Save these instructions, Switch fig – Black & Decker 4010 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

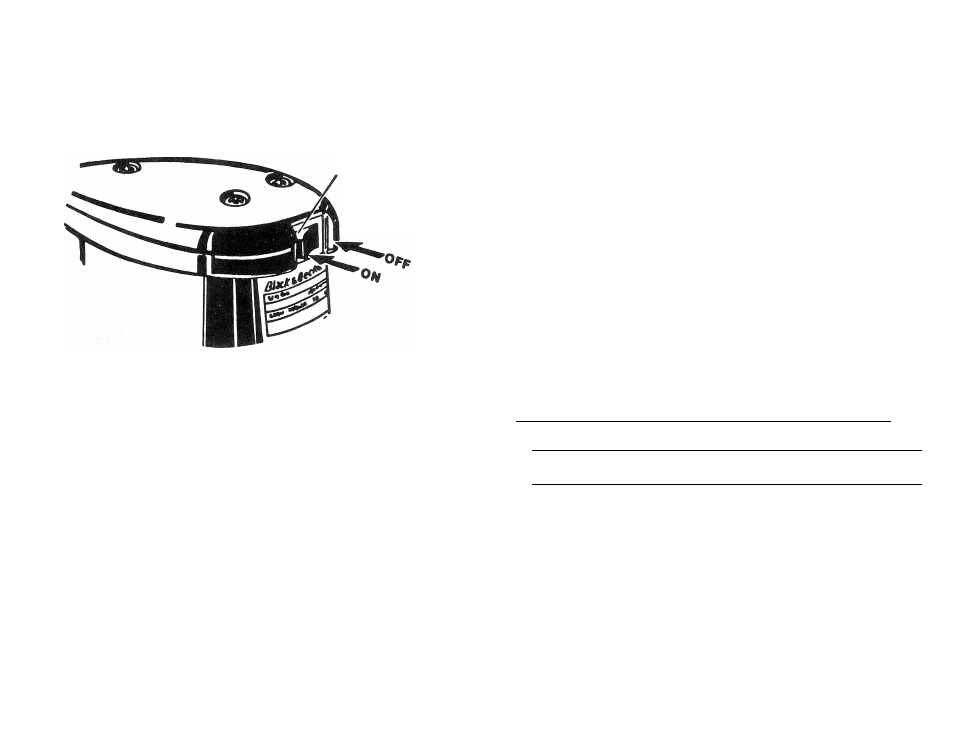

To operate unit, press right side of rocker switch. A white mark should appear to indicate

switch is in the

“on”

position. To stop unit, press left side of rocker switch. The white mark

should no longer be visible.

SWITCH

FIG. ?

HOLE PUNCH OPERATION (FIG, 8)

1. Remove the metal guide and the hole-puncher from the paper holder.

2. Place the paper^ grain upwards on the holder so that the paper is in contact with the

stop.

3. Place the metal guide above the paper so that it is correctly positioned in relation to the

holder.

4. With the aid of the holepuncher, make holes by pressing firmly through the guide and

the paper.

5. Take out the paper, checking that all the holes are clean and match the sender per

fectly.

6. If the holepuncher, after a considerable period of use, produces poor holes, then it is

essential to sharpen or replace it.

SPECIAL SAFETY INSTRUCTIONS FOR SANDERS

Always wear eye protection and a respirator when sanding.

DOUBLE INSULATION

Your Sander is DOUBLE-INSULATED to give you added safety. This means that it is con

structed throughout with TWO separate “layers” of electrical insulation or one DOUBLE

thickness of insulation between you and the tool’s electrical system.

Tools built with this insulation system are not intended to be grounded. As a result, your

Drill is equipped with a two-prong plug which permits you to use extension cords without

concern for maintaining a ground connection.

NOTE DOUBLE-INSULATION does not take the place of normal safety precautions when

operating this tool. The insulation system is for added protection against injury resulting

from a possible electrical insulation failure within the tool.

CAUTION: When servicing Double insulated Tools. USE ONLY IDENTICAL RE

PLACEMENT PARTS. Repair or replace damaged cords.

EXTENSION CORDS

Double insulated tools have 2 wire cords, and can be used with 2 wire or 3 wire extension

cords. Only round jacketed extension cords should be used, and we recommend that they

be listed by Underwriters Laboratories (U.L) (C.S.A. in Canada). If the extension will be

used outside, the cord must be suitable for outdoor use. Any cord marked as outdoor can

also be used for indoor work.

An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety, and to prevent loss of power and overheating. The smaller the gauge number of

the wire, the greater the capacity of the cable, that is 16 gauge has more capacity than 18

gauge. When using more than one extension to make up the total length, be sure each in

dividual extension contains at least the minimum wire size.

To determine the minimum wire size required, refer to the chart below.

............ CHART FOR MINIMUM WIRE SIZE

CORPS ^

NAME PLATE

TOTAL EXTENSION CORD LENGTH - FEET

RATING - AMPS 25

50

75

100

125

150

175

200

0-10.0

18

18

16

16

1 4

1 4

12

12

10.1-13.0

16

16

14

1 4

14

12

12

1 2

13.1-15.0

14

14

12

12

12

12

12

_

Before using an extension cord, inspect it for loose or exposed wires, damaged insulation,

and defective fittings. Make any needed repairs or replace the cord if necessary. Black &

Decker has extension cords available that are U.L (C.S.A in Canada) listed for outdoor

use,

MOTOR

Your Black & Decker tool is powered by a B & D built motor. Be sure your power supply

agrees with the nameplate marking.

Volts 50/60 Hz or “AC only” means your tool must be operated only with alternating cur

rent and never with direct current. Volts DC-60Hz or AC/DC means your tool may be op

erated with either alternating or direct current.

Voltage decrease of more than 10% will cause loss of power and overheating. All B&D

tools are factory tested. If this tool does not operate, check the power supply.

SAVE THESE INSTRUCTIONS