Adjusting gas input, A. measuring gas flow at meter, Adjusting pressure regulator – Bryant Outdoor Heating Unit 379A User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Adjusting Gas Input

The gas input must be checked and adjusted, if

necessary, to agree with that shown on the unit rating

plate (150,000 Btuh). The burners are equipped with

fixed orifices. The burners on natural gas units use

No. 41 drill size orifices while the burners on the

propane units are equipped with No. 54 drill size

orifices.

The natural gas unit is equipped with an A639 gas

valve and a combination regulator/shutoff valve. The

propane gas unit uses an A639 gas valve but is not

equipped with a regulator. The regulator for propane

units is located at the supply tank.

CAUTION: The unit may be run for short periods

with the panels removed. Prolonged operation with

the panels removed should not be attempted.

One of the two following methods may be used to ad

just the gas input on a natural gas unit.

A. Measuring Gas Flow at Meter

All other gas appliances must be turned off when

measuring the gas flow at meter to adjust the gas in

put. Proceed as follows when using this method.

1. Determine the number of seconds required for the

gas meter test dial to complete one revolution.

2. Divide 3600 by the number of seconds in Step 1.

3. Multiply the result in Step 2 by the number of cubic

feet of gas flow per hour.

4. Multiply the result of Step 3 by the Btu heating

value of the gas (consult local utility for value). This

is the total measured Btu/hr input.

Compare this value with the one shown on the rating

plate.

Example: Suppose the size of the test dial is 2 cubic

feet; it takes 50 seconds for the dial to complete one

revolution; heating value of the gas is 1050 Btu per

cubic foot. Proceed as follows:

(a) 50 seconds to complete one revolution.

(b) 3600 divided by 50 equals 72.

(c) 72x2 = 144 cubic feet per hour of gas flow.

(d) 144x1050 = 151,200 Btuh input.

Only minor changes should have to be made at the

pressure regulator to bring it within the rated input of

the unit.

B. Using Water Manometer

When using a water manometer to measure the gas

manifold pressure, proceed as follows to adjust the

gas input.

1. Turn off gas to unit.

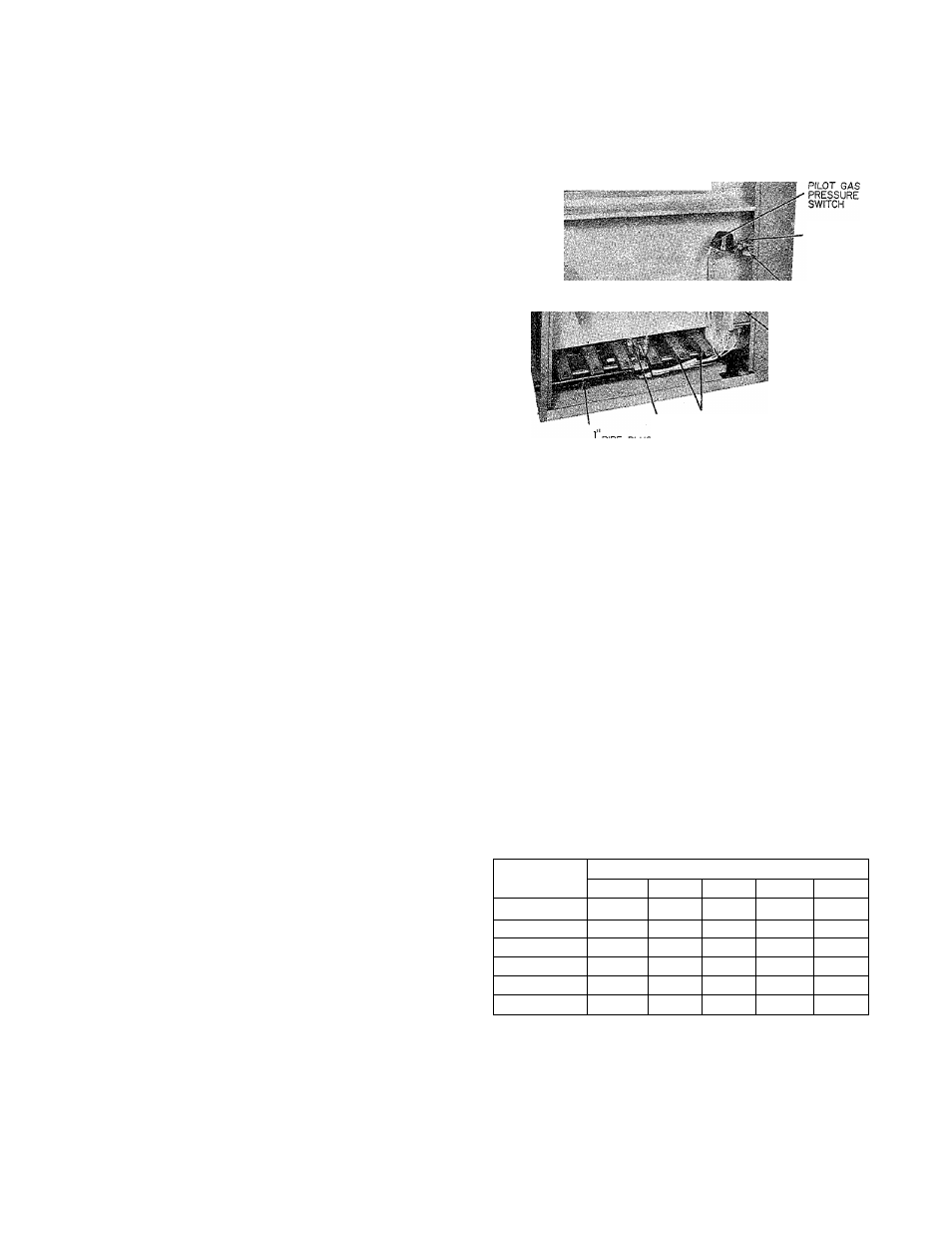

2. Remove the 1/8-inch pipe plug on the furnace

manifold and connect manometer here. See Figure 6.

3. Turn on gas to unit. With the burners fired, adjust

the pressure regulator to obtain the correct manifold

pressure as shown in Table IV. Check with local gas

utility for Btu value and specific gravity of gas in the

area.

39379D36

PILOT

GAS COCK

COMBINATION

REGULATOR-

SHUTOFF

VALVE

' GAS VALVE

PILOT BURNERS

A72154

Figure 6—Front View of Partially Disassembled

48W-379A

4. Remove manometer from manifold and replace the

1/8-inch pipe plug removed in Step 2 above.

Example: Heating value of gas is 1050 Btu and

specific gravity of gas is 0.63.

(a) From Table IV, the manifold pressure required

for 150,000 Btuh input is 2.8 inches water column.

(b) Set manifold pressure to 2.8 inches w.c. by ad

justing gas pressure regulator adjusting screw.

If required manifold pressure exceeds 3.3 inches w.c.

or is less than 2.7 inches w.c., the burner orifices

should be sized according to unit requirements. Con

sult your Bryant Distributor.

CAUTION: Do not redrill orificesunder any cir

cumstances.

TABLE IV — MANIFOLD PRESSURES

(Inches w.c.)

BTU

Specific Gravity

Value

0.59

0.61

0.63

0.65

0.67

900

3.6

3.7

3.8

3.9

950

3.2

3.3

3.4

3.5

3.6

1000

2.9

3.0

3.1

3.2

3.3

1025

2.8

2.9

3.0

3.1

3.2

1050

2.6

2.7

2.8

2.9

3.0

1100

2.4

2.5

2.6

2.7

2.8

Adjusting Pressure Regulator

If measured and rated input are not approximately

the same, the gas pressure regulator may be adjusted

as follows:

To increase input. Remove regulator sealing cap

and turn gas pressure regulator adjusting screw

clockwise.

To decrease input. Remove regulator sealing cap

6

—