Assembly, Operation – MTD 111-500 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

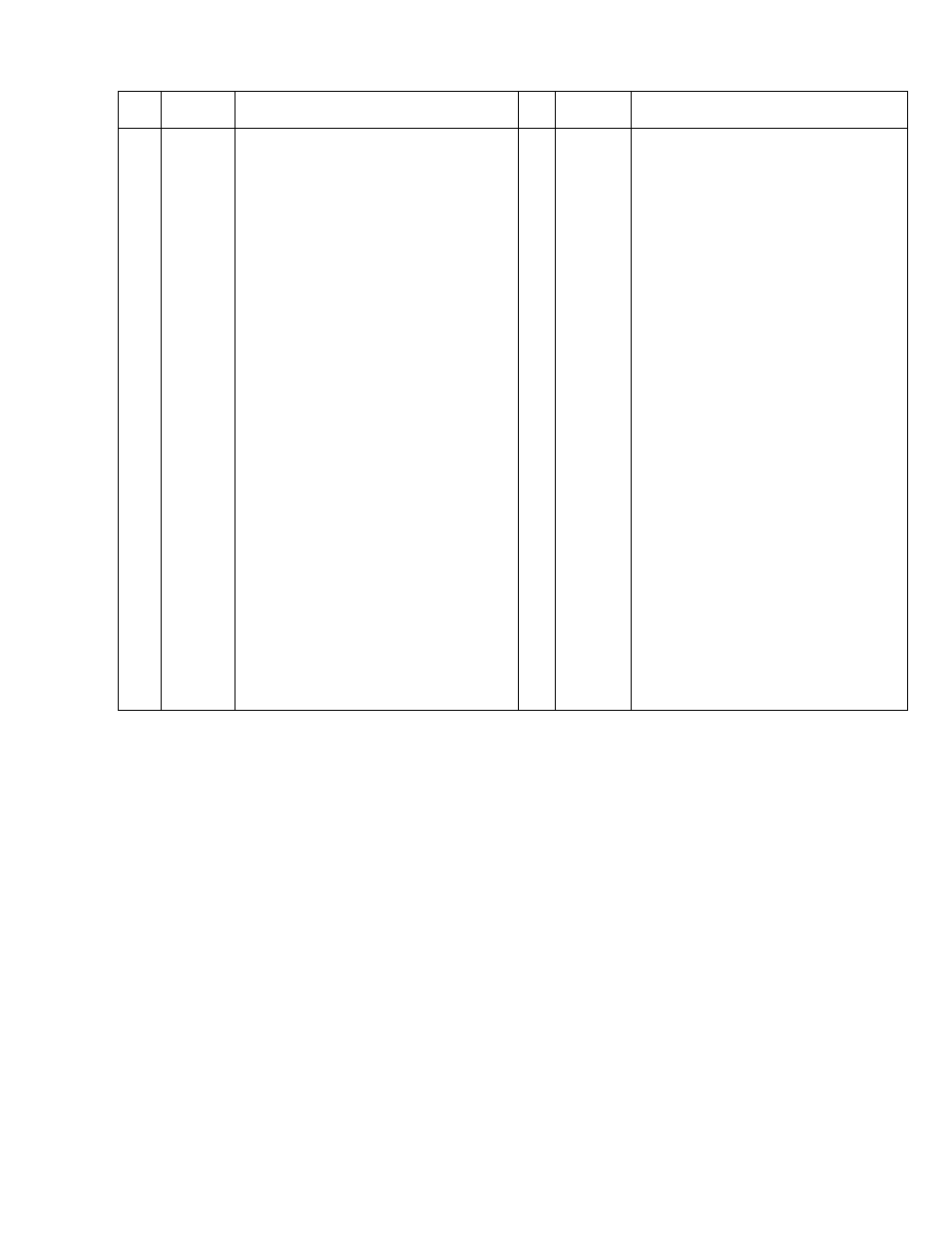

PARTS LIST FOR MODEL NO. 111-500

Ref.

No.

Port

No.

DESCRIPTION

R«(.

No.

Port

No.

DESCRIPTION

1

305-7071

Grips — Black

36

710-191

Hex tid. Cap Sew. 3/8-24 x 1-1/4

Ig.

2

310-8846

Throttle Control — Complete

(Heat Treated)

3

305-7470

Knob +

37

310-8835

Sin-ing Lever Assembly

4

310-8841

Throttle Control Bracket +

38

305-7520

Knob - Red

5

901-7627

Ferrule Assembly +

39

350-8809

Blade Reinforcement Plate

6

732-139

Conduit and Wire +

40

310-7492

Wheel Pivot Bar

7

710-606

HexHd. Cap Sew. 1/4-20 x 1-1/2

Ig. •

41

736-133

Flat Washer 3/8

ID *

8

712-107

Hex Centerlock Nut 1/4—20 thread *

42

712-116

Elastic Stop Nut 3/8—24 thread *

9

310-9364

Handle — Upper (2 Req’d)

43

901-7805

Blade Spindle Ass’y — Complete

10

710-106

HexHd. CapSew. 1/4—20 x 1-1/4 Ig. ♦

44

712-526

Speed Nu't

11

310-8334

Handle - Lower

45

710-116

HexHd. Cap Sew. 5/16—18 x 2

Ig. *

12

310-9060

Handle Bracket

46

710-473

Truss Hd. Mach. Sew. #10—24 x 1/2

Ig. *

13

710-209

Sems HexHd. Cap Sew. 3/8—16x5/8 Ig. *

47

736-147

External Lockwasher #10 Screw

*

14

501-9184

Wheel Assembly — Rear

48

310-9925

Pulley — 4” dia. — 1/2” bore

15

734-237

Tire-Rib Tread 14” dia. x 1-3/4”

49

736-921

Spring Lockwasher — 1/2” screw *

16

734-238

Wheel Assembly — Rear less Tire

50

712-922

Hex Jam Nut 1/2 — 20 thread *

17

748-147

Flange Bearing (2 Req’d Per Wheel)

51

754-116

V-Belt 42”

X

1/2”

*

18

738-114

Axle Bolt •— Rear

52

350-8295

Blade Soindle Cover

19

712-123

Hex Nut 5/16—24 thread

**

53

710-158

HexHd. Cap Sew. 5/16—24 x 1-1/4 Ig.

20

736-119

Spring Lockwasher 5/16 Screw

**

54

736-170

Lockwasher — Special

21

312-8125

Blade - 21”

55

711-250

Spacer

22

714-365

Key - Hi Pro

#

HP 505

**

56

756-121

Pulley — Engine — 4” dia.

23

710-117

Hex Head Cap Screw 5/16—24 x 1 Ig.

57

710-938

Allen Set Sew. Cup Pt. 1/4—28 x 1/4 Ig.*

(Heat Treated)

**

58

746-145

Cable Clip

24

736-217

SpringLockwasher3/8’^ Sew. Heavy Duty**

59

714-365

Key-m Pro

#

HP 505

*

A

25

710-489

Hex Head Cap Sew. 3/8—24 x 1-1/2 Ig. —

60

712-267

Hex Nut 5/16-18 thread *

(Heat Treated) **

61

711-240

Spindle A

26

748-189

Blade Adapter **

62

721-105

Seal A

27

736-105

Belleville Washer

63

741-107

Timktin Bearing — 3/4 Bore — lower A

28

736-112

Belleville Washer

64

719-120

Spindle Housing A

29

350-9169

Frame Assembly

65

741-120

Timken Bearing — 11/16 Bore—upper A

30

350-9069

Deck Assembly

66

736-154

Flat Washer A

31

310-7386

Washer

67

711-212

Sleeve

A

32

710-152

Hex Head Cap Screw 3/8—24 x 1 Ig.

68

901-|0769

Blade Adapter Kit/less Blade

33

501-9392

Wheel Assembly ~ Front

34

305-7006

Fortiflex Bearing

35

738-213

Axle Bolt

* For faster service obtain standard nuts, bolts and washers locally. If these items cannot be obtained locally, order by

part number and size as shown on parts list.

+ Included in Part No. 310-8846 Control-Throttle (complete).

** Part of Blade Adapter Kit 901-10759 less

A Included in Part No. 901-7805 Blade Spindle Ass’y (complete).

Blade (Complete).

ASSEMBLY

Your new mower is shipped completely assembled with the

exception of the handle.

1. Remove lawn mower and all parts from carton. Make

certain that all loose parts and literature are removed

from carton before carton is discarded.

2. Extend throttle control assembly, which is attached to

rear of mower and place on floor. CAUTION: Do not bend

or kink control wire.

3. (a) Snap lower handle into position on two lugs which

extend from the handle brackets mounted on the rear

of the frame assembly.

(b) Assemble the two upper handle parts with cap screws

and locknuts provided in parts bag. The yellow cap

screw should be used to attach throttle control assem

bly to upper handle as shown in diagram. Do not

tighten nuts.

(c) Attach upper handle assembly to lower handle with

cap screws and locknuts. Tighten all nuts.

(d) Secure control wire to lower handle with cable clips.

4. Check blade bolts for proper tightness.

5. See initial belt adjustment under Adjustment Section on

page “D”.

OPERATION

NOTE:

For shipping purposes your mower is set with the

v/heels in a low cutting height position. For best results

raise the cutting position until it is determined which

height is best for your lawn. See adjustments.

1. Service engine with gas and oil. See Engine Manual pack

ed with lawn mower for complete instructions for the care

and maintenance of engine.

Read Directions Carefully.

2. When ready to start engine, place throttle control lever,

on handle, in “Choke” position and start engine in

accordance with instructions in Engine Manual. After

engine starts, move throttle control lever, on handle, to

desired engine speed. The engine is stopped by placing

control lever on handle in the “Stop” position.

3. Be sure that lawn is clear of stones, sticks, wire or other

objects which could damage lawn mower or engine. For

best results and to insure more even grass distribution,

do not mow when lawn is excessively wet.

FORM NO. 770-2874C