Maintenance, 1 annual maintenance, 2 casing removing – Glow-worm Easicom User Manual

Page 35

0020140413_01 - 09/12 - Glow-worm

• To obtain service, please call your installer or Glow-worm’s

own service organisation.

PLEASE NOTE: During routine servicing, and after any

maintenance, we recommend that the following must be checked:

- The integrity of the flue system and the flue seals,

- The integrity of the boiler combustion circuit and the relevant

seals,

- The operational (working) gas inlet pressure at maximum rate,

- The gas rate,

- The combustion performance.

• See the "Safety instructions" chapter for a list of operations to

be performed prior to the maintenance of the application.

• Once the maintenance operations have been completed,

consult the ¨Start Up¨ chapter to restart the appliance.

17.1 Annual Maintenance

17.1.1

Verification of components

• Check that the flow sensor is working properly.

See chapter "Specific adjustment > Appliance technical

settings and parameter list > Installation settings" and use

code “d.36”.

• Check that the fan is working properly.

See chapter "Specific adjustment > Appliance technical

settings and parameter list > Installation settings" and use

code “d.34”.

• Check that the temperature sensors are working properly.

See chapter "Specific adjustment > Appliance technical

settings and parameter list > Installation settings" and use

code “d.3, d.4, d.40, d.41”.

• Check the ionisation quality.

• Check that the thermal fuse protects the appliance against dry

fire. Disconnect the thermal fuse and check if "F76" fault code

is displayed on the screen.

• Check that the pressure sensor is working properly. The

pressure must be displayed on the screen.

• Check the pressure of the expansion vessel.

17.1.2

Other checks

• Check the CO

2

rate in the fuel and compare with the values

indicated in the chapter "CO

2

Measurement".

• Check that there are no leaks in the joints and the safety

valves.

• Check that there are no gas leaks.

• Verify that the flue system is sound and complete.

• Check the appliance’s electrical safety.

17.1.3

Cleaning of the components

• Clean the following components:

- The condensate trap

- The heat exchanger.

- The burner

- The fan

17.1.4

Corrosion and anti-sludge protection

In order to avoid corrosion, the addition of a corrosion inhibiter to

the heating circuit water is recommended. The inhibiter will stop

electrolytic reaction and bacterial growth between the different

metals used in the installation.

It will also avoid the formation of gas which could be produced

following the chemical reactions.

It is especially important to treat the water in underfloor heating

systems, as low temperatures favour bacterial growth. This can

lead to the formation of sludge, which in turn may block some or

all of the circuits.

In order to add the correct dosage of these products, you must

know the volume of water contained in the installation. It is

recommended that you note down the volume for future needs.

The inhibitors must be compatible with the materials employed in

the installation.

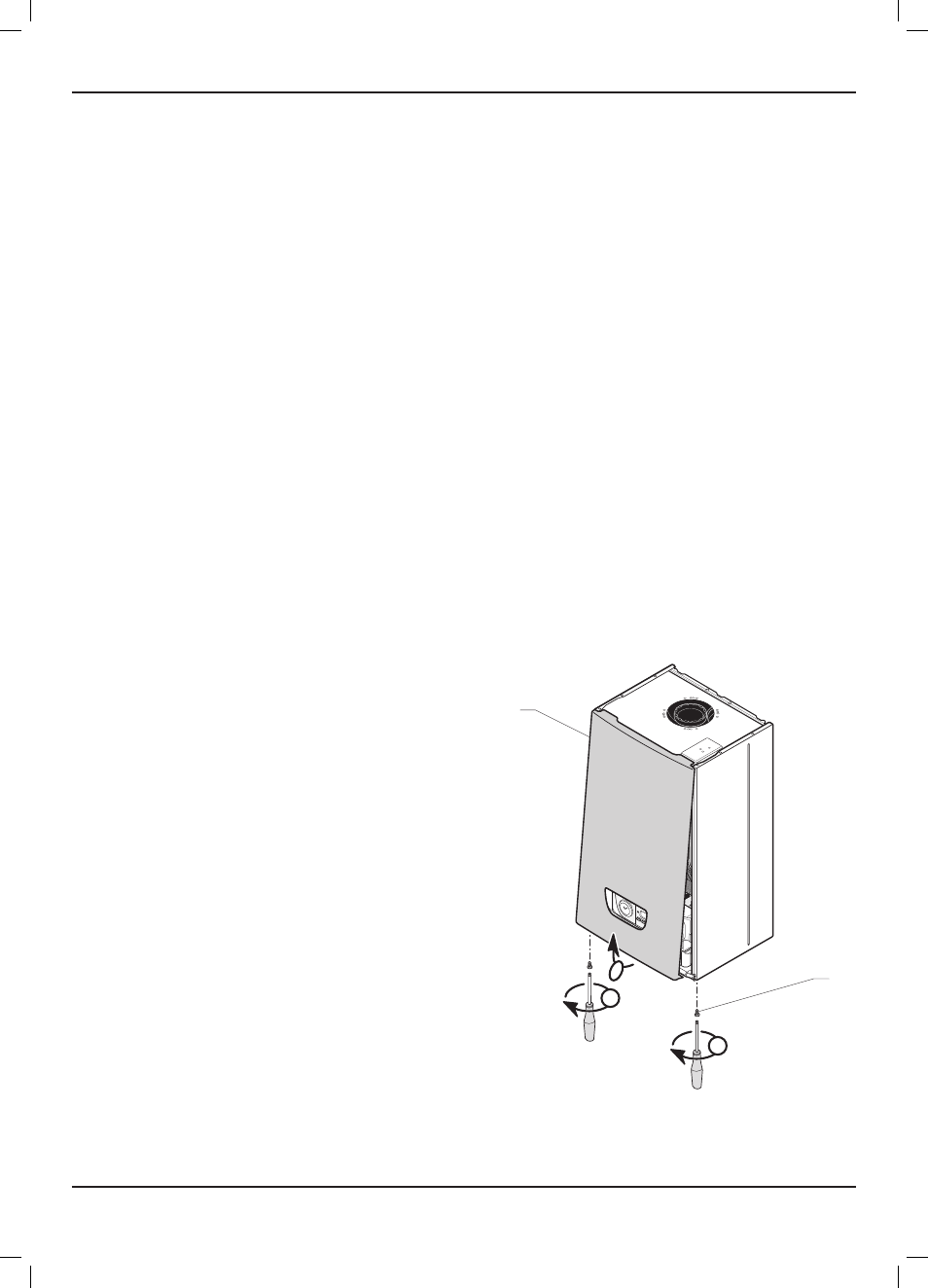

17.2 Casing removing

17.2.1

front panel

24

V

230

V

2

1

A

A

B

Key

1 front panel

2 Front panel retaining screw

• Undo the two screws (2) on the underside of the front panel

and remove the front panel (1).

MAINTENANCE

- 33 -