Engine maintenance – Bolens 248-645A User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

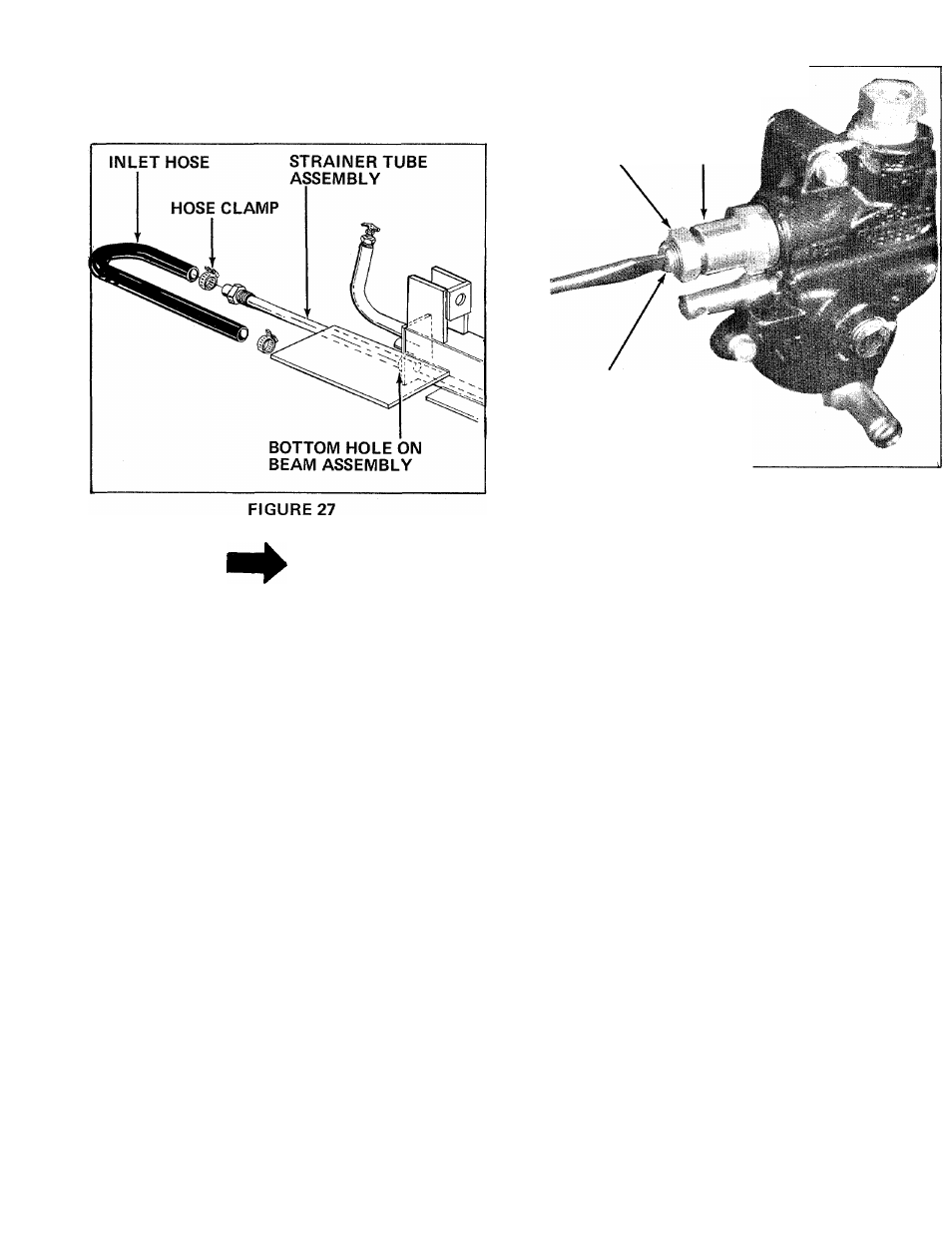

3. With an adjustable wrench remove the strainer

tube assembly. See figure 27.

NOTE

The strainer tube assembly is 53" long.

4. Clean and reassemble using a hydraulic pipe

sealant on the threads.

PRESSURE RELIEF VALVE SETTING

If the pressure relief valve is set too low it will open up

before enough pressure is built up to properly operate

the ram. See figure 28.

TO SET THE PRESSURE RELIEF VALVE

1. Remove the acorn nut on the Relief Valve.

2.

Loosen the locknut.

3. Have someone place a log crossways in the Splitter

and allow the Ram to push against it with the

engine running wide open.

4.

If the engine begins to lug down, the Relief Valve

setting is correct.

"“S. If adjustment is necessary, tighten the screw until

the engine begins to lug down.

6.

Shut off the engine, tighten the locknut and

replace the acorn nut.

PRESSURE RELIEF VALVE

LOCKNUT

SCREW

FIGURE 28

ENGINE MAINTENANCE

AIR FILTER

Under normal operating conditions, the air cleaner,

located on top of the carburetor, must be serviced

after every ten hours of use. Under extremely dusty

operating conditions, the air cleaner must be serviced

after every hour of operation.

1. Remove the wing nut and cover.

2.

Remove the second wing nut and metal disc

holding the foam and paper element.

3. Remove the two elements from the support base.

4.

To clean, tap the paper element (either top or

bottom) oh a flat surface.

13

5.

To clean foam element, wash in detergent and

solution by squeezing similar to a sponge. Wrap

foam in cloth and squeeze dry. Coat element with

two tablespoons of engine oil. Squeeze to

distribute and remove excess oil.