Installation, Operation – DeVilbiss JGA-614FWH-186B User Manual

Page 6

6

© ITW Ltd 2001

Installation

Important: To ensure that this

equipment reaches you in first class

condition, protective coatings have

been used. Flush the equipment

through with a suitable solvent

before use.

1. Attach air hose to connector (13).

Recommended hose size 8 mm

bore. The air supply should be

filtered and regulated.

2. Attach the Cup Lid assembly (27)

to the Fluid Inlet connector (17).

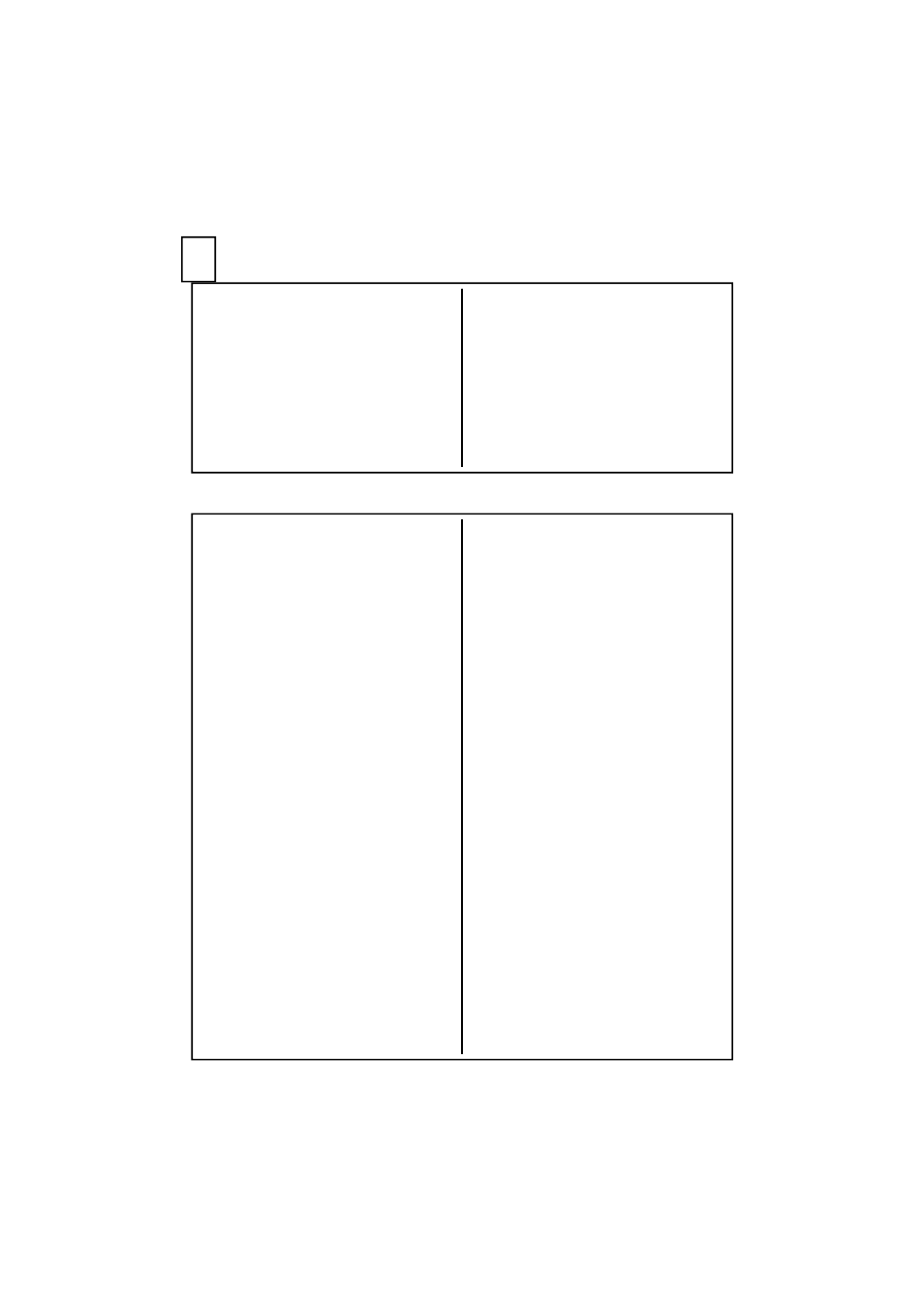

3. Position the Yoke at right angles

to the Gun with the Cam lever to

the front (see picture). Make sure

the vent hole in the lid is

positioned under the Yoke and

the hole in the diaphragm is 180°

to the Lid vent hole.

E

E

Operation

1. M i x c o a t i n g m a t e r i a l t o

manufacturers instructions.

2. Fill the cup with the required

amount of material. Fill to no more

than 25mm(1“) from the top of the

cup. DO NOT OVERFILL.

3. Attach Cup to the Lid assembly.

4. Turn needle adjusting screw (10)

on the spraygun clockwise to

prevent movement.

5. Turn pattern valve (5) counter-

clockwise to fully open

6. Adjust inlet air pressure to give

3.5 bar (50psi) at the gun inlet

with the gun triggered. (pressure

gauge attachment shown under

Accessories is recommended for

this).

7. Turn needle adjusting screw

counter clockwise until first thread

shows.

8. Test spray. If the finish is too dry

reduce airflow by reducing inlet

pressure. If finish is too wet

reduce fluid flow by turning needle

s c r e w ( 1 0 ) c l o ck w i s e . I f

atomisation is too coarse,

increase inlet air pressure. If too

fine reduce inlet pressure.

9. The pattern size can be reduced

by turning adjusting valve (5)

clockwise.

10. Hold gun perpendicular to surface

being sprayed. Arcing or tilting

may result in uneven coating.

11. The recommended spray distance

is 150-200 mm (6”-8”).

12. Spray edges first. Overlap each

stroke a minimum of 50%. Move

gun at a constant speed.

13.

Always turn off air supply and

relieve pressure when gun is not

in use.

Air Flow Valve (14)

1. If the airflow valve (14) is fitted

this can be used to reduce the

inlet pressure through the gun.

Screw the Adjusting Knob in to

reduce pressure.