NIBCO High-Performance Butterfly Valve User Manual

Page 5

A H E A D O F T H E F L O W

®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

5

®

Revised 8/22/2013

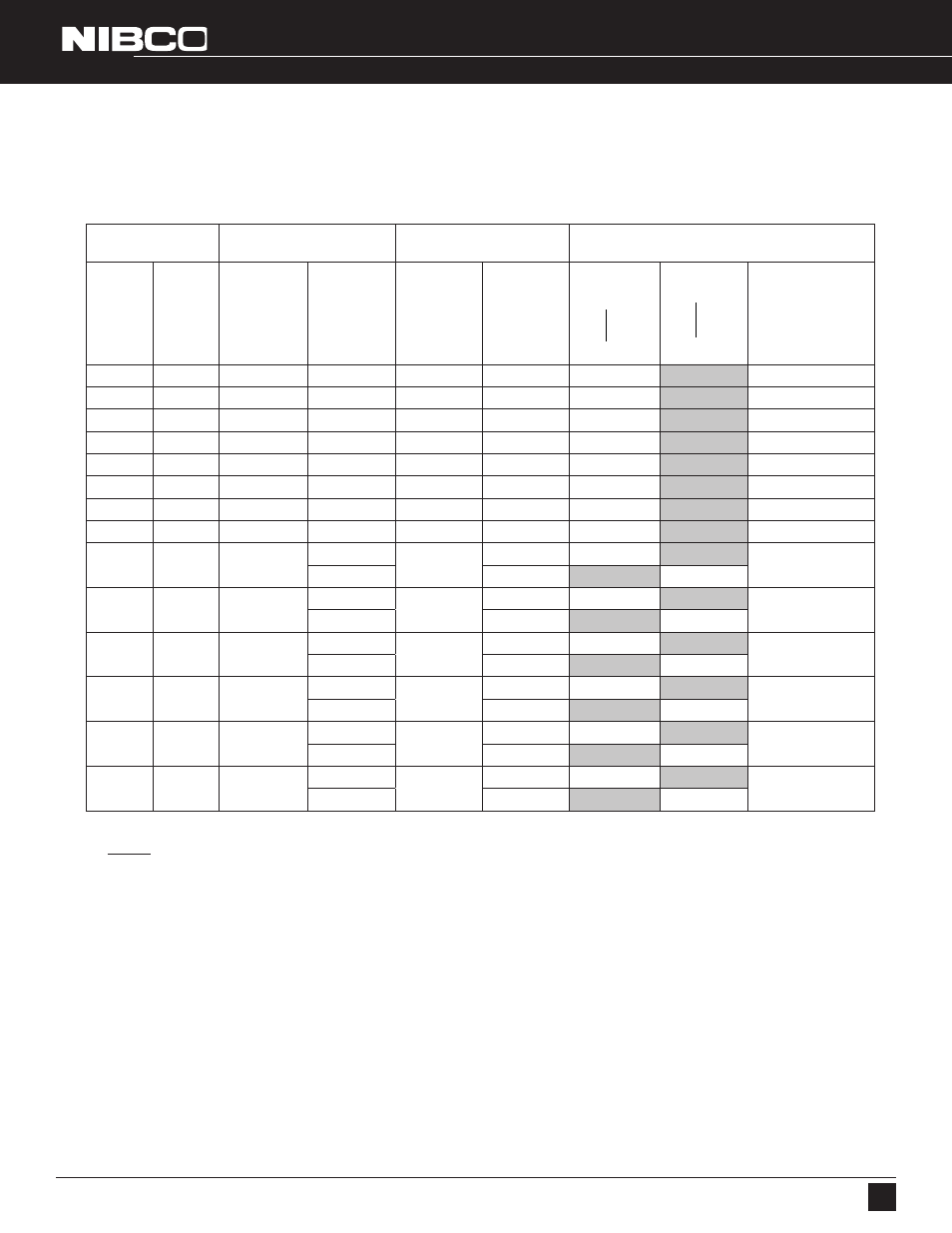

LCS-7822 CLASS 300 HPBFVs

6. Operation:

6.1 The valve can be actuated by a manual lever, a manual gear operator, an electric actuator, or a pneumatic actuator. Turning

the valve (as viewed from top) clockwise closes the valve; counter-clockwise opens the valve.

6.2 Due to the double offset design of HPBFVs, the differential pressure over the disc can cause sufficient torque to open the

valve spontaneously. For this reason, it is important not to remove lever or actuator from a valve that is or will be pressurized.

6.3 Lever operated valves should always be locked securely in desired throttle plate notch to prevent unexpected disc movement.

Installation, Operation and Maintenance Instructions

NIBCO 6822 and 7822 Series High Performance Butterfly Valves

FLANGE

SPECIFICATION

ASME/ANSI B16.1

CLASS 250 CAST IRON

ASME/ANSI B16.5

CLASS 300 STEEL

CAP SCREW LENGTHS ALLOWS

FOR 1/16” THICK FLANGE GASKETS

VAL

VE SIZE

VAL

VE BODY

THICKNESS

FLANGE

THICKNESS

RECOMMENDED

CAP SCREW

LENGTH

FLANGE

THICKNESS

RECOMMENDED

CAP SCREW

LENGTH

QUANTITY

OF

L:ONG

CAP

SCREWS

REQUIRED PER

VAL

VE

QUANTITY

OF

**

SHORT

CAP

SCREWS

REQUIRED PER

VAL

VE

CAP

SCREW

SIZE & THREAD

PITCH

2”

1.69

0.88

1.50

0.94

1.75

16

5/8”- 11 UNC

2½”

1.84

1.00

1.75

1.06

1.75

16

3/4”- 10 UNC

3”

1.88

1.13

2.00

1.19

2.00

16

3/4”- 10 UNC

4”

2.12

1.25

2.00

1.31

2.25

16

3/4”- 10 UNC

5”

2.31

1.38

2.50

1.44

2.50

16

3/4”- 10 UNC

6”

2.31

1.44

2.50

1.50

2.50

24

3/4”- 10 UNC

8”

2.88

1.63

3.00

1.69

3.00

24

7/8”- 9 UNC

10”

3.25

1.88

3.25

1.94

3.25

32

1”- 8 UNC

12”

3.62

2.00

3.50

2.06

3.50

24

*1-1/8”- 8 UN

3.00

3.00

8

14"

4.62

2.12

4.00

2.19

4.00

32

*1-1/8”- 8 UN

3.00

3.00

8

16"

5.25

2.25

4.50

2.38

4.50

32

*1-1/4”- 8 UN

3.25

3.25

8

18"

5.88

2.38

4.50

2.44

4.50

40

*1-1/4”- 8 UN

3.25

3.25

8

20"

6.30

2.50

4.50

2.56

4.50

40

*1-1/4”- 8 UN

3.50

3.50

8

24"

7.12

2.75

5.00

2.81

5.00

40

*1-1/2”- 8 UN

4.00

4.00

8

*SPECIAL PITCH CAP SCREW THREAD REQUIRED PER MSS SP-68 SPECIFICATIONS

**SHORT SCREWS REQUIRED FOR BLIND TAPPED HOLES NEAREST TO STEM FOR 12” & LARGER SIZE VALVES