Black & Decker 97301 User Manual

Black & decker, Owner’s manual, Variable speed reversing drills

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

IMPORTANT INFORMATION --------------------------

Grounding

Your Drill has a grounding system to protect you from electric shock if

some damage should occur to the wiring of the tool. This system utilizes

the Drill's approved 3-conductor power cord and 3-prong grounding type

attachment plug, which should be used with the proper grounding type

receptacle, in accordance, with the National Electric Code, Canadian

Electrical Code, and Underwriters' Laboratories specifications.

GROUNDED OUTLET BOX

GROUNDING

PRONG IS

LONGEST OF

THE 3 PRONGS

fl

i • I 1

GROUNDED

OUTLET BOX-

^ADAPTER

green

GROUNDING

^^WIRE

GROUNDED OUTLET B0X.„

0

/

€)

GROUNDING

PRONG IS

LONGEST OF

THE 3 PRONGS

C

if

your unit requires less than 150 volts

it

has a plug that looks like Fig.

“A". It will fit directly into the proper type of 3-wire grounding receptacle.

The unit is then grounded automatically each time it is plugged in.

Shown in Fig. “B” is a special grounding adapter (not allowed in Canada

by the Canadian Electrical Code) which is available from your dealer and

will permit using a 2-wire receptacle. The green grounding wire extending

from the side of the adapter must be connected to a Permanent Ground.

If the unit requires from 150 to 250 volts, it has a plug like Fig. “C”.

No adapter is available and the plug must be used in the proper 3-wire

grounding receptacle.

We recommend that you NEVER disassemble the tool or try to do any

rewiring in the electrical system. Any such repairs should be performed

only by B&D Service Centers or other qualified service organizations.

Should you be determined to make a repair yourself, remember that the

green colored wire is the “grounding" wire. Never connect this green

wire to a “live" terminal. If you replace the plug on the power cord, be

sure to connect the green wire only to the grounding (longest) prong on

a 3-prong plug.

If you use an extension cord, be sure that it Is a 3-conductor, grounding

type cord. Grounding must be continuous from the tool plug to the

grounded receptacle.

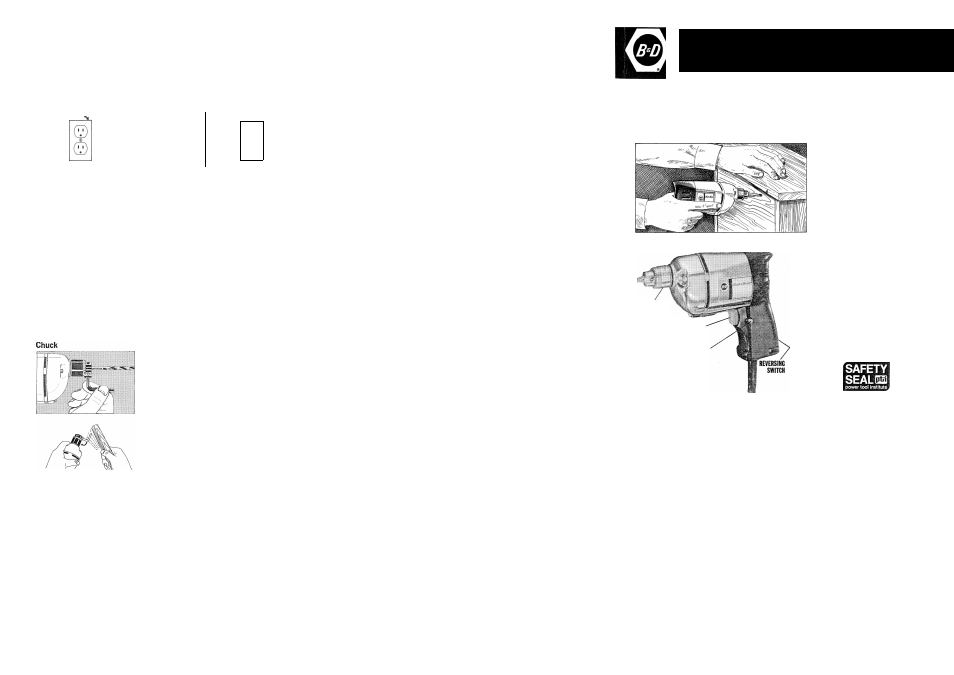

Turn collar to open chuck jaws. Place

bit in chuck so that end rests on

chuck bottom. Tighten chuck collar

by hand. Place chuck key in each of

the three holes, and tighten In clock

wise direction. It's important to

tighten chuck with all three holes. To

release bit, turn chuck key counter

clockwise in just one hole, then

loosen chuck by hand.

To remove the chuck from the Drill,

for using a threaded shank accessory

or for chuck replacement, first un

plug the tool. Open the chuck and

remove screw in bottom of chuck

(left hand thread). Insert the key in

the chuck and tap it sharply in the

direction the tool normally rotates --

see at left. This will loosen the chuck

shank threads and the chuck may be

unscrewed by hand.

Extension Cord

When using this drill at a considerable distance from power source,

a 3-conductor, grounding-type extension cord of adequate size must be

used for safety, and to prevent loss of power and over-heating. For a

120-volt tool, the minimum size of the wires in any extension cord up

to 75 feet long must be 18-gauge (American Wire Gauge). If the total

extension cord length is from 75 to 100 feet, 16-gauge wire is required

throughout the extension. 200-volt tools require a minimum wire size of

only 18-gauge in extension cord lengths up to 200 feet long. (NOTE:

16-gauge wire is heavier than 18-gauge wire and will carry current for

longer distances without a voltage drop.)

P.T.I. Safety Rule #12 applies to Extension Cords as well as the Tool

Power Cord. Before using cords, inspect them for loose or exposed wires

and damaged insulation. Make any needed repairs or replacement before

using your power tool.

Black & Decker.

OWNER’S MANUAL

MAINTENANCE.................................................... ..

If The Tool Does Not Run

First, check your electric outlet by plugging in another tool or lamp.

If either of these' doesn't work, check for blown fuses. If current is

present, check plugs and sockets for tight connections. If the tool still

won’t run, take or send it to a Black & Decker Service Center for checking

and repair. Do not attempt any major repair on your own.

Lubrication

Self lubricating bearings are used in the tool and periodic relubrication

is not required. However, it is recommended that, at least once a year,

you take or send the tool to a B&D Service Center for a thorough

cleaning, inspection and lubrication of the gear case.

Cleaning

UNPLUG DRILL. Use a rag dampened only with mild soap and hot water.

Many household cleaners contain chemicals which could seriously

damage the plastic handle. DO NOT let any water get inside the tool.

Guarantee

Black & Decker guarantees, for one year from date of purchase, to

correct by repair or parts replacement without charge any defect due to

faulty material or v^orkmanship. Simply return the complete unit,

transportation prepaid, to any Black k. Decker Service Center or

Authorized Service Station. Naturally, we assume no responsibility for

damage caused by misuse, careless handling or where repairs have

been made or attempted by others. No other guarantee, written or

verbal, is authorized by us.

Important!

To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by BLACK & DECKER Service Centers

or other qualified service organizations, always using Black & Decker

replacement parts.

mm

liiii

VARIABLE

SPEED.

TRIGGER SWITCH

SWITCH

LOCKING

BUTTON

Your new Black & Decker

Drill

is

an

outstanding

value,

combining

quality

construction, excellent per

formance and versatility.

Its special operating fea

tures are speed control and

a switch to reverse the di

rection of motor rotation.

Not only will it DRILL holes

in practically any material,

but with optional acces

sories it can SAND, POLISH,

BUFF, DRIVE SCREWS,

GRIND, DRIVE HOLE SAWS,

MIX PAINT, PUMP WATER

and REMOVE rust and old

paint.

For personal safety and for

proper operation of the

Drill, please take the time

to carefully read all of the

safety rules and instruc

tions in this booklet. Don't

forget to send in the guar

antee registration card.

THANK YOU for buying

BLACK & DECKER!

VARIABLE SPEED REVERSING DRILLS

» # # I

I ® ® (

' ® ® ® ® ® (

SM'Tools-Electric

—Yellow Pages—

for Service I Sales

THE BLACK & DECKER MFC. CO.

Towson, Md. 21204, U.S.A.

1/4" DRILL

Capacity:

dia.

holes in steel;

Y2" dia. in hardwood. 120 Volts

A.C. 2.0 Amps. 1/6 H.P. 2250

R.P.M.

3/8" DRILL

Capacity: %" dia. holes in steel;

%" dia. in hardwood. 120 Volts

A.C. 2.4 Amps. 1/6 H.P. 1000

R.P.M.

Form

No. 97301

(C3-AL) Printed in U.S.A.