Lubrication, Carburetor adjustments, Maintenance – MTD 110-428R000 User Manual

Page 13: Trouble shooting, Cuning blade, Lubrication maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2

.

3.

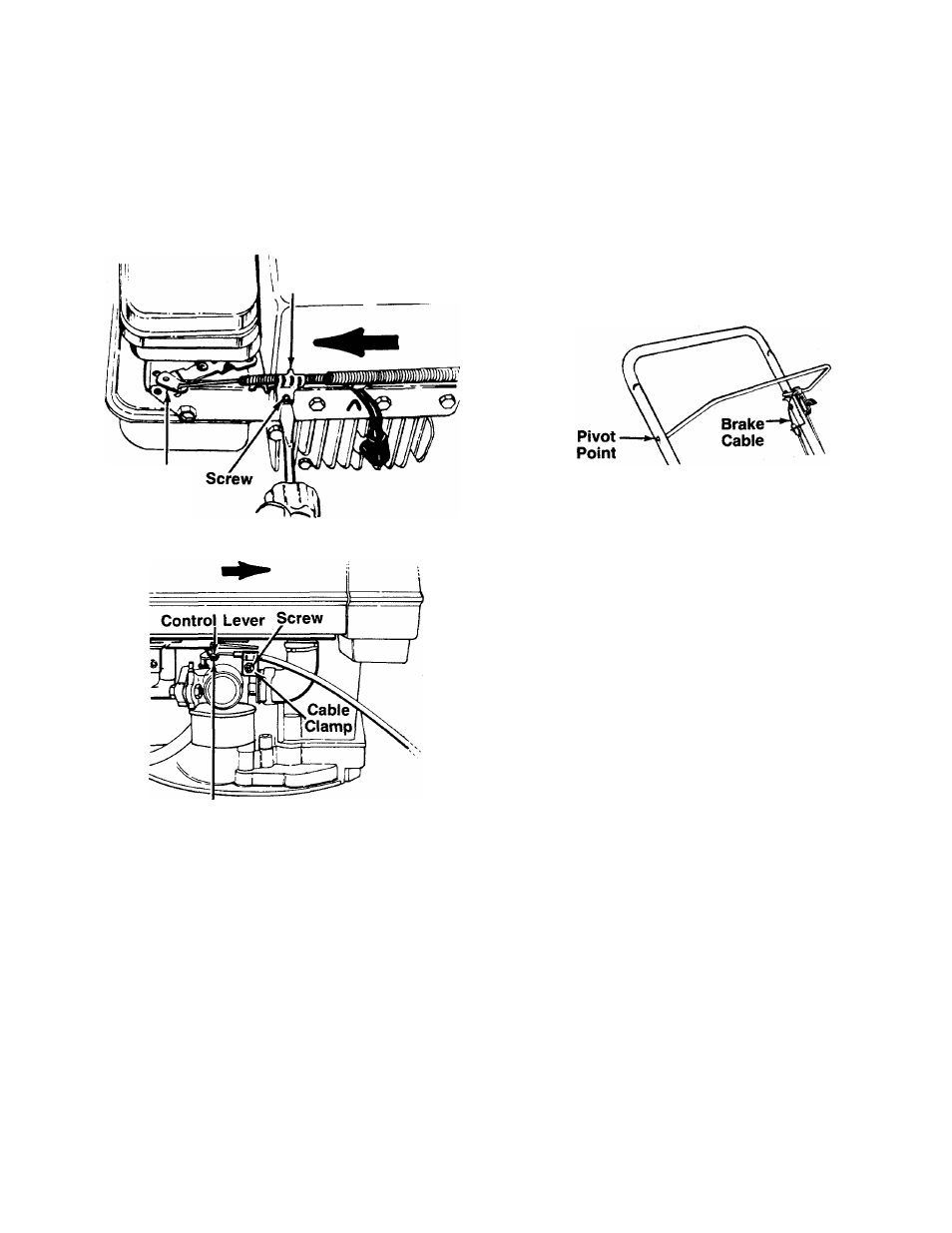

Place the throttle control lever on the handle all the

way forward to START position.

Place the control lever on the engine in the full

open position by pushing it as far toward the out

side (Briggs and Stratton engine) or rear

(Tecumseh engine) of the engine as it will go.

Tighten the screw on the cable clamp to secure

the cable in this position.

Cable

1 Clamp

LUBRICATION

Control

Lever

On Engine

FIGURE 21A.—Models 410R, 412R, 420R, 422R

“Z” End

of Cable

FIGURE 21B.—Models 415R and 425R Shown

CARBURETOR ADJUSTMENTS

A

WARNING: If any adjustments are made to

the engine while the engine is running (e.g.

carburetor), keep clear of all moving parts.

Be careful of heated surfaces and muffler.

Minor carburetor adjustments may be required to

compensate for differences in fuel, temperature,

altitude and load.

To adjust carburetor, refer to the

separate engine manual packed with your mower.

NOTE: A dirty air cieaner wiil cause an engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Refer to the

separate engine manual.

A

WARNING: Always stop engine and

disconnect spark plug wire before clean

ing, lubricating or doing any kind of work

on lawn mower.

Blade Control—

Lubricate the pivot points on the blade

control handle and the brake cable at least once a

season with light oil. See figure 22. The blade control

must operate freely in both direction^

FIGURE 22.

Discharge Chute Deflector—

The torsion spring and

pivot point should be lubricated periodically with light

oil to prevent any rust or binding. Deflector must work

freely.

Wheels

—Mower may be provided with ball bearing

wheels. Lubricate at least once a season with light oil.

Also, if the wheels are removed for any reason,

lubricate the surface of the axle bolt and the inner sur

face of the wheel with light oil. A 4 oz. plastic bottle

of light oil lubricant is available. Order part number

737-0170. Engine oil may also be used.

Engine—

Follow engine manual for lubrication in

structions.

Throttle—

Periodically lubricate throttle control lever

and throttle wire assembly with a few drops of light oil

for ease of operation.

MAINTENANCE

A

WARNING: Be sure to disconnect and

ground the spark plug wire before perform

ing any repairs or maintenance.

NOTE: When tipping the unit, empty the fuel tank and

keep engine spark plug side up.

TROUBLE SHOOTING

Refer to page 15 of this manual for trouble shooting

information.

CUniNG BLADE

When removing the cutting blade for sharpening or

replacement, protect hands by using heavy gloves or

a rag to grasp the cutting blade. Remove the bolt and

13