Warning – EarthQuake 3310V User Manual

Page 11

Check for parts online at

www.getearthquake.com or call 800-345-6007 M-F 8-5

11

Operator's Manual

Front Tine Tiller 3310V

ChECk BELT TENSION

Belt tension may decrease over time. It must be adjusted within the first half

hour of operation, and checked after every two hours of operation. Proper

adjustment will assure long belt life. Too much or too little belt tension will

cause premature belt failure. To check and adjust the forward belt tension:

1. Turn off engine. Engine must be cool.

2. Remove spark plug wire from spark plug and secure.

3. With drive safety control lever in the neutral position, measure

length of spring when in its relaxed state.

4. Pull down on drive safety control lever and measure length of spring

when compressed. Ideal length would be 1/4” shorter. SEE FIGURE 5.

ChaNGE FORWaRD BELT

1. Turn off engine. Engine must be cool.

2. Remove spark plug wire from spark plug and secure.

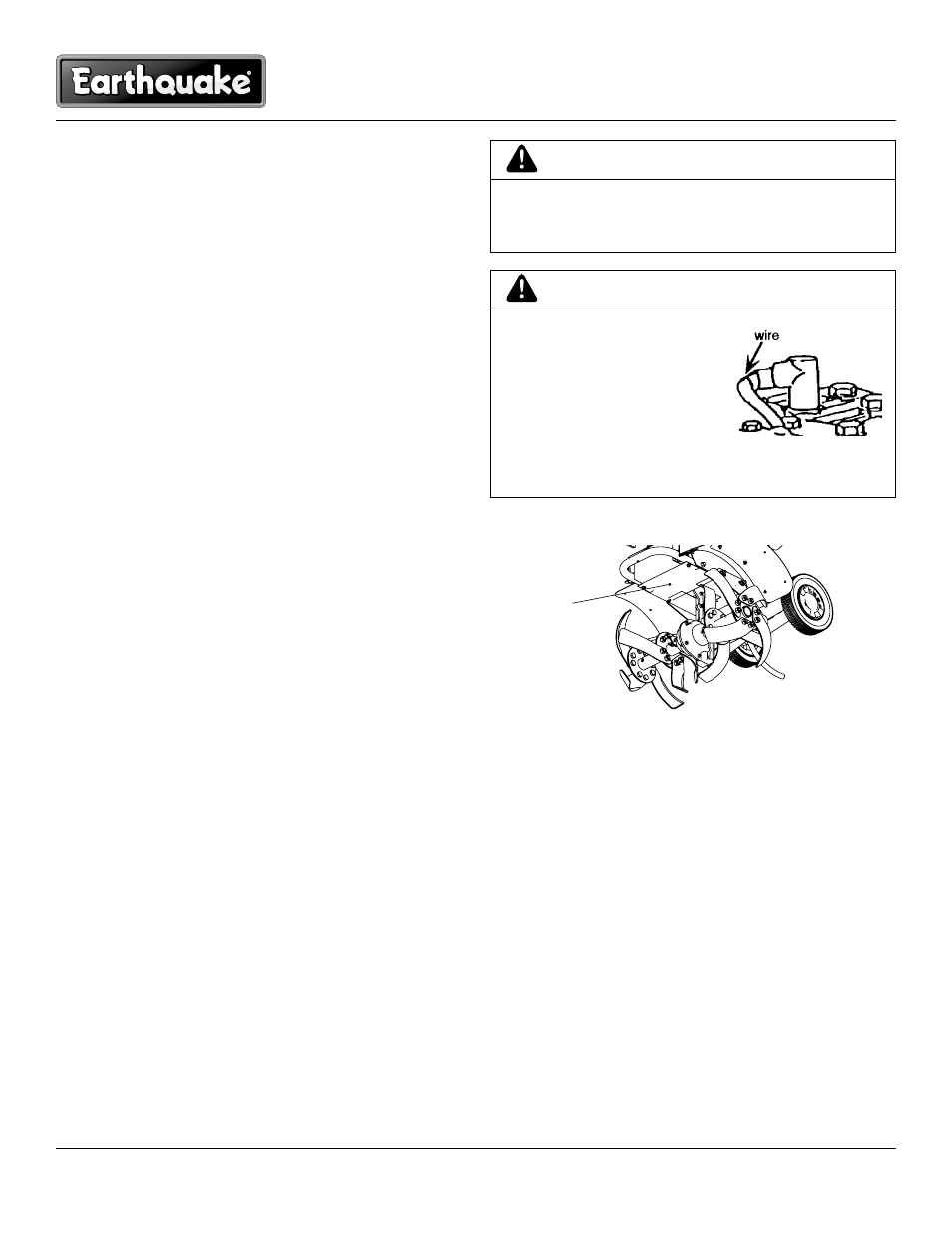

3. Remove front belt guard (331027A, Engine Seat Assembly Front).

SEE FIGURE 8.

• remove the belt from the engine pulley:

- gently pull the engine recoil rope to rotate the pulley.

- with the pulley turning, force the belt out of the groove.

- slide the belt free of the engine pulley.

- pull the belt down and out of the way.

- push the belt forward and out front of machine.

• install new belt:

- place belt in transmission pulley groove.

- gently pull the engine recoil rope to rotate the pulley while

forcing the belt into the groove.

4. Replace front belt guard (331027A, Engine Seat Assembly Front).

5. Attach spark plug wire.

BELT GUARD

Figure 8: Belt Tension Adjustment

(331027A, Engine

Seat Assembly,

Front)

WaRNING

ChECk FORWaRD BELT TENSION REGULaRLY.

TOO MUCh OR TOO LITTLE TENSION WILL CaUSE

PREMaTURE BELT FaILURE.

ENGINE MaINTENaNCE

Refer to the engine manual included in your parts packet for information on

engine maintenance. Your engine manual provides detailed information

and a maintenance schedule for performing the following tasks:

1. Check oil level before each use or after every 8 hours of operation.

2. Change oil after first 5-8 hours of operation. Change oil while engine

is warm. Refill with new oil of recommended grade.

4. Check spark plug yearly or every 100 hours of operation.

5. Service air cleaner.

6. Keep engine and parts clean.

7. Check engine and equipment often for loose nuts and bolts, keep

these items tightened.

ChECk OR FILL ENGINE CRaNkCaSE

1. Add oil according to engine manual. Do not overfill. Use a clean,

high quality detergent oil. Container must be marked A.P.I. Service

SF - SJ. Use no special additives with recommended oils. Do not

mix oil with gasoline. Oil level must be full. Check the oil level by

removing oil fill plug. Oil level should be up to the bottom of the fill

plug opening on most engines.

2. Always check oil level before starting engine. Refer to engine manual

for capacity and type of oil to use.

CLEaN TINE axLE ShaFT

1. Turn off engine. Engine must be cool.

2. Remove spark plug wire and secure from spark plug.

3. Remove all vegetation, string, wire, and other material that may

have accumulated on the axle between the inside set of tines and

the seal on the transmission housing.

4. Replace spark plug wire.

SERvICING ThE ROTOTILLER

The following information will help you make the necessary checks

and perform the procedures required to follow the normal care

recommendations made for your rototiller unit.

If you prefer, your local authorized dealer can make these checks and

perform the required procedures for you.

WaRNING

TO PREvENT aCCIDENTaL

STaRTING:

ENGINE MUST BE TURNED OFF

aND COOL, aND SPaRk PLUG

WIRE MUST BE REMOvED

aND SECURED FROM SPaRk

PLUG BEFORE ChECkING aND aDjUSTING ENGINE

OR EQUIPMENT.