Drilling in masonry, Drill accessories, Maximum recommended capacities – Black & Decker 5065 User Manual

Page 3: Carbon removing brushes, 3" wire cup brush, Hammer/drill selector, Chuck key holder, Chuck, Holder

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Drilling in Masonry

Refer to the same list of instructions

under ‘DRILLING’', but use percussion

Masonry drill bits only. Drill in masonry

only. Keep even force on the drill but not

so much that you crack the brittle

materials. A smooth, even flow of dust

indicates the proper drilling rate.

Drill Accessories

The accessories listed in this manua,

are available at extra cost from your local

dealer or Black & Decker Service Center.

A complete listing o1 service centers is

included on tne owner’s registration card

packed witri your tool.

If you need assistance in locating

any accessory, please coniac:: Black &

Decker, (U.S.' me.. User Services

Department, 626 Hanover Pike, P.O. Box

618, Hampstead, MD 21074-0618.

Every Black S Decker loo' is oi the

highest quality. !i you wish to contact us

regarding this product, please call toll free

between 8:00 a.m. and 5:00 p.m. EST

Monday through Friday. 1 -800-762-6672

Recommended accessories io" you:

Drill are shown in this manual (CAUTION:

The use of any other accessory might be

hazardous.) For safety in use, the

following accessories should be useo onlv

in si.zes UD to the maximums snowri in

table below.

Maximum

Recommended

Capacities

DRILL CAPACITY

R.P.M.

0-900/0-2200

BITS, METAL DRILLING

1/2"

WOOD, FLAT BORING

1"

BITS, MASONRY DRILLING 3/4"

HOLE SAWS

1-1/8"

WIRE WHEEL BRUSHES-

WIRE CUP BRUSHES —

BUFFING WHEELS

— 4" Dia. Max.

3" Dia. Max.

— 3" Dia. Max.

RUBBER BACKING-

PADS

■ 4-5/8" Dia. Max.

ACCESSORY MUST BE RATED FOR

USE AT SPEED EQUAL TO OR

HIGHER THAN N.AMEPLATE R.P.M.

OF TOOL WITH WHICH IT IS BEING

USED.

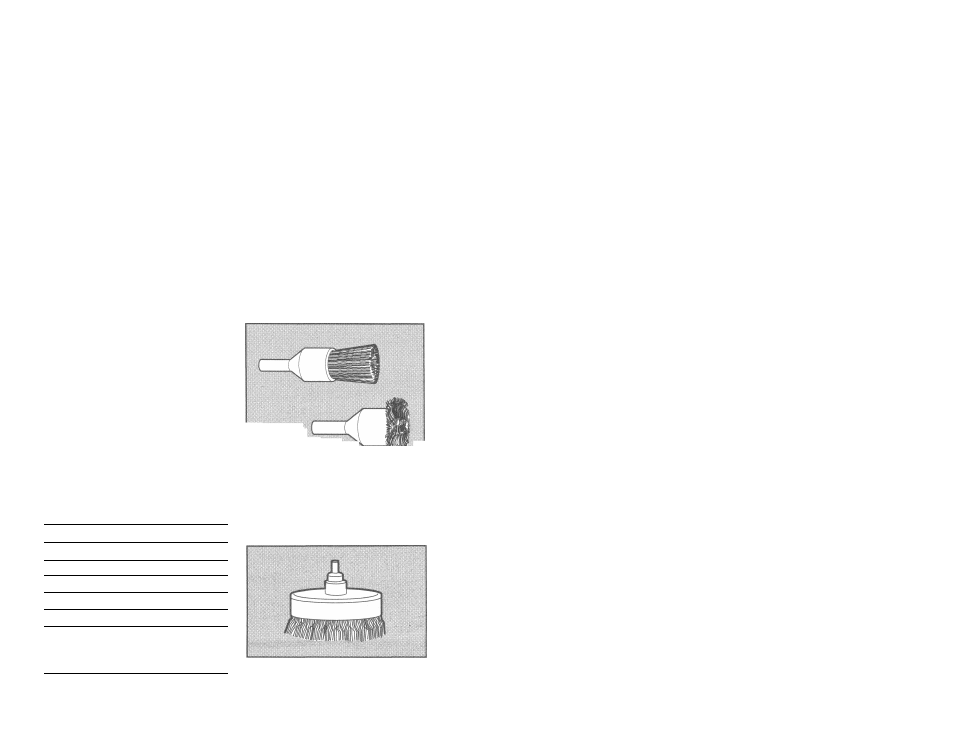

Carbon Removing

Brushes

Made of tempered-steel wire; used

with drills to remove rust and scale from

metals. Leaves a burnished surface.

A. Heavy-duty solid wire-filled brush.

B. Side-flare brusii for close corner

work

C. Hollow-core flare-bottoiTi brush.

Small cleaning brush. (No: shown.'

3" Wire Cup Brush

Use in cleaning and removing rust,

scaie, old pain.. (Straight chuck snank,.

Maximum safe RPM—5,000.

mil

Your Hammer Drill is equipped with

dual range speed control for greater

versatility. To change from one range to

the other, turn the too! off and then rotate

the range control dial. shov\/n in Figure 3,

to the desired position. Turn Hie dial so

that the symbol 1 is toward the chuck for

low speed (0-90C RPM). If you want high

speed (0-2200 RPM) lurn the dial so thal

the symbol li is toward the chuck

NO"!"E; It may sometimes be necessary

to manually turn the spindle slightly

when shitting from one ranae to anot'nei.

DO NOT SHIFT WHEN THE TOOL IS

RUNNING OR COASTING.

The tool mus- be fully engaged into

range I or range II. Make sure that the

selector is noi somewhere between the

two; damage to the unit may result.

IHilil

i toward the chuck. For hammering, align

\ the hammer symbol with the chuck, as

stiown in the figure.

NOTE: The selector must be in either

drill or hammer mode at all times. There

are no operable positions between the

two.

Hammer/Drill Selector

To switch the tool from the drilling mode j

to the hammering moae io- vice-versa) ;

rotate the dial, snown m Figure 4, so that |

tne desirec position is accomolisheo. For |

straigh: driliing. align the drÜ! bit symbol

Ciici lii ief

UNPLUG DRILL. Open chuck jaws

and inserì shank of bi; aboui inio

chuck. Tighten chuck collar by hand.

Place chuck key in each of the three

•loles,

and iigkaen ir clockwise direction.

It’s important to tighten chuck with all

three holes to prevent slippage of drill bit

in chuck. To release bit, turn chuck key

coLinierciocKwise in

jusi one hoie, ther

loosen chuck by hand.

Chuck

Key

Holder

1. Push double-hole end of holder

through slot in other end of Holder.

(Figure 5).

2. Slip loop over electric plug and draw

loop tight around cord (Figure 6).

3. Push ends of Chuck Key Handle

through two holes in end of Holder

(Figure 7).