0 maintenance – ENMET ISA-M User Manual

Page 13

ISA – M

ENMET Corporation

11

7.0 Maintenance

7.0 Maintenance

The ISA – M gas monitor is a safety instrument and requires periodic testing and calibration at regular intervals. In

addition, check for obvious mechanical damage or malfunctions such as burned out lamps. On units requiring purging,

purge the sensor periodically. This interval varies with the amount of contaminants in the atmosphere.

4.1 Basic Troubleshooting

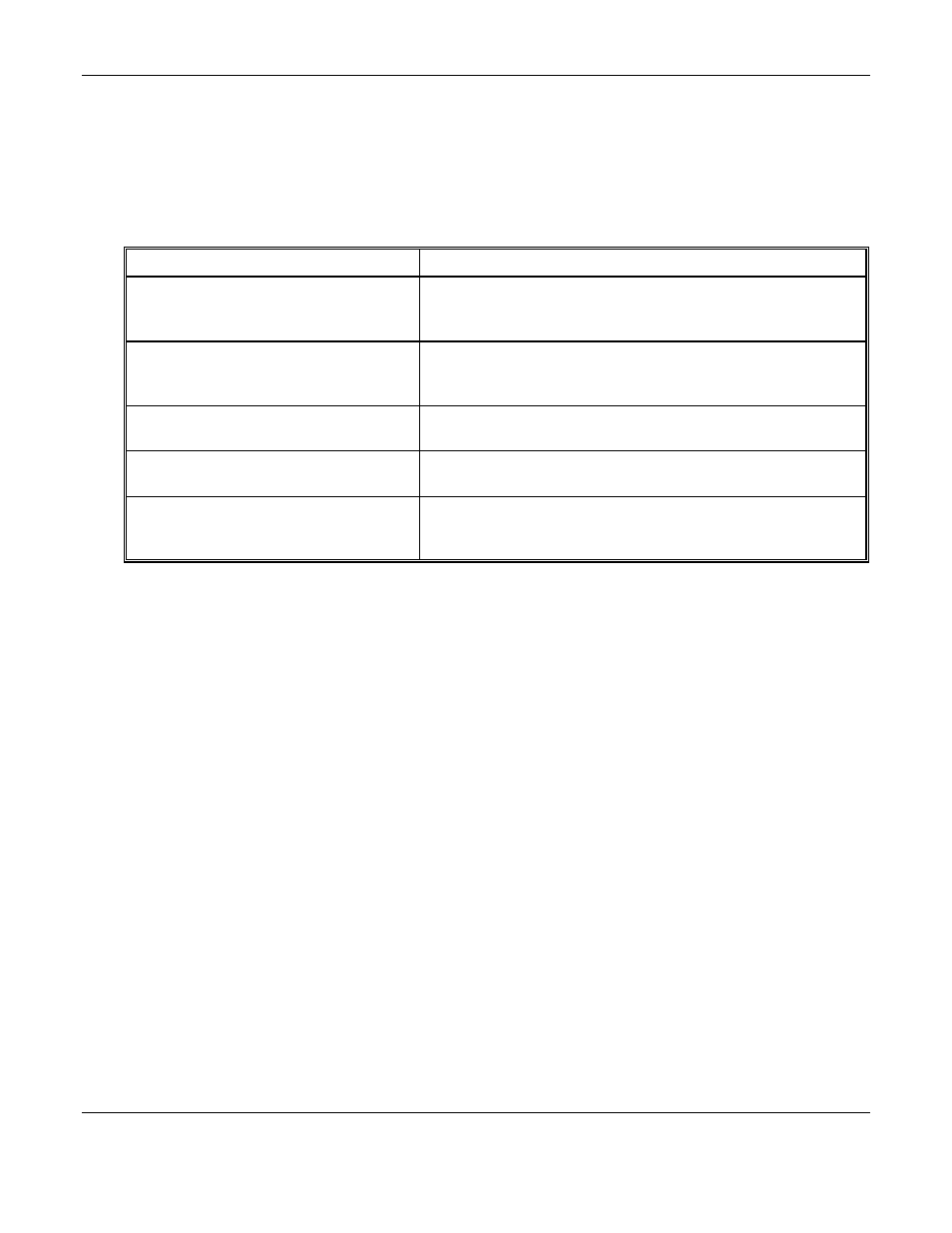

Symptom

Problem/Correction

When first plugged in, the unit alarms for

up to 10 - 20 minutes.

If the unit has not been used recently, this is normal. The MOS

sensor is cold and/or contaminated. Keep unit ON or PURGE (on

units so equipped) overnight with the sensor in fresh air.

Red alarm light stays on continuously, even

after allowed to operate (or PURGED)

overnight.

Either hazardous gas conditions exist, or there is a contaminated

sensor, or a bad circuit. Contact ENMET for voltage checks.

Either green or amber or red lights do not

work.

There might be a burned out lamp.

Unit fails to alarm when calibration gas is

applied.

Recalibration may be necessary. See section 6.0 If recalibration

fails, check sensor voltage, cylinder contents and pressure.

Unit gradually creeps into alarm or

sensitive.

Either hazardous gas conditions exist, or too recalibration is

necessary. On units requiring purging, rotate to PURGE once a

week for one hour to clean sensor surface.

7.2 Sensor Replacement

The MOS sensor is durable, it can be purged of contaminants by operating in PURGE for a sufficient length of time

and at regular intervals.

Gross contamination usually occurs during unavoidable misuse. Close exposure to an open gas flame, dipping the

sensor in a hydrocarbon such as lacquer, or continuous exposure to heavy concentrations of industrial vapors will

grossly contaminate a sensor. A grossly contaminated sensor causes a continuous alarm.

If a sensor is bad, replace it.

P

ROCEDURE

:

1. Obtain a new sensor assembly. Make sure the sensor type is identical to your original sensor (019, 030, 812, 813

or 109).

2. Disconnect the orange, brown and blue sensor wires.

3. Unscrew the assembly from the sensor enclosure.

4. Replace the bad sensor and reconnect the wires.

5. Set the sensor heater voltage (See Section 4.4).

6. Recalibrate the instrument (See Section 6.0).