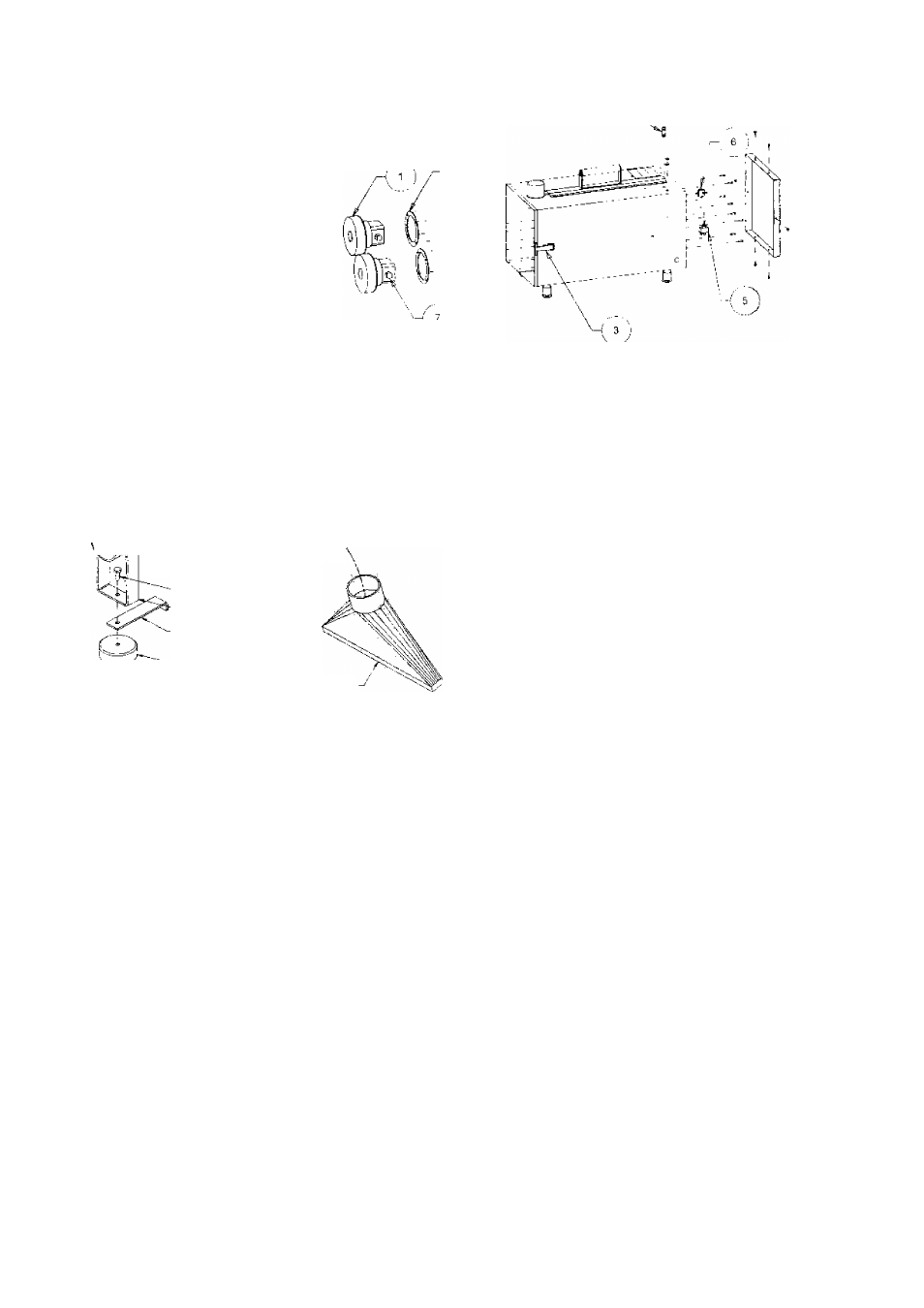

Figure 2, Operation, Maintenance & replacement parts – Ace 73-100 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

•U-

PRE-FILTER

IMSTALL PLEATS VERTICALLY

AS SHOWN

FLA- FIBER WAE.

(3 £A:

Figure 1

\

у SHUT-LOCK. A'*SHt4 IK

,

S

f

f .i

flFK TUBf ASSY

41 EA)

- HFK. HFA,":- ROlY i.'fl

?Q

к

2/4

i;i ÉAÌ

’■■•-— BRACKET HOSt SUPPORT

4T fA:

-sui>poRT

lfo

<1 CA)

MAGNCrrC BASI

(1 FAI

Ф'-.

STEtL

FuAf

WAS-tW

(1 EA;

HtX Ns."

(T EA|

RECTANGULAR S^OZZLF

О EA)

Figure 2

OPERATION

Your ACE Industrial Products machine is designed as a

source capture device, i.e., it is intended to eliminate

smoke and particulate at their point of origin. Keeping this

in mind, the machine should be operated in the following

manner:

Re-read the section on Safety Warnings & Cautions

before proceeding any further

1

Place the machine on a flat, level surface Pick a

location that will allow unrestricted flow of the exhaust

air to the atmosphere

2

For units with wheels or casters, lock the wheels or

block the wheels.

3

Place the collection nozzle as close to the work as

practical without interfering with the operator Secure

the nozzle if necessary.

4

Using the ON/OFF switch, turn the machine on.

Should the motor not start, or should the machine

make unusual noises, immediately turn the machine

off and seek trained maintenance personnel. Do not

continue to use the unit.

5

Upon completion of the specific manufacturing or

welding operation, turn the machine off. Continuous

running of the unit will reduce the life of the filter and

the motor brushes as well as increase utility cost.

6

When the "dogged" fitter light indicates that the filter

is clogged, turn the machine off and remove power

cord from its power source

See the section on installation and use the reverse

process to remove the dirty filters Re-install the new

filter and reconnect the machine to its power source

MAINTENANCE & REPLACEMENT PARTS

FILTERS:

As previously stated in the "Theory of Operation" section

of this manual, the "clogged" filter indicator light will light

whenever the differential pressure across the filter

indicates that the filter is clogged. When opening the unit,

there are no vacuum hoses to disconnect since the

pressure sensing is accomplished by measuring at the

inlet and inside the suction chamber. The differential

pressure trip point is preset and is not field adjustable.

If the “clogged" filter light should light, the pre-filter should

be changed first, since it is the least expensive of the two.

By changing the pre-filter on a regular basis, the main

filter will last up to 50% longer in most applications If

the light still lights after the pre-filter is changed, the main

filter is dogged and must be changed.