Oil change procedure – Labconco VACUUBRAND HYBRID Rotary Vane Pump 7584000 User Manual

Page 33

Under normal operating conditions:

- Check oil level every time before starting the pump.

- Carry out an oil change once aging of the oil is indi-

cated by darker color compared to new oil.

- Carry out oil changes at least once a year.

- Dispose of the used oil, which may be contaminated,

according to all applicable regulations.

If the oil contains small quantities of water/solvent:

+

The oil can be cleaned to a certain extent by operating

the pump for 1 - 2 hours with the inlet line sealed and

the gas ballast valve open.

Oil change procedure

+

Carry out the oil change only after the pump has reached

its normal operating temperature.

➨

Switch off the pump and isolate it from its application.

Ventilate the pump to atmospheric pressure. Discon-

nect the electrical power cord. To vent the oil reservoir,

remove the manometer with its adapter carefully (open

end wrench width 17 mm). Pay attention to the O-ring!

Do not turn the manometer itself as leaks might be

caused!

+

Choose a suitable pad; oil may drip. Use a suitable

container to catch the oil.

➨

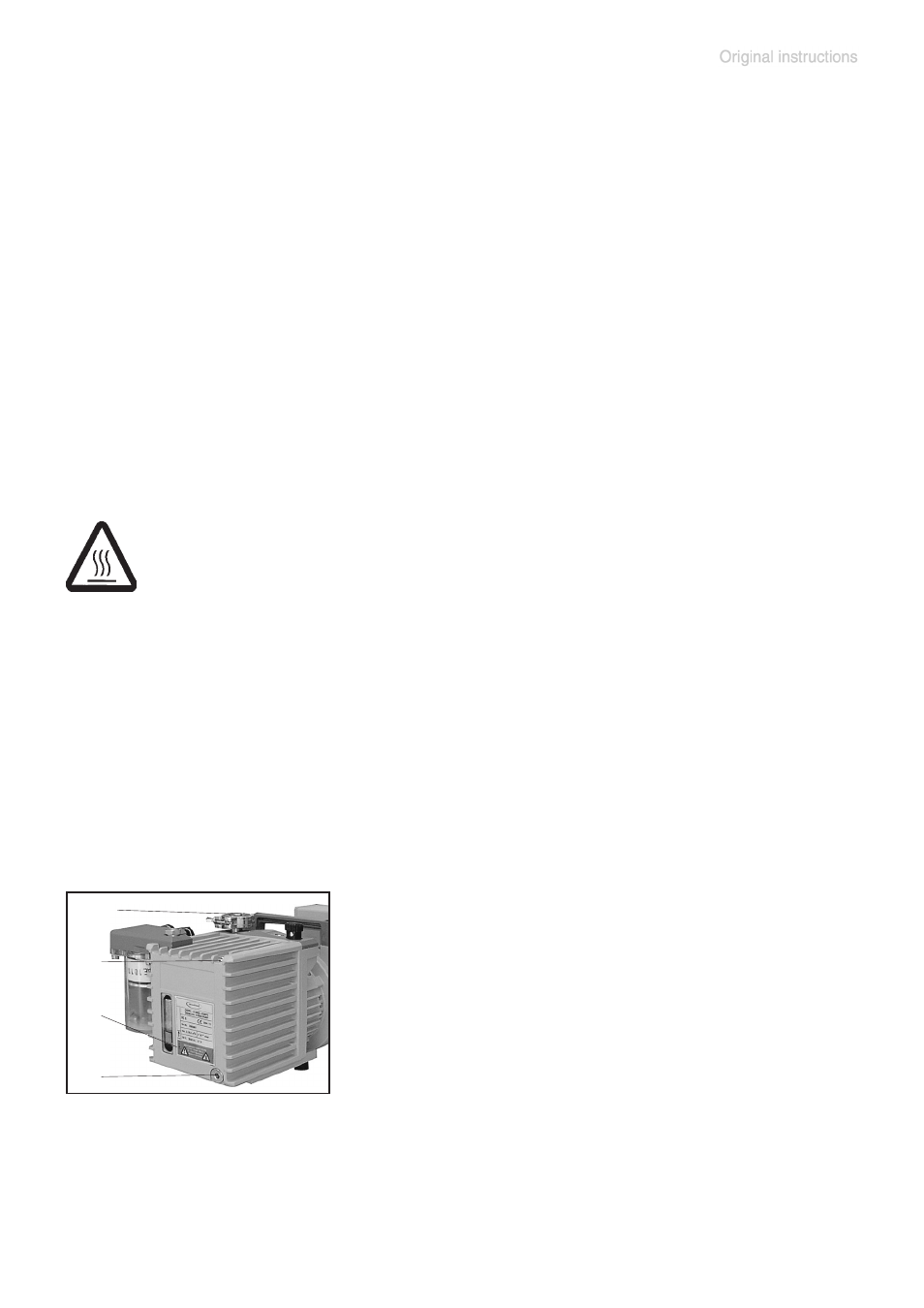

Place a suitable container below the oil outlet

(9).

➨

Remove the oil drain plug (9) below the rat-

ing plate, paying attention to the O-ring.

➨

Tilt the pump slightly and catch the oil in a

suitable container.

+

Dispose of the used oil according to regula-

tions.

➨

Screw in oil drain plug (9) with O-ring.

➨

Screw in manometer with O-ring.

➨

To flush the pump, pour in fresh oil (approx. 0.05 quarts

(50 ml)) through the pump inlet (1) (remove separator if

necessary).

(8)

(9)

(1)

(10)