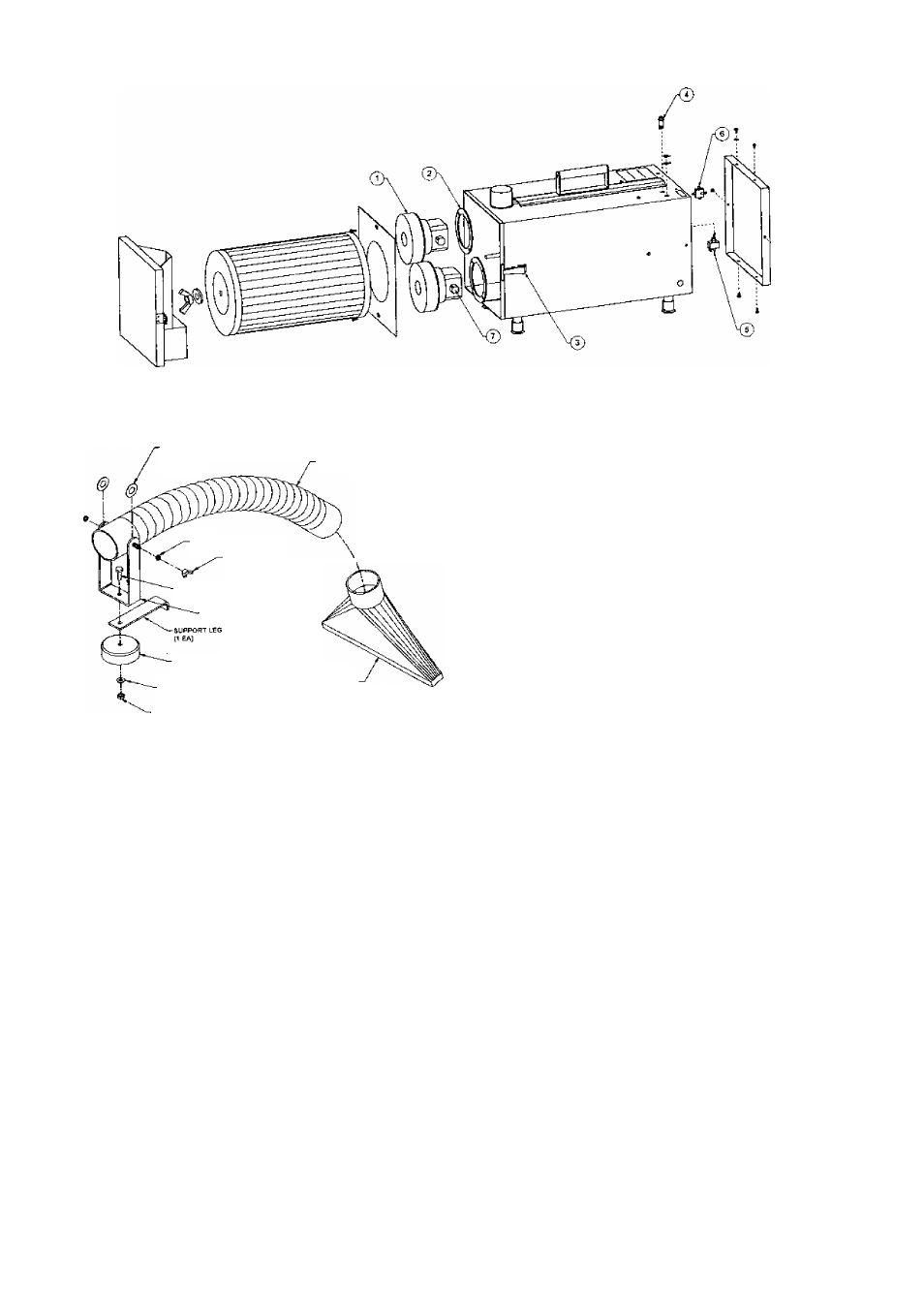

Figure 2, Operation, Maintenance & replacement parts – Associated Equipment 73-250 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Figure 1

FLAT FISER WASHER

P E A }

FLtJi TUBE ASSY

(1 EA)

SPLIT-LOCK WASHER

(£ ЕЛ)

WINO NUT 1M-20

PEA>

-• HEX HEAD BOLT T«-20 X

(t EA)

BRACKET HOSE SUPPORT MAGNETIC BASE STEEL FLAT WASHER 1 !*" HEX NUT irA-Ki KEPS RECTANGULAR NOZZLE (1 EA) Figure 2 OPERATION Your ACE Industrial Products machine is designed as a source capture device, i.e., it is intended to eliminate in mind, the machine should be operated in the following Re-read the section on Safety Warnings & Cautions 1. Place the machine on a flat, level surface. Pidt a location that will allow unrestricted flow of the exhaust 2. For units with wheels or casters, lock the wheels or block the wheels. 3. Place the collection nozzle as close to the work as practical without interfering with the operator. Secure 4. Using the ON/OFF switch, turn the machine on. Should the motor not start, or should the machine continue to use the unit. 5. Upon completion of the spedfic manufacturing or welding operation, turn the machine off. Continuous running of the unit will reduce the life of the filter and 6. When the "clogged" filter light indicates that the filter is dogged, turn the machine off and remove power cord from its power source. See the sedion on installation and use the reverse filter and reconned the machine to its power source. MAINTENANCE & REPLACEMENT PARTS FILTERS: . As previously slated in the "Theory of Operation section of this manual, the "dogged" filter indicator light will light whenever the differential pressure across the filter indicates that the filter is dogged. When opening the unit, there are no vacuum hoses to disconnect sin№ the pressure sensing is accomplished by measuring at the When the filter gets dirty, it needs to be replaced with a new one or the filter can be cleaned. To dean, take the filter out of the unit. Hold the filter 2 to 3 inches above a concrete floor. Gently drop the filter, rotate and repeat until vacuumed with a portable air vac (if needed, order 80- 201MD). To re-assemble, use reverse process to remove

(1 EA)

(1 £A)

(1 EA)

smoke and particulate at their point of origin. Keeping this

manner:

before proceeding any further.

air to the atmosphere.

the nozzle if necessary.

make unusual noises, immediately turn the machine

off and seek trained maintenance personnel. Do not

the motor brushes as well as increase utility cost.

process to remove the dirty filters. Re-install the new

inlet and inside the suction chamber. The differential

pressure trip point is preset and is not field adjustable.

most of the dirt falls out of the filter or the filter can be

filter and sweep up dirt that is on the floor.