Extension cords, Double insulation, Electrical precautions – Black & Decker 3803-10 User Manual

Page 4: Saw chain maintenance, Chain sharpening - regular chain, Common filing errors

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

EXTENSION CORDS

Double insuitated toote have 2 wire cords, and can be used with 2 wire or 3 wire exten

sion cords. Only round jacketed extension cords should be used, and we recommend

that they be listed by Underwriters Laboratories (U.L.). If the extension will be used out

side, the cord must be suitable for outdoor use. Any cord marked as outdoor can also be

used for indoor work.

An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety, and to prevent loss of power and overheating. The smaller the gauge number of

the wire, the greater the capacity of the cable, that is 16 gauge has more capacity than 18

gauge. When using more than one extension to make up the total length, be sure each

individual extension contains at least the minimum wire size.

To determine the minimum wire size required, refer to the chart below.

CHART FOR MINIMUM WIRE SIZE (AWG) OF EXTENSION CORDS

NAMEPLATE

RATING-AMPS

25

TOTAL EXTENSION CORD LENGTH - FEET

50

75

100

125

150

175

200

0

-

10.0

10.1- 13.0

13.1- 15.0

18

16

14

18

16

14

16

14

12

16

14

12

14

14

12

14

12

12

12

12

12

12

12

Before using an extension cord, inspect it for loose or exposed wires, damaged

insulation, and defective fittings. Make any needed repairs or replace the cord if

neccessary. Black & Decker has extension cords available that are U.L. listed for

outdoor use.

DOUBLE INSULATION

Your Chain Saw is DOUBLE INSULATED.

This means that it is constructed throughout with TWO separate “layers” of electrical

insulation or one DOUBLE thickness of insulation between you and the tool’s electrical

system. Tools built with this insulation system are not intended to be grounded. As a

result the extension cord used with your saw can be plugged into any conventionaM20

Volt electrical outlet, without concern for maintaining a ground connection.

Note; DOUBLE INSULATION does not take the place of normal safety precautions

when operating this saw. The insulation system is for protection against injury resulting

from a possible electrical insulation failure within the saw.

Caution: When servicing Double Insulated Tools. USE ONLY IDENTICAL REPLACE

MENT PARTS. Replace or repair damaged cords.

Warning; When using an electric chain saw these basic safety precautions should

always be followed to reduce the risk of fire, electric shock and personal injury. READ

ALL INSTRUCTIONS.

ELECTRICAL PRECAUTIONS

SECURE CORDS as shown (FIG. 2) to prevent

disconnection.

AVOID ENTANGLEMENT. Keep cords clear

of operator, saw chain and branches at all

times.

GUARD AGAINST ELECTRIC SHOCK. Avoid

body contact with any grounded conductor

such as metal pipes and wire fences.

INSPECT EXTENSION CORDS periodically

and replace if damaged.

Inspect

Tool

Cords

periodically

and

if

damaged have repaired by Black

&

Decker

Authorized Service Center.

4

FIG. 2

SAW CHAIN MAINTENANCE

1. Keep the saw chain sharp at all times.

2. A dulled chain needs heavy pressure, and

overloads the motor and bar.

3. Cuttings (sawdust) should be in the form,

of chips.

4. Should they change to powder and the

motor labors, unplug the saw and sharpen

the chain.

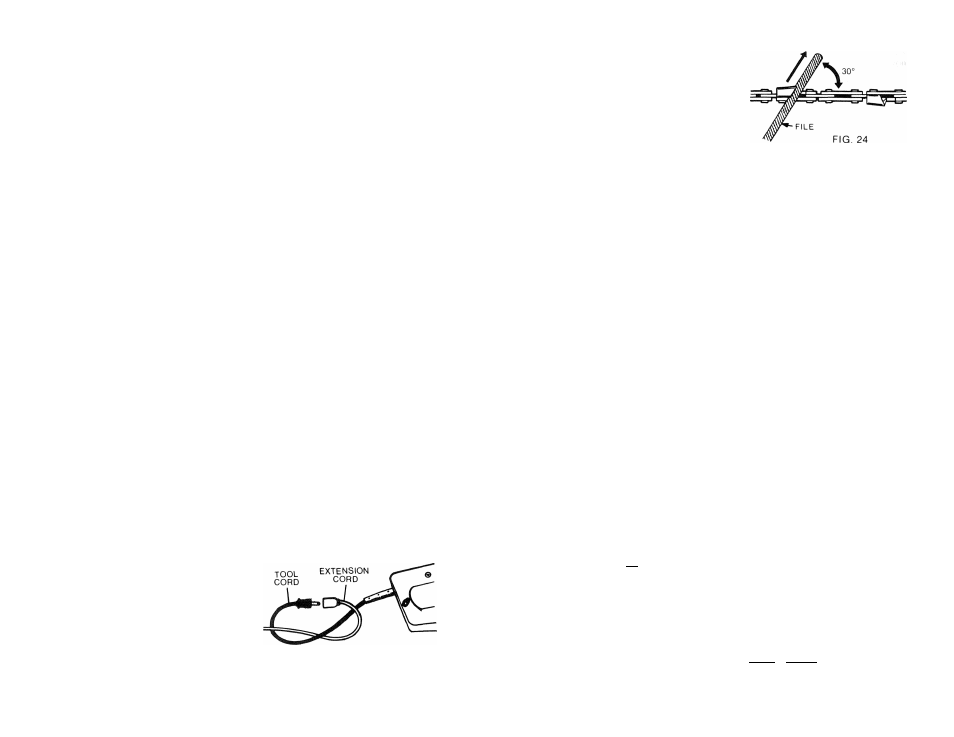

CHAIN SHARPENING - REGULAR CHAIN

Black & Decker saw chain is a precision manufactured cutting attachment and requires

regular inspection and care to maintain peak cutting efficiency. Touch up sharpening

may be required once or twice during a day’s wood cutting. In some areas where sand

or other abrasives have become embedded m the bark of trees, cutter teeth dull more

rapidly and more frequent sharpening may be required. As illustrated on FIG. 8, remove

the bar nut, flat washer, and bar plate. Using gloves, tilt bar so chain clears the sprocket

assembly and remove.

1. Cham can be sharpened on saw by replacing the bar in a bench vise while resting the

saw on the bench.

2. Use a 5/32 inch (3.9 mm) round file and guide marked for a 30'' top filing angle, P/N

38007.

3. Align the file guide at 30° angle, apply pressure against the face of the tooth, and push

the file toward the outside of the tooth. Release pressure on the cutting edge on the

return stroke.

4. Repeat sharpening stroke until tooth is sharp.

5. Sharpen ail teeth on one side of chain before sharpening teeth on the other side. Use

same number of strokes on each tooth to help keep all teeth the same length.

NOTE; Most chain problems are caused by incorrect filing, lack of lubrication, and/or

loose chain tension. Refer to troubleshooting chart for common filing errors. This chart

illustrates some of the most common signs to look for if the saw chain is not functioning

properly.

COMMON FILING ERRORS

All of these errors must be corrected by refiling.

Cutter Fault

Cause

Result

Hook

(a) File too small.

(b) Handle held too high.

Dulls quickly and will not cut

smoothly.

Backslope

(a) File too large.

SJ

(b) Handle held too low.

Cuts slowly and requires extra

pressure.

Depth Gauges

Not filed down,

too high

(

p

7

Cuts slowly, requires extra

pressure and leads to cutter

damage.

Depth Gauges<¿2=5^Too much filing.

too low.

Rough cutting, requires more

power (cuts 1

00

deep)

13