Lp15 operators manual final en 19, Maintenance, Lehr – LEHR 15 HP 4-STROKE User Manual

Page 19: Adjusting idling speed, Changing engine oil

LEHR

|

ALL RIGHTS RESERVED

17

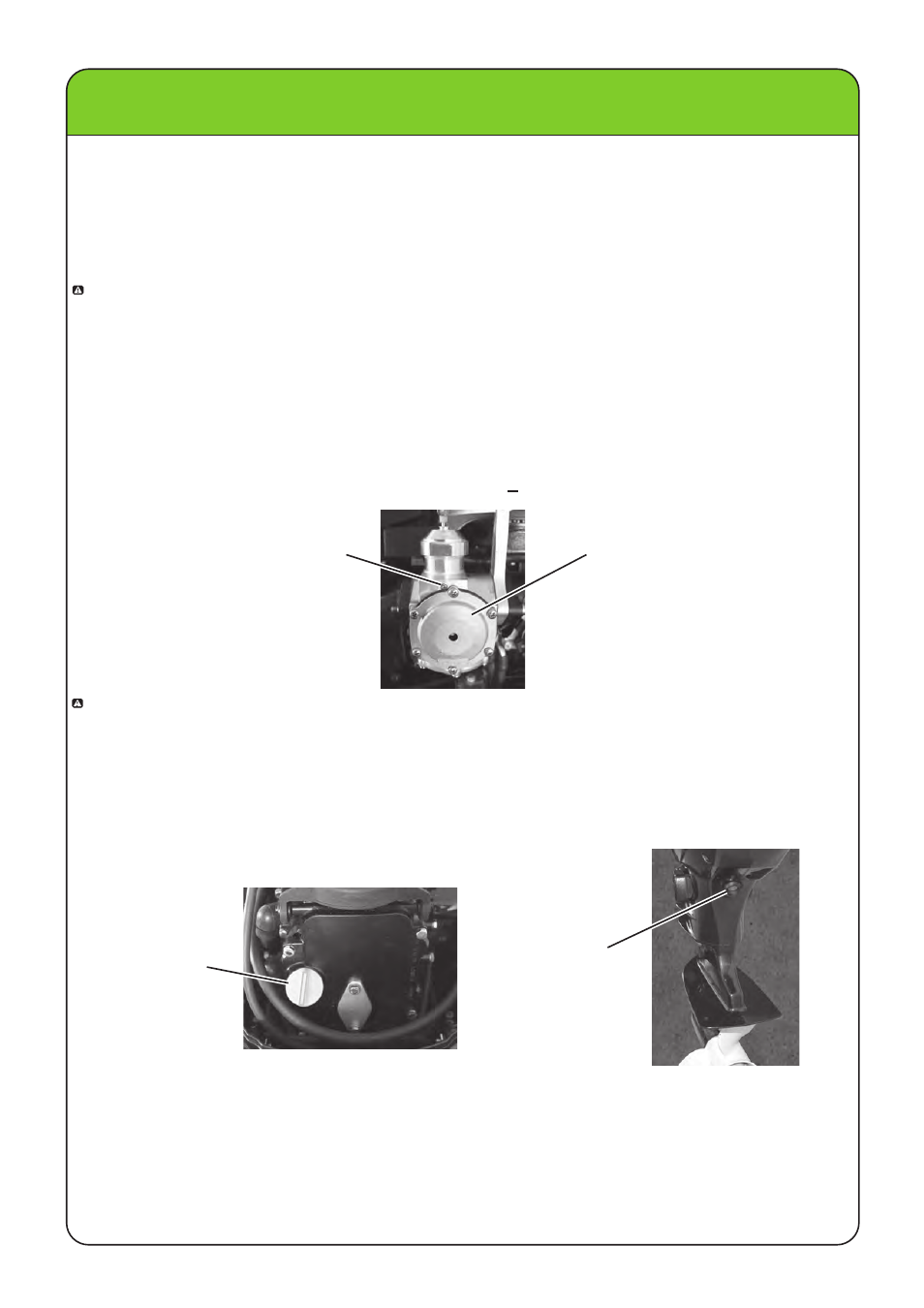

ADJUSTING IDLING SPEED

WARNING: Do not touch or remove electrical parts when starting or during operation. Keep hands, hair, and

clothes away from the flywheel and other rotating parts while the engine is running.

CAUTION: This procedure must be performed while the outboard motor is in the water. A flushing attachment

or test tank can be used.

NOTE: A diagnostic tachometer should be used for this procedure. Results may vary depending on whether

testing is conducted with the flushing attachment, in a test tank, or with the outboard motor in the

water.

1. Start the engine and allow it to warm up fully in neutral until it is running smoothly.

NOTE: Correct idling speed inspection is only possible if the engine is fully warmed up. If not warmed up

fully, the idle speed will measure higher than normal. If you have difficulty verifying the idle speed,

or the idle speed requires adjustment, consult a LEHR dealer or other qualified mechanic.

2. Verify whether the idle speed is set to specification (1050 + 150 RPM). Adjust the speed by turning the

idle speed screw with a phillips head screw driver.

CHANGING ENGINE OIL

WARNING: Avoid draining the engine oil immediately after stopping the engine. The oil is hot and should

be handled with care to avoid burns.

• Be sure the outboard motor is securely fastened to the transom or a stable stand.

• Do not overfill the oil, and be sure the outboard motor is upright (not tilted) when checking and changing

the engine oil.

• If the oil level is above the upper level mark, drain until the level meets the specified capacity. Overfilling

the oil could cause leakage or damage.

• Change the engine oil after the first 10 hours of operation, and every 100 hours or at 6 month intervals

thereafter. Otherwise the engine will wear quickly.

NOTE: Change the engine oil when the oil is still warm.

1. Put the outboard motor in an upright position (not tilted).

2. Remove the oil fill cap.

3. Prepare a suitable container that holds a larger amount than the engine oil capacity. Loosen and remove

the drain plug while holding the container under the drain hole. The oil drain plug is located on the

tiller side of the engine. Use a 14 mm socket wrench. Then remove the oil fill cap. Let the oil drain

completely. Wipe up any spilled oil immediately.

4. Put a new gasket on the oil drain plug. Apply a light coat of oil to the gasket and install the drain screw.

NOTE: If a torque wrench is not available when you are installing the drain screw, finger tighten the screw

just until the gasket comes in contact with the surface of the drain hole. Then tighten 1/4 to 1/2 turn

more. Tighten the drain screw to the correct torque with a torque wrench as soon as possible.

5. Add the correct amount of oil through the filler hole. Install the oil fill cap.

MAINTENANCE

IDLE SPEED SCREW

CARBURETOR

OIL DRAIN PLUG

TORQUE TO 13.3 ft-lb (18 N-m)

NOTE: Inspect the following for any source of a fuel leak. A propane sniffing device may be used to inspect.

• Fuel system parts leakage

• Fuel line joint leakage

• Fuel line cracks or other damage

• Fuel connector leakage

OIL FILL CAP

(REAR VIEW OF ENGINE)