Hanna Instruments BL 932700 User Manual

Page 2

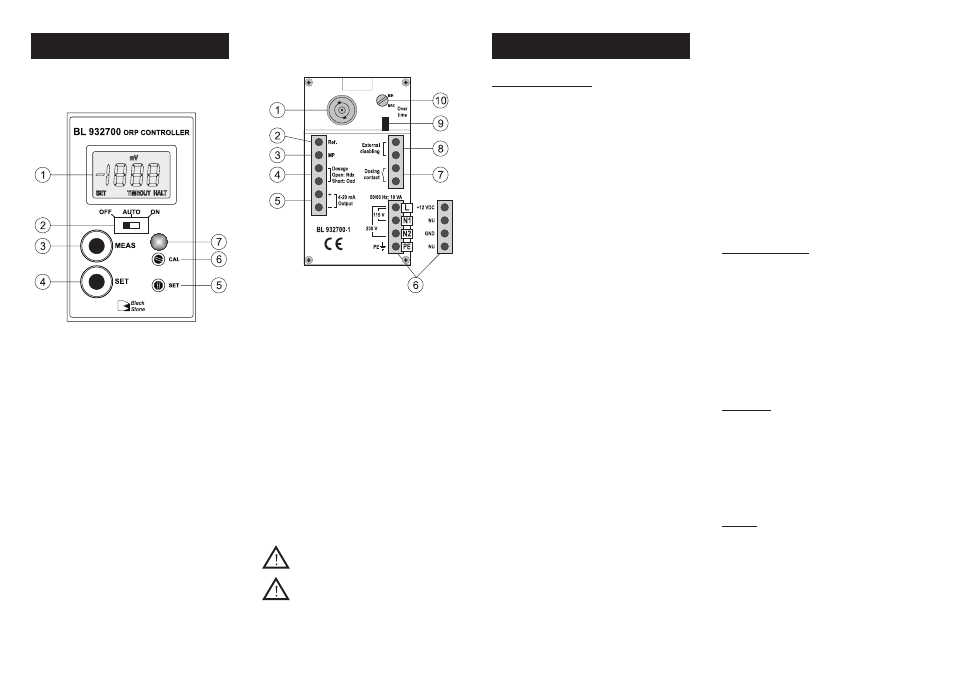

REAR PANEL CONNECTIONS

Terminals #1, #2 and #3: Electrode

• Connect an ORP electrode to the meter BNC plug (#1).

• To benefit from the differential input, connect the proper

electrode wire (if available) or a cable with a potential

matching pin (grounding bar) to the relevant terminal

(#3) on the rear panel.

Note: When the Matching Pin can not be immersed together

with the electrode in the solution, disable the differential

input by shorting terminals #3 (Matching Pin) and

#2 (Electrode Reference) with a jumper wire.

Terminals #4: Dosing selection

• For Rdx dosage, leave the circuit open.

• For Oxd dosage, short the terminals with a jumper wire.

Terminals #5: 4-20 mA Output

• These output terminals are used for connecting a recorder.

The output is from 4 to 20 mA and is proportional to the

measured ORP value.

Terminals #6: Power Supply

• Model BL932700-0: connect the 2 wires of a 12 Vdc

power adapter to the terminals +12 Vdc and GND.

• Model BL932700-1: connect a 3-wire power cable to the

terminals while paying attention to the correct earth (PE),

line (L) and neutral (N1 for 115 V or N2 for 230 V) contacts.

Terminals #7: Dosing Contact

• This contact drives the dosing system, accordingly to the

selected setpoint and dosing direction:

• if “Rdx” dosage is set, the relay is ON and dosing

activated if measured value is higher than setpoint;

• if “Oxd” dosage is set, the relay is ON and dosing

activated if measured value is lower than setpoint.

Note: The setpoint has a typical hysteresis value comparable

to the meter accuracy.

Terminals #8: External Disabling Contact

• This is a normally open contact and can be used for

example for connecting a level controller.

• When the contact is closed, any dosing action stops, the

LED indicator on the front panel will blink Red and the

LCD will show the “HALT” warning message.

Note: If the OFF/Auto/ON switch is in ON position, the

dosing action will not stop, even if the external

disablig contact is closed. Dosage will proceed, the LED

FUNCTIONAL DESCRIPTION

Front panel

Rear panel

1. Liquid Crystal Display

2. Switch for selecting dosing mode:

• OFF = dosing disabled

• Auto = automatic dosage, depending on setpoint value

and dosing selection

• ON = dosing always active

3. “MEAS” key to set the instrument to measurement mode

4. “SET” key to display and set the setpoint value

5. “SET” trimmer to adjust the setpoint value (within ±1000mV)

6. “CAL” trimmer

7. 3-colour LED indicator:

• Green = meter in measurement mode

• Orange/Yellow = dosing in progress

• Red, blinking = indicates an alarm condition

OPERATIONS

indicator will lit Orange/Yellow and the LCD will show

the “HALT” warning message.

Overtime system: jumper (#9) and trimmer (#10)

• This system allows the user to set a maximum dosing

period, by adjusting the rear trimmer from 5 (min) to

approx. 30 (max) minutes.

• When the set time is exceeded, any dosing action stops,

the LED indicator on the front panel will blink Red and the

LCD will show the “TIMEOUT” warning message. To exit

the overtime condition, set the OFF/Auto/ON switch to

“OFF” position, and then to “Auto” again.

• For disabling the overtime feature, simply remove the

jumper on the rear panel.

Note: The overtime system works only if the OFF/Auto/ON

switch is in “Auto” position.

OPERATING THE METER

Before proceeding make sure that:

• the setpoint value has been properly adjusted;

• all rear panel wiring and selections are correct;

• the Auto/OFF/ON switch is in the desired position.

Install or immerse the electrode in the solution to be moni-

tored, then press the “MEAS” key (if necessary).

The LCD will show the ORP (mV) value. The LED indicator will

light up Green when the meter is in measurement mode and

dosing is not active, while will light up Orange/Yellow for

signaling that a dosing action is in progress.

CALIBRATION

This meter is factory calibrated. Anyway, it is possible to check

the calibration as follows:

• ensure the meter is in measurement mode;

• immerse electrode and Matching Pin (if used) in one of the

available ORP test solutions (see “Accessories”);

• shake briefly and wait for reading to stabilize;

• if necessary, adjust reading through the “CAL” trimmer.

SETPOINT

Press the “SET” key: the display will show the default or

previously adjusted value, together with the “SET” indication.

Using a small screwdriver adjust the “SET” trimmer until the

desired setpoint value is displayed.

After 1 minute the meter automatically returns to the normal

mode; or press the “MEAS” key.

ISTBL2700R2 04/05

All external cables connected to the rear panel

should end with cable lugs.

A circuit breaker (rated 6A max.) must be

connected in close proximity to the equip-

ment, and in a position easy to reach by the

operator, for disconnection of the instrument

and of all the devices connected to the relays.

1. BNC plug for ORP electrode

2. Connection for electrode reference

3. Connection for potential Matching Pin

4. Rdx/Oxd dosage selection terminal:

• contact open = reductant selection

• contact closed = oxidant selection

5. 4-20 mA output terminal for recorder connection

6. Power supply terminal:

• for BL932700-0 model: 12 Vdc adapter

• for BL932700-1 model: 115 Vac or 230 Vac option

7. This contact acts as a switch for driving the dosing system (e.g.

dosing pump)

8. External control and disabling of dosing system

9. Jumper for enabling (jumper in) or disabling (jumper

removed) the overtime control

10. Trimmer for overtime setting (typically from 5 to 30 minutes)