Final adjustment, Parts and service – Briggs & Stratton 81900 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION fV

SECTION IV — ADJUSTMENTS (Cont'd)

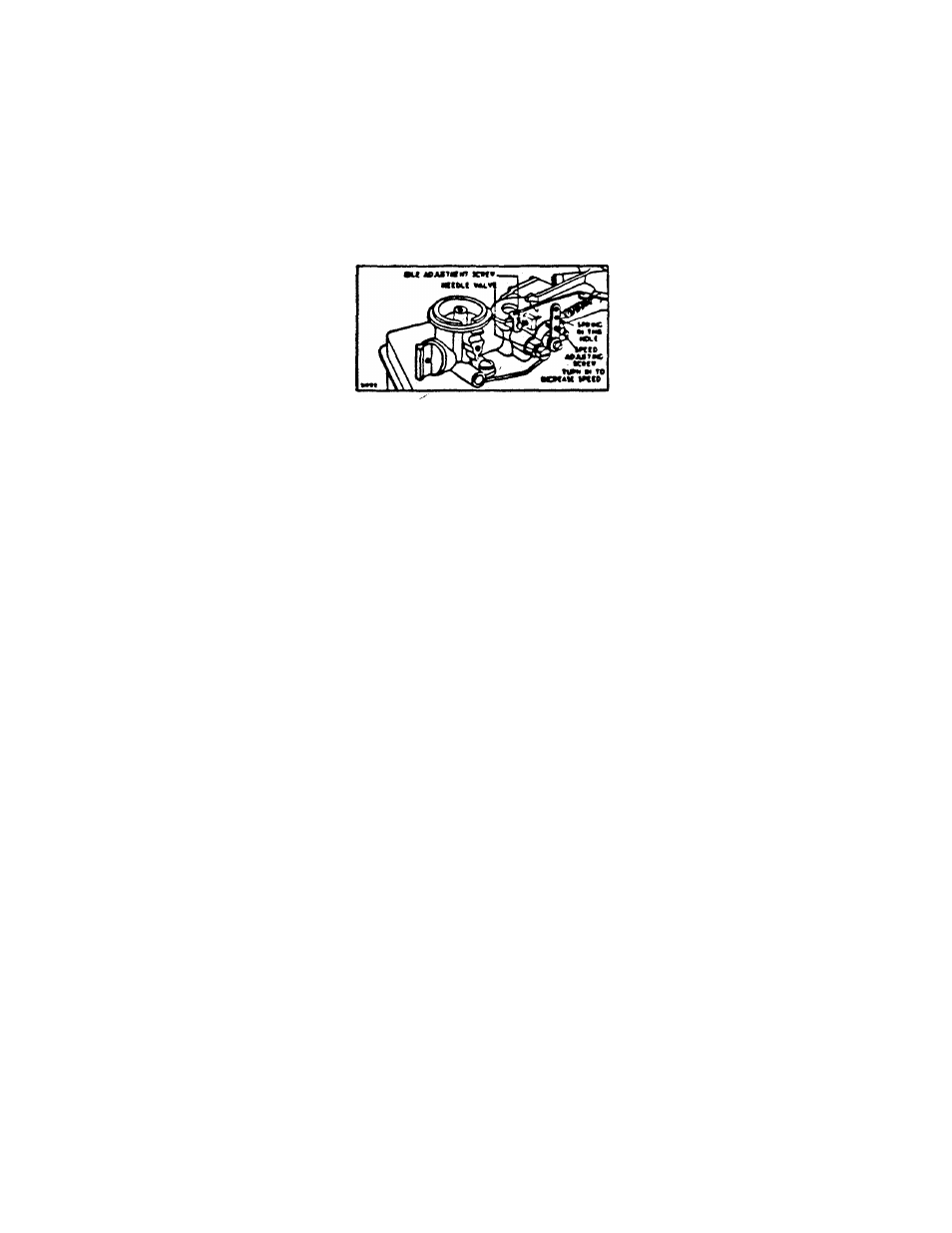

InKUl Uju(tm«nt:

Dose

ne«dle

valvt

(turn

clockwite]

then open 1V& turns (turn counter

clockwise). This initial adjustment will

permit the ermine to be started and

warmed up before makinf final ad

justment

Final Adjustment

With engine running at normal opera

ting speed (approximately 3000 R.P.M.

without load) close the needle valve

(turn clockwise) until engine starts to

lose speed (lean mixture). Then slowly

CARBURETOR AOJUSTMCNTS

Open needle valve (turn counter-clock

wise), pest the point of smoothest op

eration, until engine just begins to run

unevenly. This mixture should be rich

enough for best performance ur>der

loed.

Hold throttle in idling position. Turn

idle fpeed adjusting screw until fast

idle is obtained (1750 R.PJd.).

Test the engine under full load. If eiv

gine tends to stall or die out, it usually

if>dicates that the mixture is slightly

lean and it irtay be necessary to open

the needle valve slightly to provide a

richer mixture. This richer mixture may

cause a slight unevenness in idling-

SECTION V

PARTS AND SERVICE

eCHERAt. INFORMATION

These engines art single-cylinder, L-head, air-ceoled type.

MODEL SERIES ^

80900 to 80996

end 81900 to 81996

Bore............................................................... 2 3/8"

Stroke............................................................ 1 3/4"

Displacement............................................ 7.7 cu. in.

Horsepower......................3.0 HP mox. § 3600 RPM

The horsepower ratings listed above are established by standard I.C.E.I. procedures.

For practical operation, the horsepower loading should not exceed 85% of these

ratings. Engine power will decrease 3V^% for each i,000 ft. above saa level and 1%

for each 10 degrees above 60 degrees F.

TUNE-UP SPECIFICATIONS

Spork Plug Type

AC*(»C-46;

AL>A7R; Chomp. J8.

Spork Plug Gap...............................025"

Ignition Point (àop.........................020"

Intoke Volve Cleerence . .005"-.(X)7"

Exhoust Volve Cleoronce J)09">.011"

CAUTION: Blast Cleaning of spark plugs

in machines that use abrasive grit is

not recorrunended. Spark plugs should

be cleaned by scraping

or

wire brush

ing and washirg with a commercial sol

vent

or

psoline.

Major engine repairs should not be at

tempted unless you have the proper

tools and a thorough knowledge of in

ternal combustion angines.