Safe operation practices (continued), Blade brakeiclutch maintenance, Note – MTD 114-074-000 User Manual

Page 4: Lower handle, Assembly, Contents of hardware pack: (see figure 1)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SAFE OPERATION PRACTICES (Continued)

BLADE BRAKEICLUTCH MAINTENANCE

NOTE: Any required repair work on the biade

brake/clutch should be performed by an author- 3.

ized service dealer. If you cannot locate an author

ized service dealer, contact the manufact jrer as

set forth on your copy of the Owner’s Registration

Card.

1. The blade brake/clutch hand control is a safe

ty device. Never attempt to bypass its opera

tion. Doing so makes the safety device in

operative and may result in personal injury

through contact with the rotating blade. This 4.

hand control must operate freely in both direc

tions.

2. Striking a solid object can cause daniage to

the blade brake/clutch or to the engine crank

shaft. Extensive vibration of the mowei during

operation is an indication of damage and the

unit

should

be

promptly

inspected

and

repaired.

A leak in the lower engine crankshaft oil seal

could expose the blade brake/clutch friction

pads to excess oil resulting in blade or brake

slippage, which could increase the stopping

time of the blade. Oil collection on the floor

beneath the mower during storage may be an

indication of an oil seal leak. The unit should

be checked by an authorized service dealer.

Periodically inspect the inner control cable in

the area where it attaches to the hand control.

If the cable becomes frayed, it could cause

the blade brake/clutch to operate improperly.

Also, be careful to avoid pinching the blade

brake/clutch control cable when storing the

handle.

NOTE

This unit is'shipped WITHOUT GAS

OLINE or OIL. After assembly, see

separate engine manual for proper

fuel and engine oil recommenda

tions.

ww

-B

,_F

FIGURE 1.

Lower Handle-

4

у

Hairpin i

Cotter (A)

in Inner

Hole

Handle

Bracket

ASSEMBLY

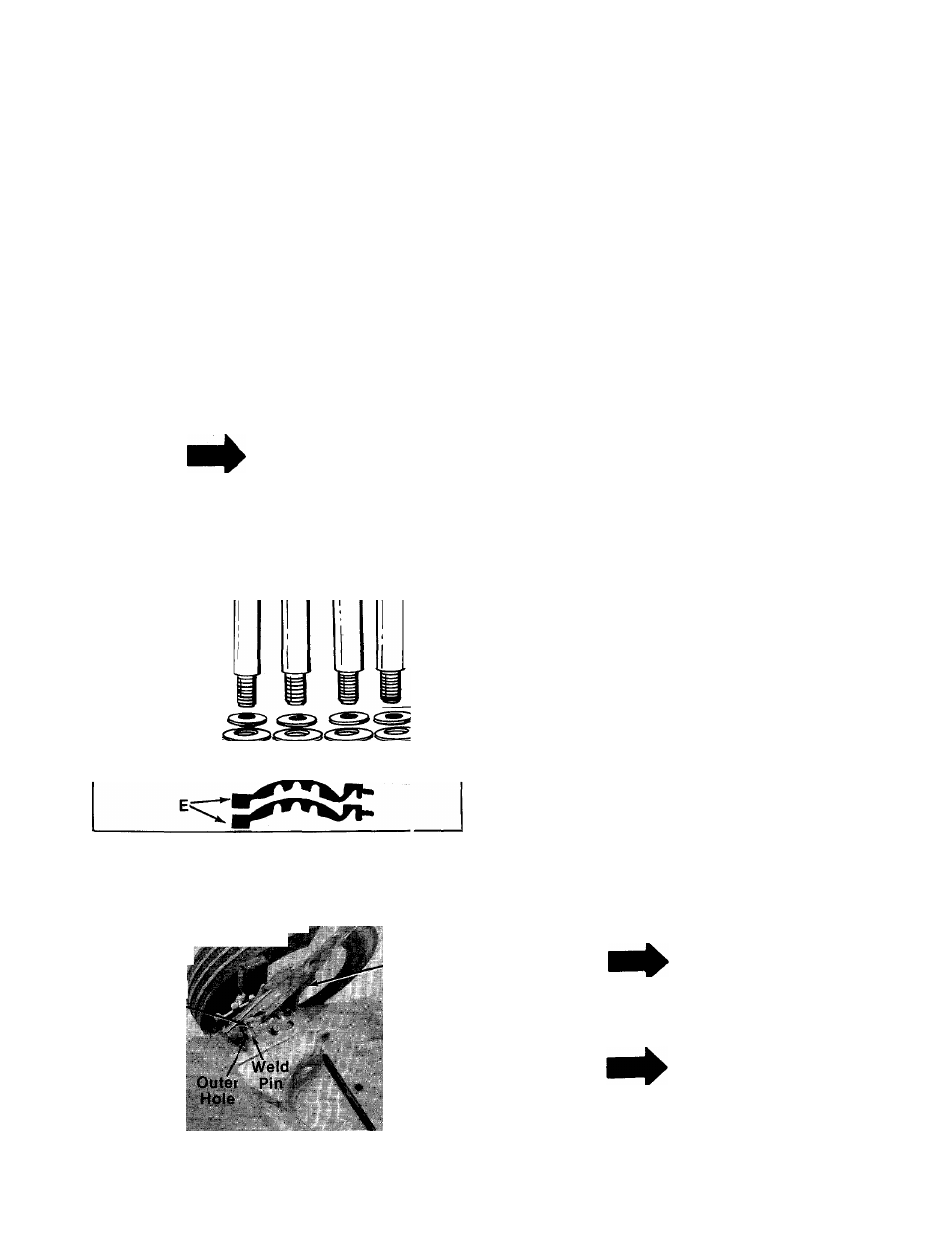

Contents of hardware pack: (See figure 1)

A (2) Hairpin Cotters

В (2) Curved Carriage Bolts 1.38" Long

C (2) Lock Washers 5/16" I.D.

D (2) Hex Nuts 5/16-18 Thread

E (2) Cable Ties

F (4) Shoulder Bolts*

— G (4) Belleville Washers 3/8" I.D. x 7/8" O.D.*

H (4) Belleville Washers 3/8" I.D. x 1-1/8" O.D.*

I (4) Hex Nuts 3/8-16 Thread*

*Units with wheeis not assembied.

1. Remove the iawn mower, ioose parts, hard

ware pack and iiterature from the carton.

Make certain all parts and literature have been

removed before the carton is discarded.

2. Extend the throttle control cable (attached to

the upper handle) and the blade brake/clutch

cable (attached to the blade brake/clutch

beneath the deck) and place on the floor. Be

careful not to bend or kink control cables.

3. Place lower handle in position over weld pins

in handle mount brackets on deck. Make cer

tain the instruction label on the lower handle

can be read from the operating position.

Secure by placing two hairpin cotters (A) in in-

------ ner hole on weld pins. See figure 2.

FIGURE 2.

NOTE

It may be "necessary to bend the

ends of the lower handle outward

slightly to obtain a snug fit against

the bracket.

NOTE

There are two (2) holes in the handle

mount brackets. Place hairpin cot

ter in the inner hole for operation.

The outer hole is for storage.