Changing speed ranges – Delta 46-765X User Manual

Page 12

12

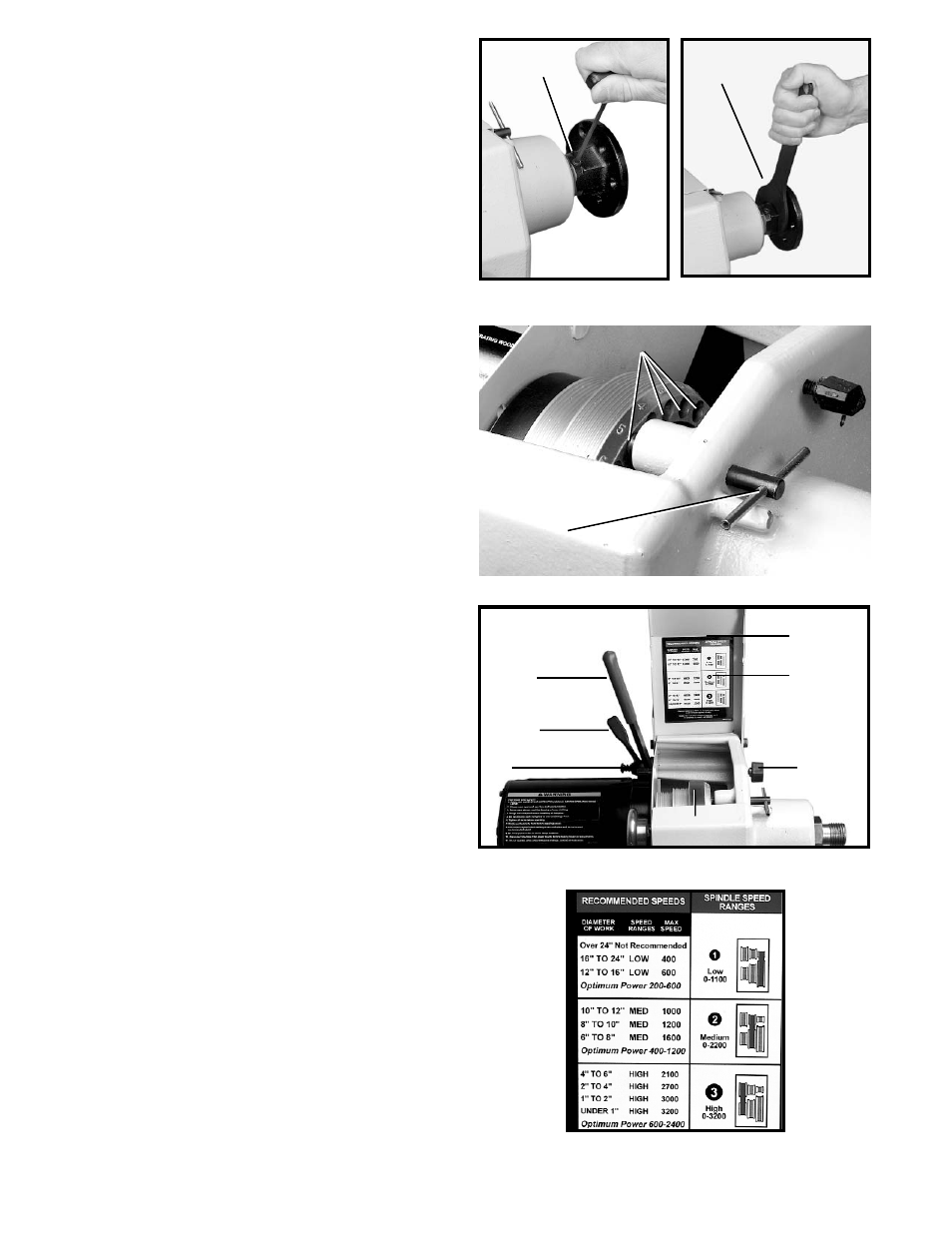

Fig. 24

A

B

Fig. 23

A

E

C

D

Fig. 25

F

6.

The REVERSE (REV) button is used FOR SANDING

PURPOSES ONLY. NOTE: When using the faceplate, be

certain that the faceplate locking screw (A) Fig. 23 is

tight. NOTE: To remove faceplate, loosen the set screw

(A) Fig. 23 two full turns. Use the supplied wrench (B)

Fig. 23B to loosen the faceplate, then remove the face

plate from the spindle.

IMPORTANT: For emergencies, use ONLY the safety

cover to stop the machine. Also, when leaving the

machine, be certain that the power to the machine is

off by lowering the safety cover. The control is still

energized as long as the power switch is on.

NOTE: To lock the spindle or to utilize the indexing fea-

ture, pull the spindle lock pin (A) Fig. 23C out and rotate

the pin clockwise. Re-engage it in the pulley holes (B)

Fig. 23C, some of which are shown. The spindle pulley

has 24 holes accurately spaced around the rim of the

pulley. This feature makes it possible to make evenly

spaced divisions on turnings which could be fluted,

grooved, or have holes drilled at these points.

CHANGING SPEED RANGES

Some turnings require different speeds. These machines

can utilize several different speed ranges. Use the fol-

lowing instructions to change the speed ranges for your

desired turnings.

1.

Loosen wing knobs (A) Fig. 24.

2.

Tilt cover (B) to open position, showing speed range

chart (C).

3.

Loosen lever (D) 1/4 turn.

4.

Pull lever (E) forward to remove tension from the

belt. NOTE: While lever (E) is in forward position, tighten

lever (D) to hold lever (E) in position while changing belt

positions.

5.

Move belt (F) to desired position (refer to chart) (C)

Fig. 24.

6.

Reverse the procedure to put everything back in

working order.

Fig. 25 shows the chart located inside the belt cover.

A

B

Fig. 23B

Fig. 23C

A

B