Natural gas (g20) to lpg (g31) conversion, G31 burner % co, 9 lpg conversion - all models – Glow-worm Ultracom cxi User Manual

Page 41

41

MODEL

G31 BURNER % CO

2

CHECK

(case on)

SETTING

(case off)

9.2 to 10.2

10.0 to 11.0

9.2 to 10.2

0.004

0.004

0.004

10.0

10.5

9.8

+ 0.0

- 0.9

+ 0.3

- 0.7

+ 0.2

- 0.8

Throttle

TURNS

24cxi

30cxi

38cxi

CO/CO2

12.9 LPG CONVERSION - all models

As an option, a chargeable boiler only commissioning service

can be provided by Glow-worm Service by calling telephone

No. 01773 828100.

NOTE: Steps 12.1 and 12.3 will need to be completed before

the appliance can be converted.

This conversion should only be carried out by a

competent

person approved at the time by the Health and Safety

Executive.

During the conversion to Propane use of a suitable flue gas

analyser is necessary.

● The person carrying out a combustion measurement should

have been assessed as competent in the use of a flue gas

analyser and the interpretation of the results.

● The flue gas analyser used should be one meeting the

requirements of BS7927 or BS-EN50379-3 and be calibrated in

accordance with the analyser manufacturers’ requirements.

● Competence can be demonstrated by satisfactory comple-

tion of the CPA1 ACS assessment, which covers the use of

electronic portable combustion gas analysers in accordance

with BS 7967, parts 1 to 4.

Tools required to make the conversion are a 2mm Allen key

and an electricians screwdriver.

Having checked :

● the appliance and system have been installed in

accordance with the instructions.

● the integrity of the flue system and flue seals....

● the integrity of the appliance combustion circuit and

relevant seals....

● that all internal/external controls are calling for heat.

● the gas service isolation valve ‘F’, diagram 12.2, is open

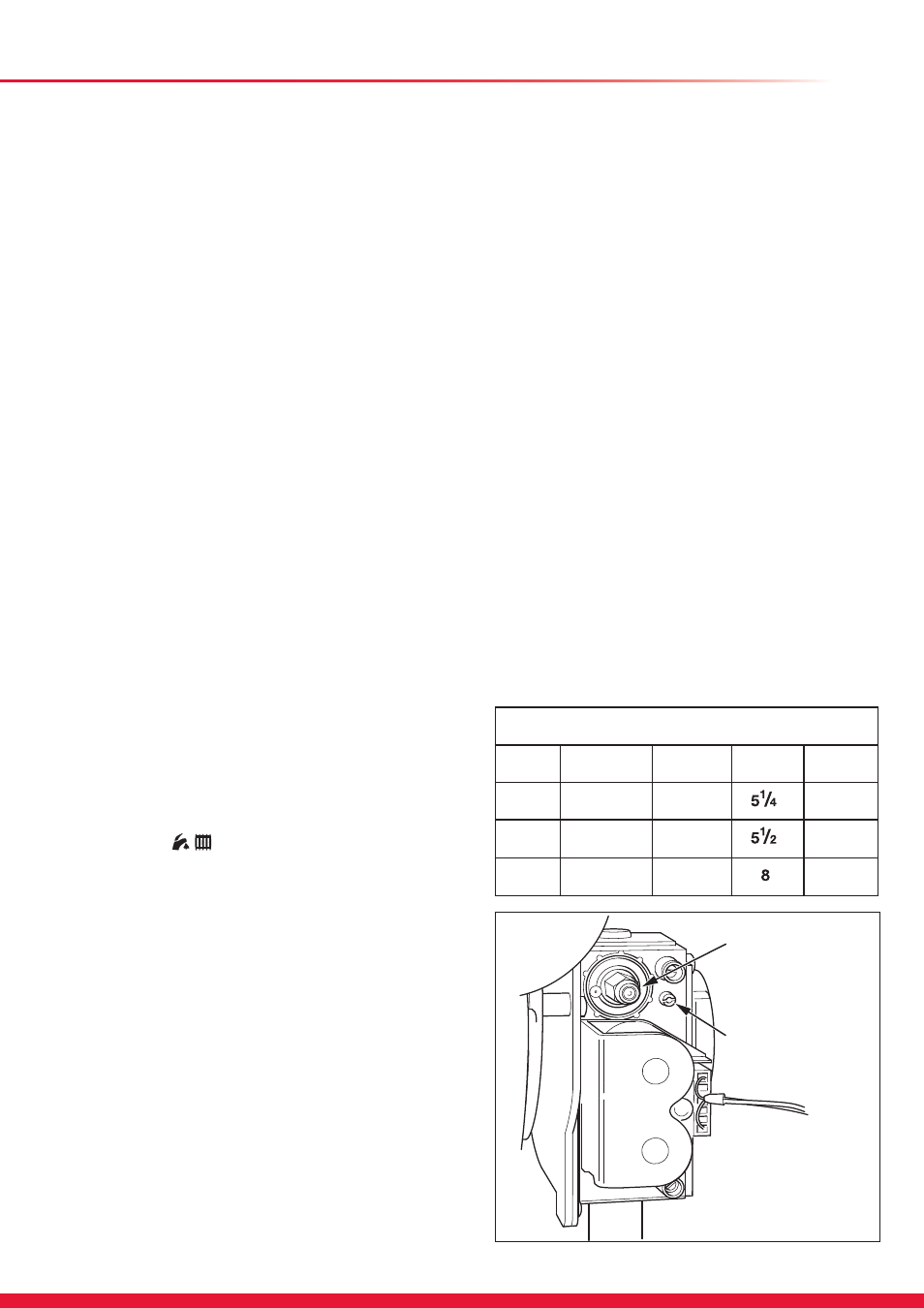

(1) Gain access the gas valve, by removing the front and

inner casing panels, see diagram 13.2.

(2) Refer to diagram 12.5 and turn the gas valve throttle fully

clockwise.

(3) Turn the throttle anti-clockwise by the number of turns

shown in the table.

(4) Ensure that the gas analyser is set to the correct fuel

setting - Propane.

(5) Attach combustion analyser to the combustion test point,

refer diagram 13.1.

IMPORTANT: Remember to replace the cap on

completion of the test.

(6) Select the “

”, constant central heating with DHW

function by pressing the “Mode” button repeatedly. The

boiler should fire automatically.

The appliance will enter a self checking routine, then the

fan will start and the ignition sequence commence.

The boiler, if necessary, will automatically repeat the

ignition sequence a further 4 times.

If the burner fails to ignite the display will show “F1”.

Initially this may be due to air in the gas supply line.

Depress the ‘reset’ button on the fascia to clear the

display and the ignition sequence will be repeated.

If the appliance still does not light & goes “F1”, turn the

throttle anti-clockwise a further turn and press the reset

button. The appliance will (after a short delay) again

attempt to fire. Repeat this procedure, up to a total of 2

extra turns on the throttle screw, until the appliance lights.

(7) Check and adjust the burner %CO

2

at maximum rate.

Press the “reset” button on the controls fascia, release

and immediately press and hold in the “+” button. After

approximately 5 seconds “Hi” will be displayed. Pressing

the mode button when “Hi” is selected will force the boiler

to maximum rate, the display will flash between “Hi” and

the “default display” this will indicate the boiler has been

forced to maximum.

Natural Gas (G20) to LPG (G31) Conversion

15440

Diagram 12.5

(8) If necessary, adjust the burner % CO

2

to the value shown

in the “SETTING” column of the table, by turning the

throttle screw (anti-clockwise to increase), see diagram

12.5 no more than 1/8 of a turn, waiting a minute to allow

for the appliance to stabilise before checking or making

further adjustments.

(9) Exit the check sequences press the “mode” and “+”

buttons simultaneously, this will reset the boiler to the

default display.

(10) Check the burner % CO

2

, at minimum rate, to the value

shown in the “SETTING” column of the table.

(11) If adjustment is required, press the “reset” button on the

controls fascia, release and immediately press and hold

in the “+” button. After approximately 5 seconds “Hi” will

be displayed. Pressing the “+” or “-” buttons will cycle

between “Hi” and “Lo”. Pressing the mode button when

“Lo” is selected will force the boiler to minimum rate, the

display will flash between “Lo” and the “default display”

this will indicate the boiler has been forced to minimum.

(12) Adjustment of the %CO

2

is very coarse so carefully

adjust the %CO

2

to the value shown in the “SETTING”

column of the table with the offset adjustment, see

diagram 12.5 (Rotate clockwise to increase).

(13) To exit the function press the “mode” and “+” buttons

simultaneously, this will reset the boiler to the default

display.

(14) Repeat (8) and check CO

2

at maximum rate - adjust if

necessary. Check that the CO/CO

2

ratio is less than the

value in the table below.

(15) Remove analyser probe from the test point and replace

the cap. Replace the control box and the inner and front

panels.

(16)

IMPORTANT: Fit the LPG conversion label supplied

in the documentation pack to the inner front panel

alongside the data label. Refit the inner door and

outer door.

(17) Complete the commissioning, refer to section 12.5 .

13869

OFFSET

ADJUSTMENT

SCREW

THROTTLE