MK Plastics DHK-NW IO&M User Manual

Page 2

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com

Page. 2

Pre-Installation

When the unit is removed from storage after a long duration,

all bearing grease should be purged and replenished with

fresh grease as per the lubrication decal. The motor should be

measured to verify that the resistance is still at a satisfactory

level compared to the value recorded prior to storage.

Inlet & Outlet Fan Installation

Efficient fan performance relies on the proper installation

of inlet and discharge ducts. Installations with poor inlet or

discharge configurations may result in reduced performance.

Restricted or unstable flow at the fan inlet can cause pre

rotation of incoming air or uneven loading of the fan wheel

resulting in increased system losses and sound levels.

Free discharge or turbulent flow in the discharge ductwork

will also result in system losses. Make sure the following

recommendations are followed.

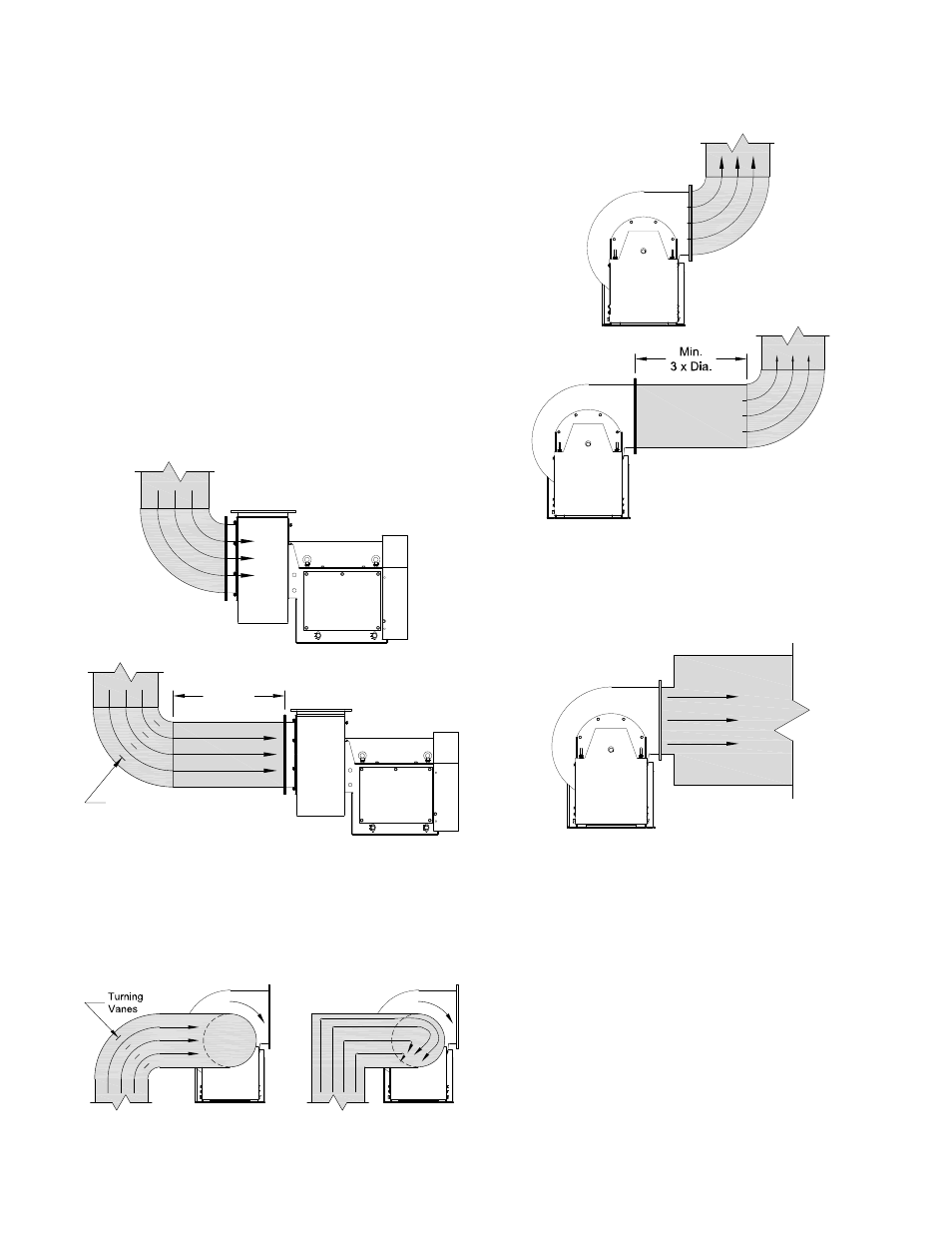

Inlet Duct Turns

Installation of a duct turn or elbow too close to the fan inlet

reduces fan performance. To achieve full fan performance,

there should be at least three effective wheel diameters

between duct turns or elbows and the fan inlet.

Inlet Spin

A common cause of reduced fan performance is inlet spin. To

prevent this occurring, it is good practice to use turning vanes

in the duct to reduce the effects.

Discharge Duct Turns

Where possible, allow minimum three duct diameters between

turns or elbows and fan outlet. Fan performance is reduced

when turns are made immediately off the fan discharge.

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost efficiency because it doesn’t allow for a static regain.

Fan Installation

Follow proper handling instructions given earlier.

•

Move the fan to the final mounting position.

•

Remove skid, crates, and packing materials carefully.

•

If supplied, place vibration pads or isolation base on

mounting bolts. Line up holes in fan base with bolts.

•

Place fan on mounting structure. Carefully level utilizing

shims as required at all mounting hole locations. Bolt

down the unit.

•

Any grout may now be used. Bolt the fan in position

before applying grout. Do not depend upon grout to

support rotating equipment.

•

Continue with Operations Checklist.

Additional instructions may be given for some fan sizes,

components and accessories in the submittal.

Turning Vanes

Min.

3 x Dia.

Figure 2 - Inlet Ducting

Good

Poor

Figure 3 - Inlet Spin

Good

Poor

Poor

Good

Figure 4 - Outlet Ducting

Figure 5 - Free Discharge