Additional safety information for drills, Switches, Brushes – Black & Decker 5065 User Manual

Page 2: Stop, Wire wheel brushes, Buffing wheels, Rubber backing pad, Wheel arbors, Sanding discs

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Additional Safety

Information For Drills

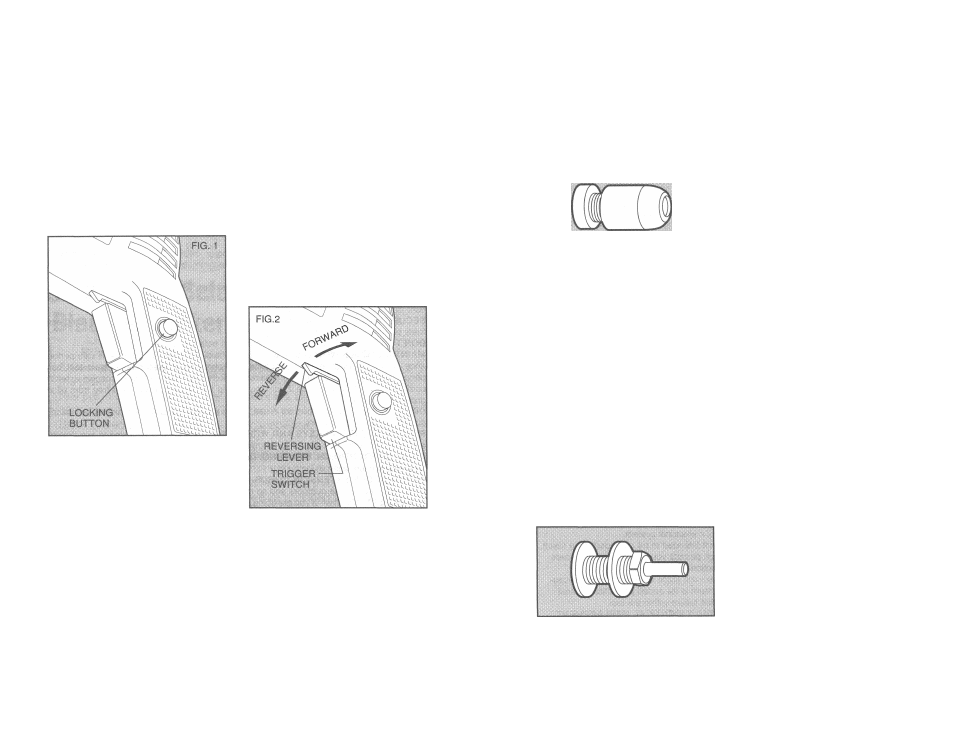

1. The switch lock feature must be

used

'With

caution due to the high

torque output of the tool (See Figure

1

). , ,

2

.

Do not attempt to change from

hammer to drill mode while tool is

running.

Switches

To start unit, depress trigger switch;

to stop unit, release trigger. To lock

trigger in “ON" position for continuous

operation, depress trigger and push in

locking button Figure 1, then gently

release trigger. To release locking

mechanism, depress trigger fully, then

release it. Before using the tool {each

time) be sure that the lock button release

mechanism is v\/orking freely.

Be sure to release the switch

locking button before disconnecting the

?c cause the tool to start immediately

the rex: hr*e *: T c'ugced ;c. Damage or

injury could result

WARNING: The switch lock feature

must be used with caution due to the

high torque output of this unit.

The Variable Speed Trigger Switch

permits speed control. The farther the

trigger is depressed, the higher the

speed of the unit.

For maximum tool life, use lower

speed only for starting the hole. Continu

ous use at lower speed is not recom

mended.

The Reversing Lever is used for

removing jammed drill bits, or backing

out screws. It is located above the trigger

switch, as shown in Figure 2. To operate

the tool, in reverse, push the reversing

lever to the right, shown in Figure 2.

When reversing operations are con

cluded, return the lever to the forward

Dosition, as shown in the figure.

Brushes

Your tool is equipped with Black &

Decker brush checkpoint system. When

the brushes become worn out the tool

will automatically stop and prevent

damage to the motor. Return the tool to a

Black & Decker Service Center for brush

replacement. ^

a ^ {

Stop

Capacity 'I/4" to 1/2" Governs

drilling depth.

Wire Wheel Brushes

Use in cleaning and «'amoving rust,

scale, old paint. 4" Fine Brush, crimped:

Viaximum sate PPM—4,500 4" Coarse

Brush, crimped; Maximum safe RPM—

^O500.

#1

Buffing Wheels

Use with 1/4" to 1/2" Drills and

Wheel Arbors. 3" x 3/8" x 1/2" Cotton

Buff.

è

Rubber Backing Pad

Fit 1/4" to 1/2" Drills. 4-5/8" Rubber

Backing Pad with plain shanK. Used «or

sanding operations.

L

J

»

Wheel Arbors

Fit 1/4" to 1/2" Drills. Carry wire

wheel brushes and buffing wheels.

Sanding Discs

Use with Rubber Sacking Pad.