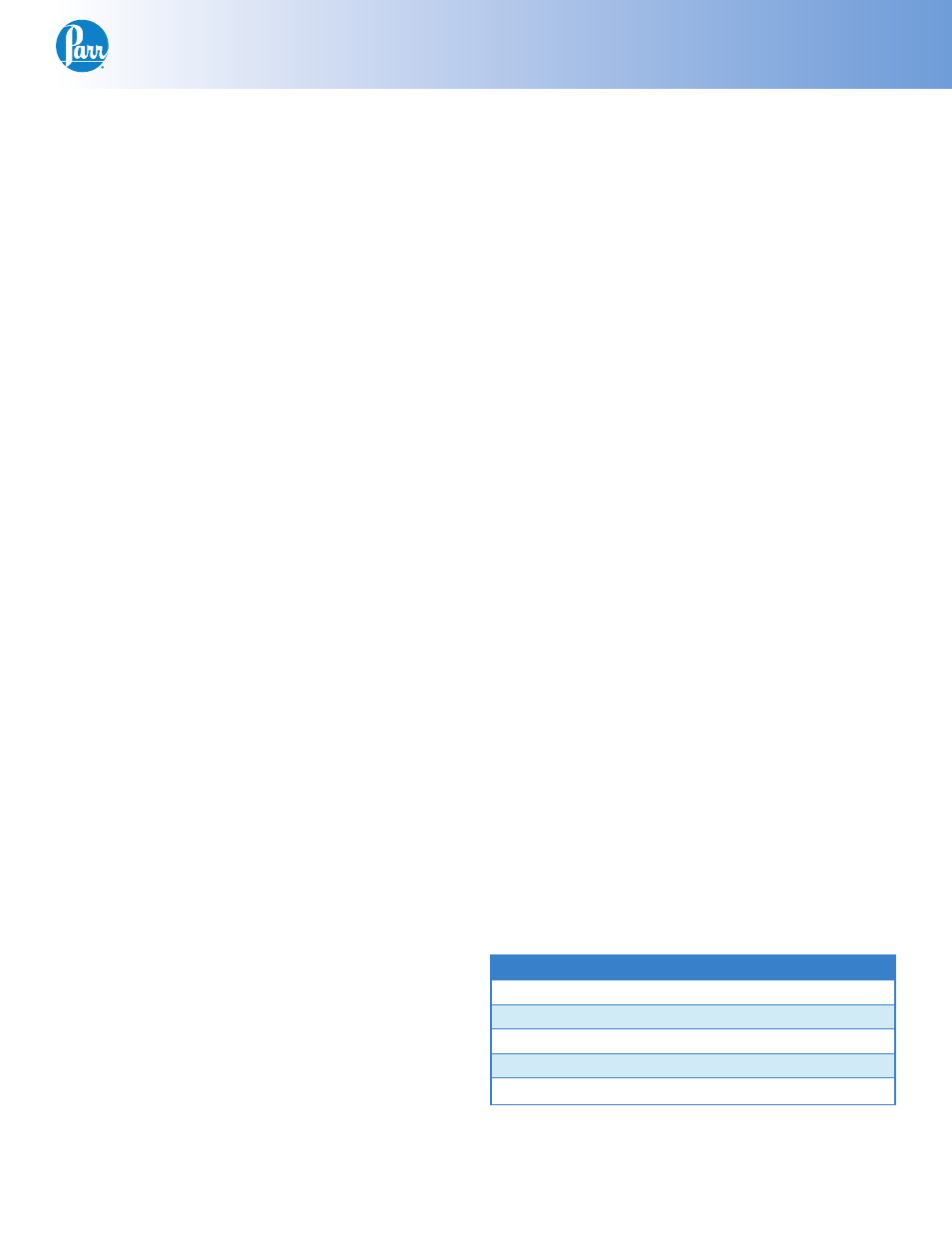

Fuse Ratings

The replacement of protective fuses should be per-

formed by qualifi ed personnel.

Parr No.

Type

Ratings

139E21

Slo-blo

5 Amps, 250 Vac

139E20

Slo-blo

4 Amps, 250 Vac

139E8

Slo-blo

2.5 Amps, 250 Vac

139E25

Slo-blo

10 Amps, 250 Vac

139E26

Slo-blo

6 Amps, 250 Vac

Note:

Check the labels on Switch Box for cor-

rect fuse rating.