Belt and pulley installation, Fig. 7 – belt & pulley tension, Wheel-to-inlet clearance/overlap – MK Plastics RBK IO&M User Manual

Page 4

Wheel-to-Inlet Clearance/Overlap

The correct wheel-to-inlet clearance/overlap is critical to proper fan performance. This clearance should be verified before initial

start-up since rough handling during shipment could cause a shift in fan components. Refer to Fig. 6.

4

Gap

Gap

Gap

Gap

Fan Size

Gap/Overlap

12

5/8"

15

11/16"

18

1"

24

1"

30

1-1/16"

36

1-1/16"

40

1-9/16"

Fig. 6 – Wheel/Inlet Clearance

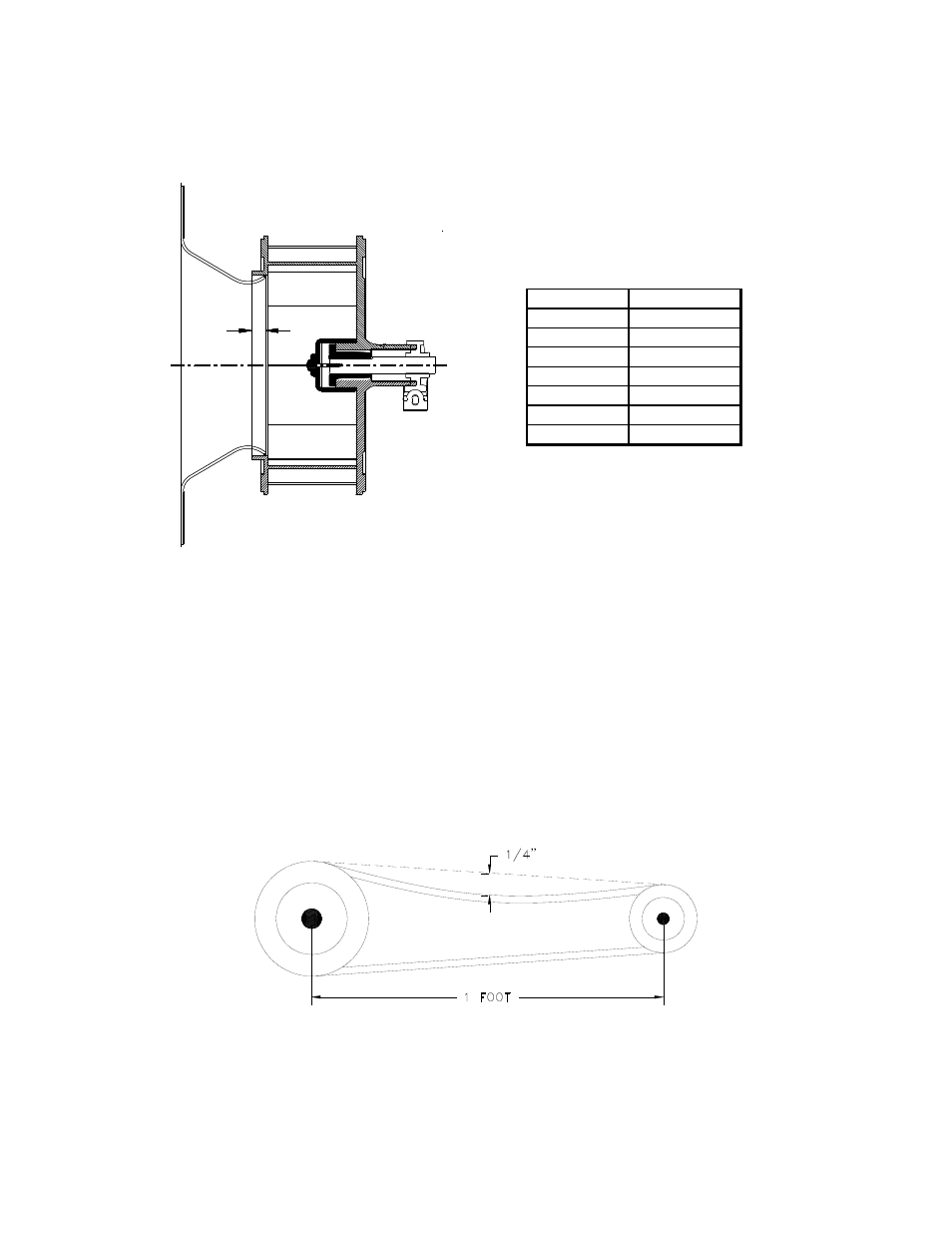

Belt and Pulley Installation

Belt tension is determined by the sound the belts make when the fan is first started. Belts will produce a loud squeal, which

dissipates after the fan is operating at full capacity. If the belt tension is too tight or too loose, lost efficiency and possible

damage can occur. Do not change the pulley pitch diameter to change tension. This will result in a different fan speed than

desired.

1. Loosen motor plate adjustment nuts and move the motor plate in order that the belts can easily slip into the grooves on

the pulleys. Never pry, roll, or force the belts over the rim of the pulley.

2. Slide the motor plate back until proper tension is reached. For proper tension a deflection of approximately ¼” per foot

of center distance should be obtained by firmly pressing the belt. Refer to Fig. 7.

3. Lock the motor plate adjustment nuts in place.

4. Ensure pulleys are properly aligned. Refer to Fig. 8

Fig. 7 – Belt & Pulley Tension